Large-scale steel box beam ashore construction method

A construction method and technology of steel box girders, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of high construction cost, expensive use of floating cranes, failure of floating cranes to reach the normal lifting position, etc., and save money , The effect of shortening the project cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

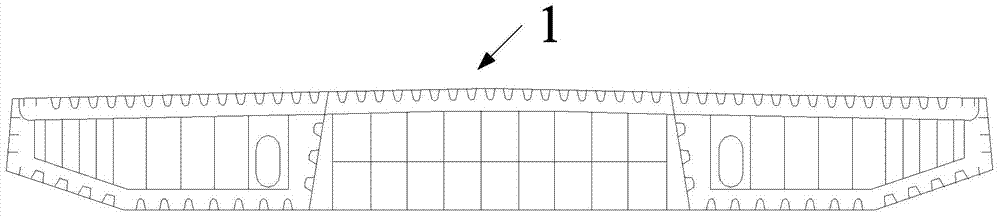

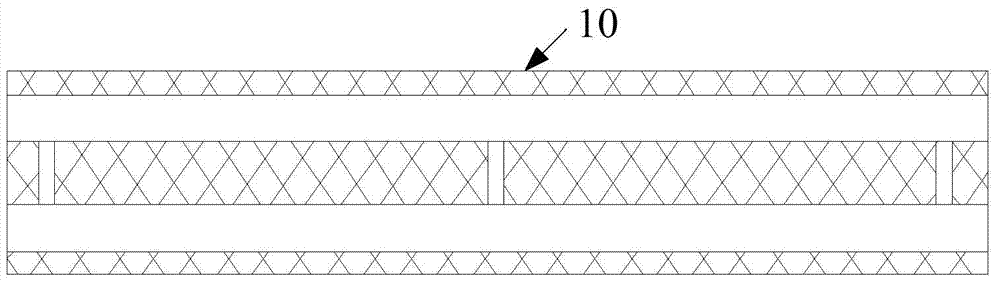

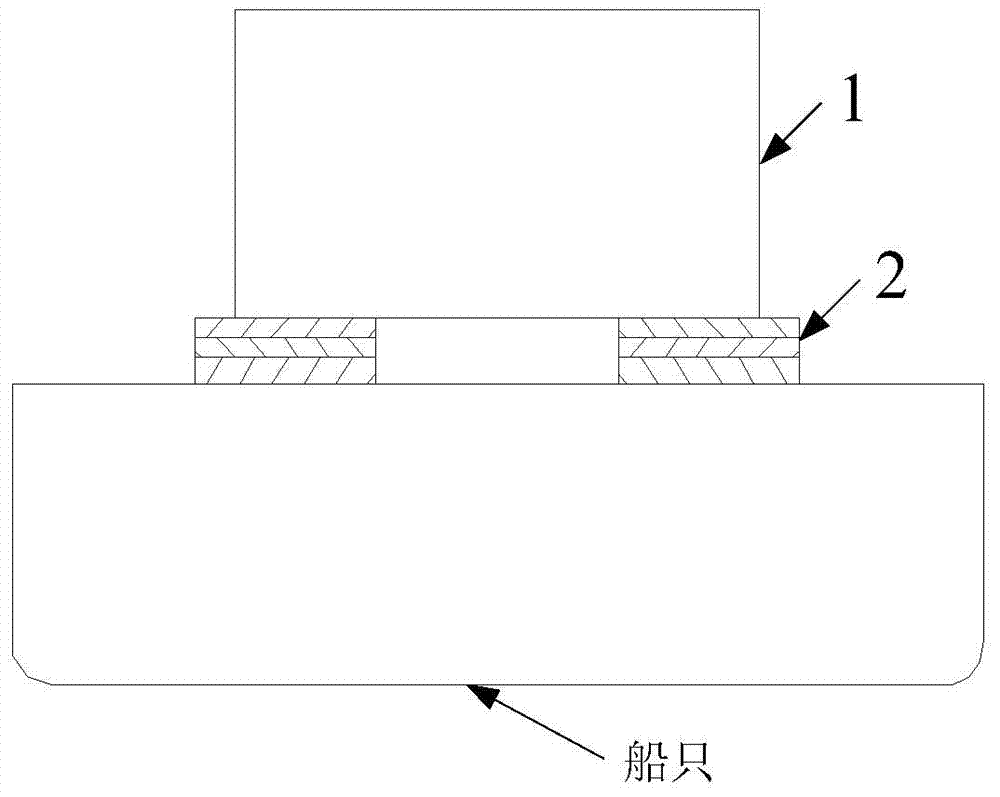

[0036] The present invention provides a large-scale steel box girder landing construction method, including the steps: S1, steel box girder 1 is transported by water, the steel box girder 1 is transported by water, and the steel box girder 1 is placed by carrying wooden pier 2 and air bag 3 On the deck of the ship; S2, setting of the positioning device, setting of the ground anchor 4 on the shore, and there are at least four ground anchors 4; Sliding ramp 6 is extended on the shore, and slide rail 7 is laid on the sliding ramp 6; S4, the air bag is supported on the shore, and the air bag is used to support the steel box girder 1, and the steel box girder 1 is transferred to the shore by the air bag. ashore.

[0037] In the above method, the airbag 3 is used to realize the lifting, transporting, and up and down ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com