Automobile channel assembly part

A technology of assembly parts and channels, applied in the field of auto parts, can solve the problems of water ingress and poor sealing, and achieve the effect of ensuring sealing, simple structure, no leakage of water and dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to better understand the technology of the present invention, the following will be described in conjunction with the accompanying drawings and embodiments. The description of the following examples is only exemplary and explanatory, and does not have any limiting effect on the protection scope of the present invention.

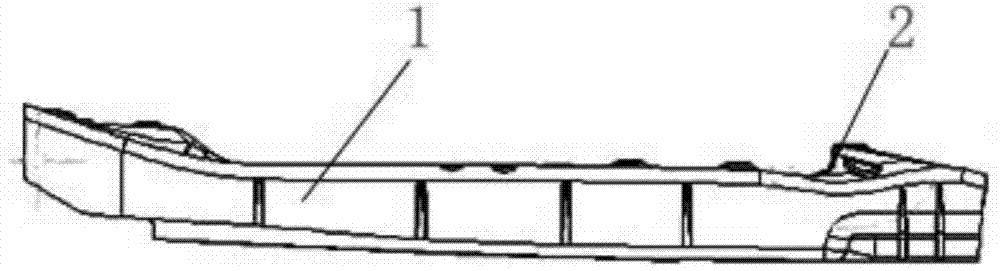

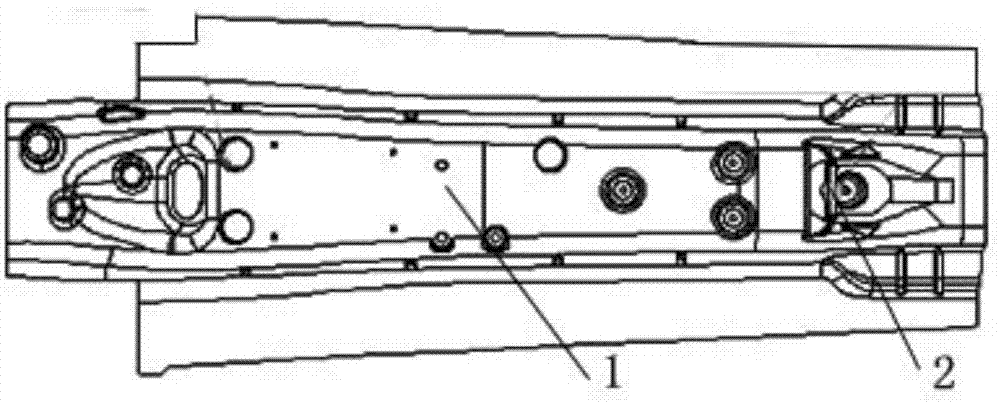

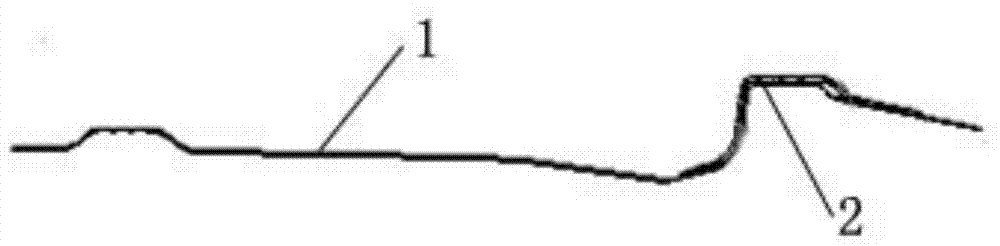

[0013] like Figure 1-Figure 3 The vehicle channel assembly shown in the figure includes a channel housing 1, the inner surface of the housing 1 is an inner groove structure, and the outer surfaces of both ends of the housing 1 are provided with protrusion structures, and the protrusion structure on the right is the handbrake installation point 2 The housing 1 is provided with a plurality of installation holes, and the housing 1 is provided with flanges, wherein the surface of the handbrake installation point 2 is coated with sealant.

[0014] In this embodiment, the handbrake installation point 2 is a protrusion with a concave structure, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com