Axle assembly driven by new energy

A technology for driving axles and new energy, applied in electric vehicles, control drives, vehicle components, etc., can solve the problems of electronic differentials that do not have the technical maturity, complex technology, and have not been widely used, so as to ensure safety. The effect of comfortable driving, easy application, and strong circuit versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

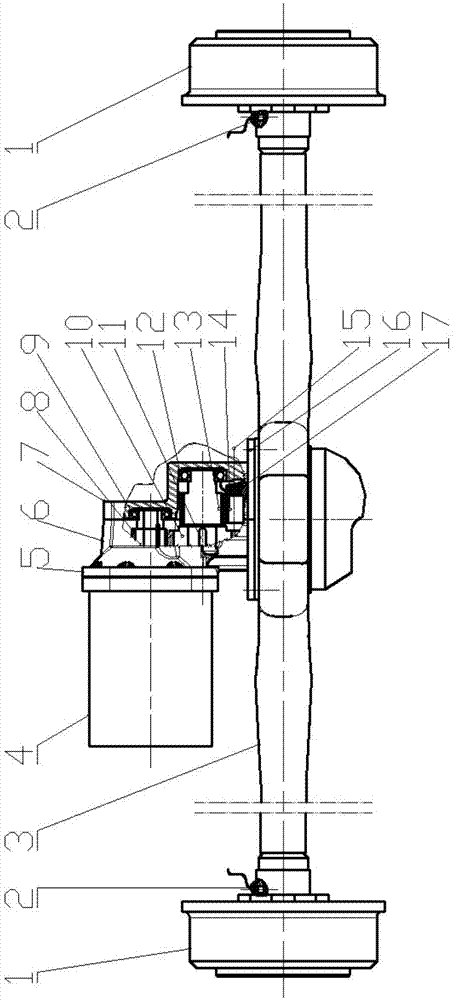

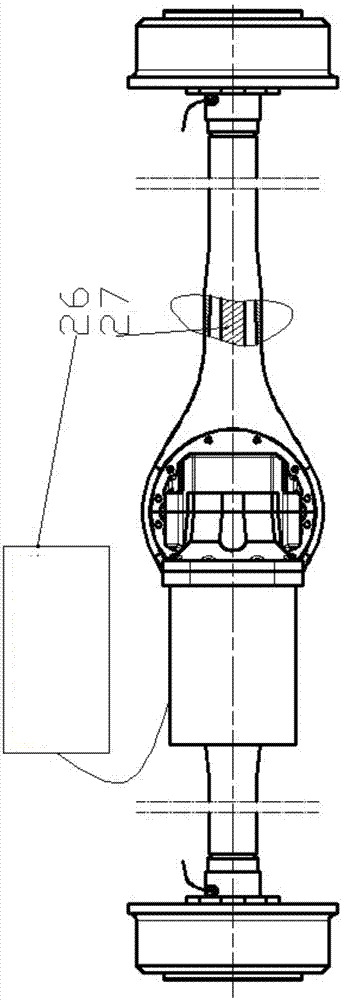

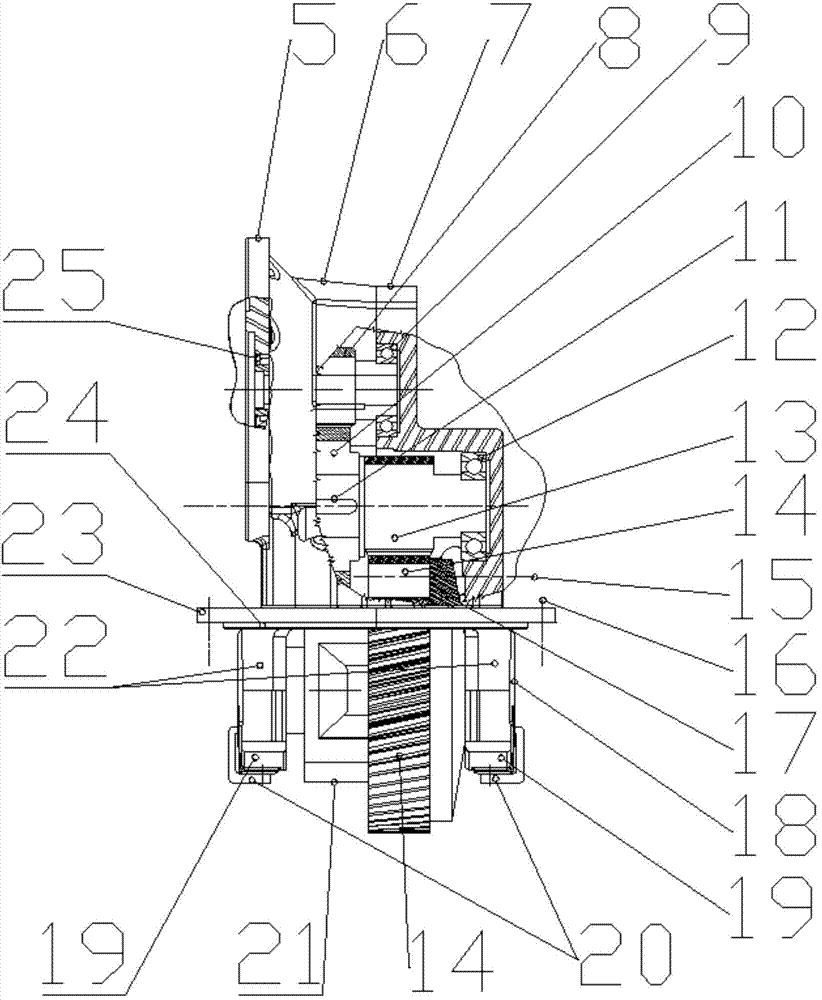

[0022] see figure 1 , figure 2 and image 3 , 1-brake drum, 2-speed sensor, 3-integral axle housing, 4-brushless DC motor, 5-left reducer housing boss, 6-left reducer housing, 7-right reducer housing Body, 8-input gear shaft, 9-input shaft bearing, 10-first-stage large gear, 11-key, 12-intermediate shaft bearing, 13-intermediate gear shaft, 14-output gear, 15-output gear fixing bolt, 16-Reducer mounting bolts, 17-Differential boss, 18-Differential adjustment nut, 19-Differential bearing cap, 20-Differential bearing cap lock, 21-Differential assembly, 22 -Differential gear bearing seat, 23-The upper boss of the reducer housing, 24-The lower boss of the reducer housing, 25-Oil seal, 26-Brushless DC motor controller and wiring harness, 27-Half shaft.

[0023] A new energy drive axle assembly, including a brushless DC motor controller 26, a brushless DC motor 4, a secondary reducer assembly, an integral axle housing 3, a half shaft 27 and a brake drum 1, characterized in that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com