A device for measuring end face deformation of face milling tool based on double pulse laser

A face milling tool and double pulse technology, applied in the field of face milling tool end face deformation measurement device, can solve the problem of lack of tool end face deformation measurement, etc., and achieve the effect of strong vibration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

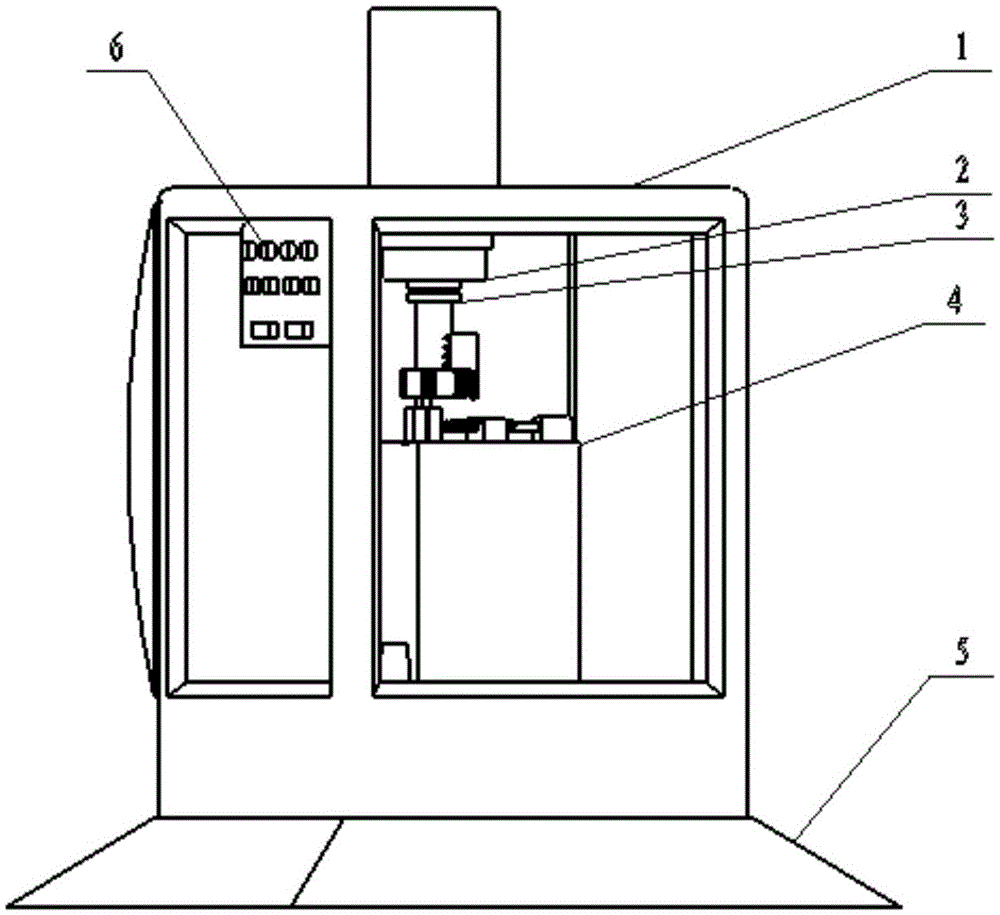

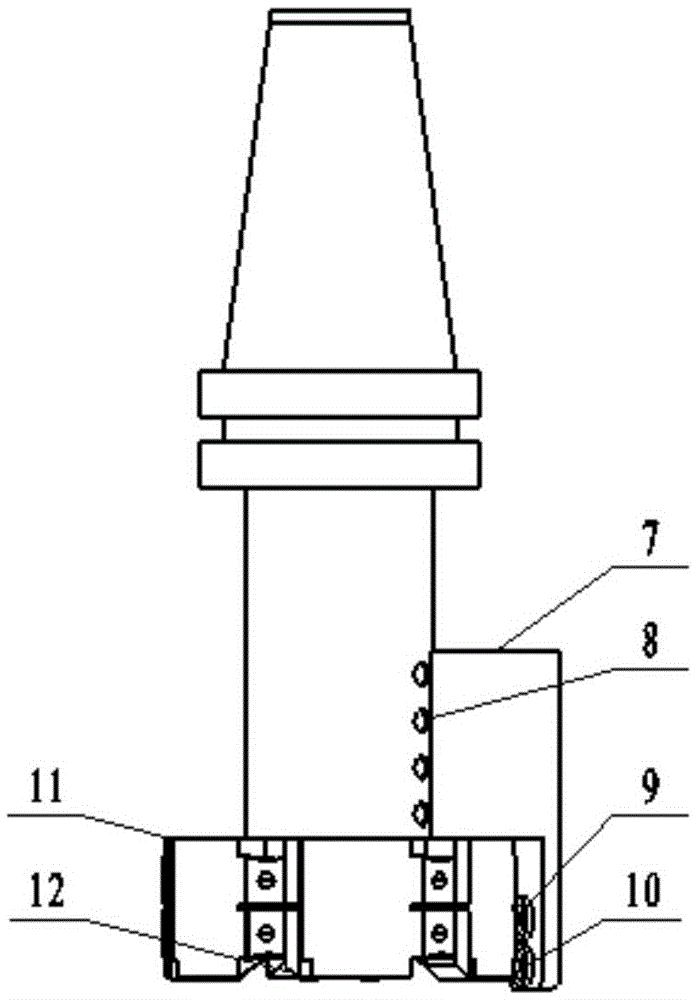

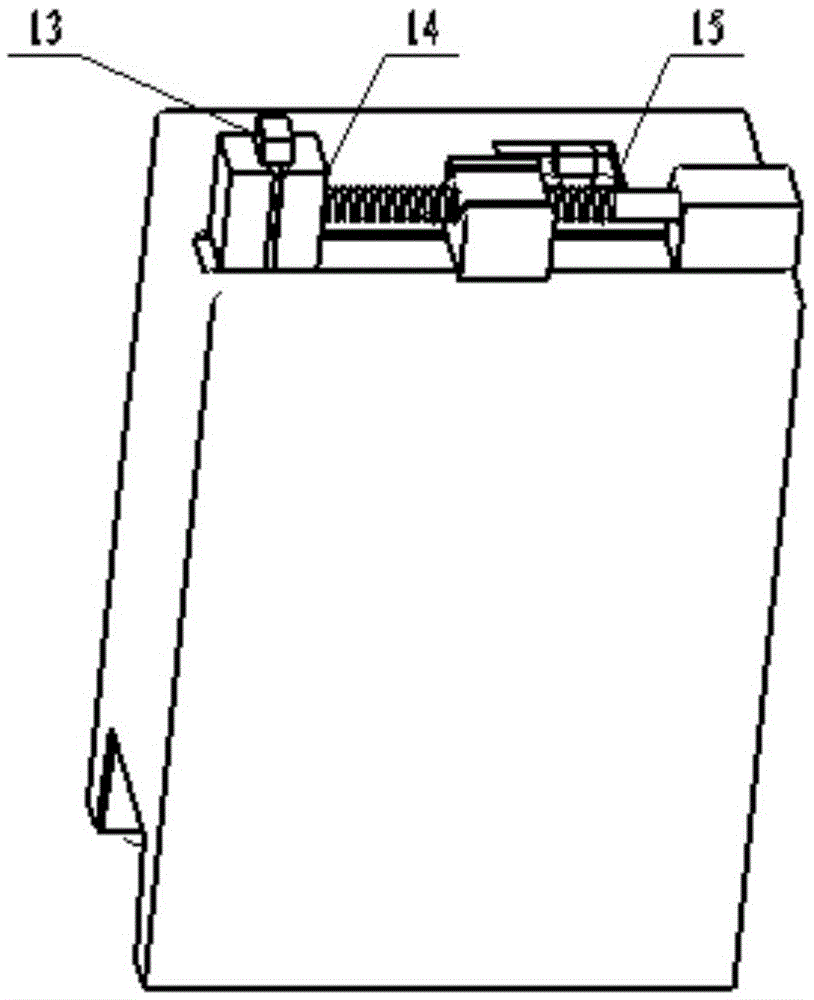

[0010] As shown in the figure, a face milling tool end face deformation measurement device based on a double pulse laser consists of a spindle box 1, an electric spindle 2, a connecting tool bar 3, a fixed platform 4, a base 5, a controller 6, and a double pulse laser 7 , set bolt 8, laser emitting end 9, CCD lens 10, face milling cutter head 11, milling cutter 12, milling workpiece 13, clamping device 14, ball screw 15; it is characterized in that: spindle box 1 is connected with base 5 Together, the electric spindle 2 and the controller 6 are fixed on the upper end of the spindle box 1, the electric spindle 2 is equipped with the connecting knife bar 3, and the double pulse laser 7 is firmly fixed on the connecting knife bar 3 through the tightening bolt 8, and the double pulse A laser emitting end 9 and a CCD lens 10 are installed on the laser 7, a face milling cutter disc 11 is installed on the connecting tool bar 3, a milling cutter 12 is provided on the face milling cutte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com