Compact dry toilet installation

A technology for facilities and toilets, applied in the field of compact dry toilet facilities, which can solve the problems of not providing safety and large space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

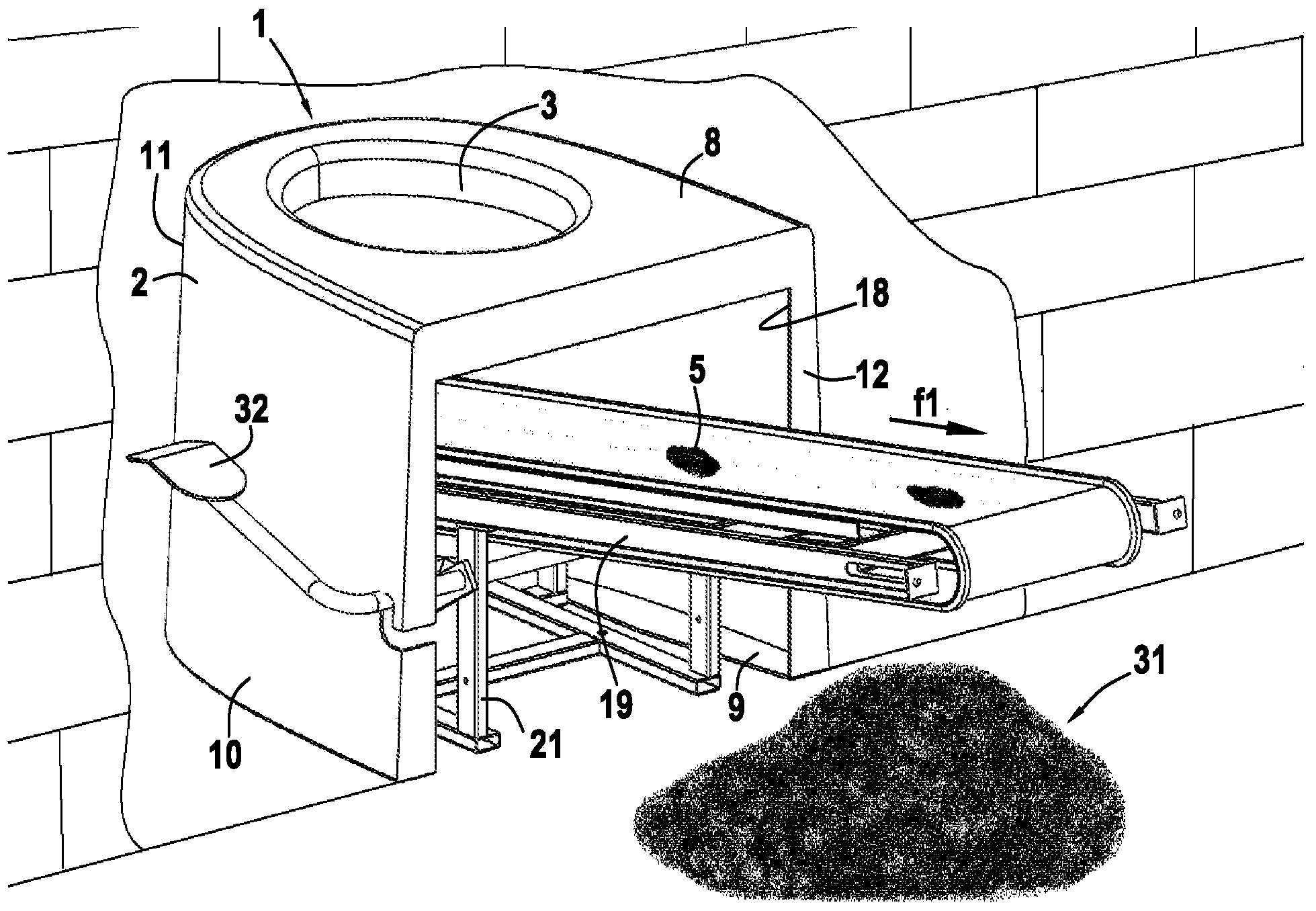

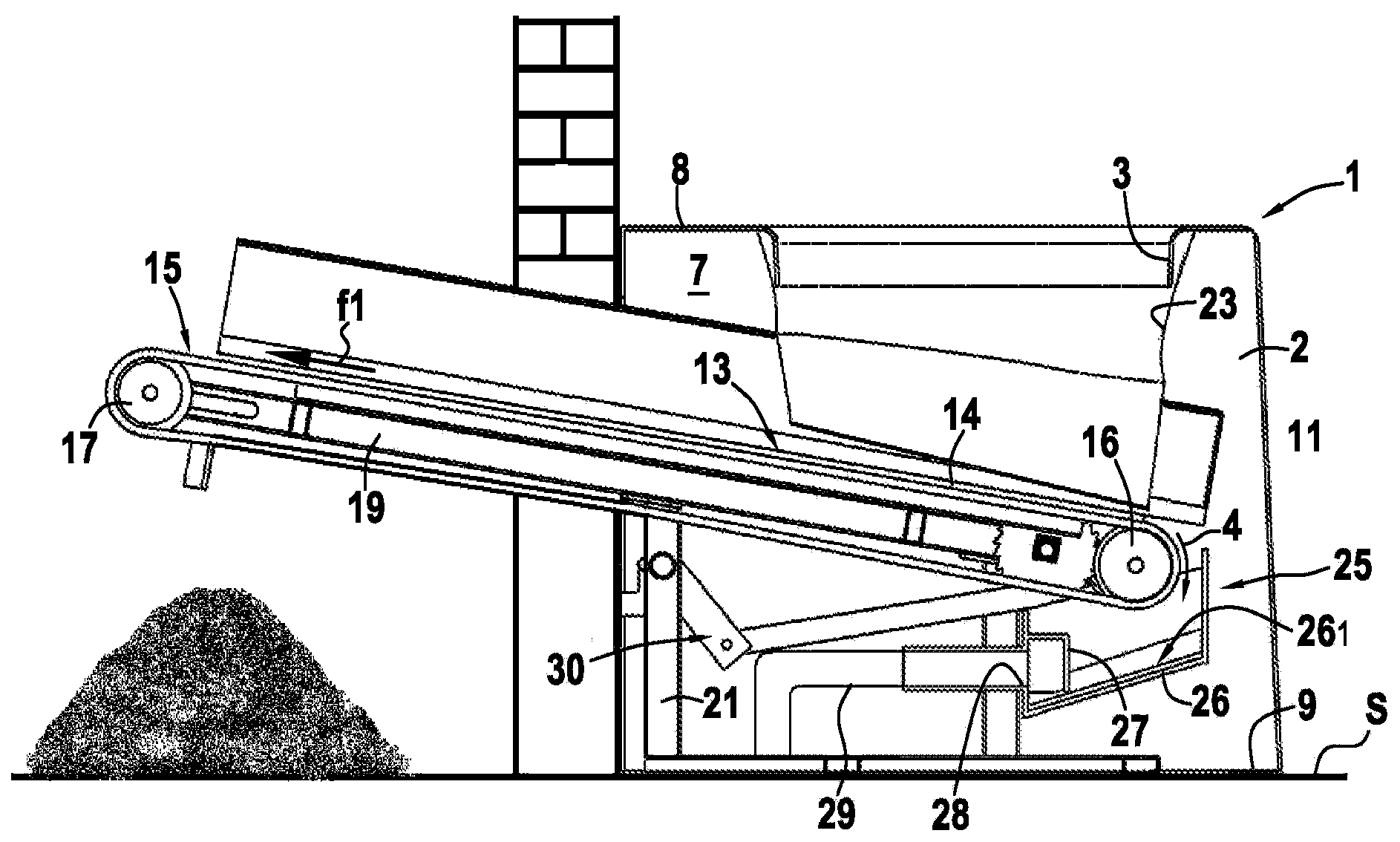

[0038] Such as figure 1 with figure 2 As can be seen more clearly in , the subject matter of the present invention is a compact dry toilet installation 1 comprising a toilet seat 2 defined for the discharge of liquid effluents 4 (such as urine) and solid waste 5 (such as excreta, toilet paper or sanitary napkins)3.

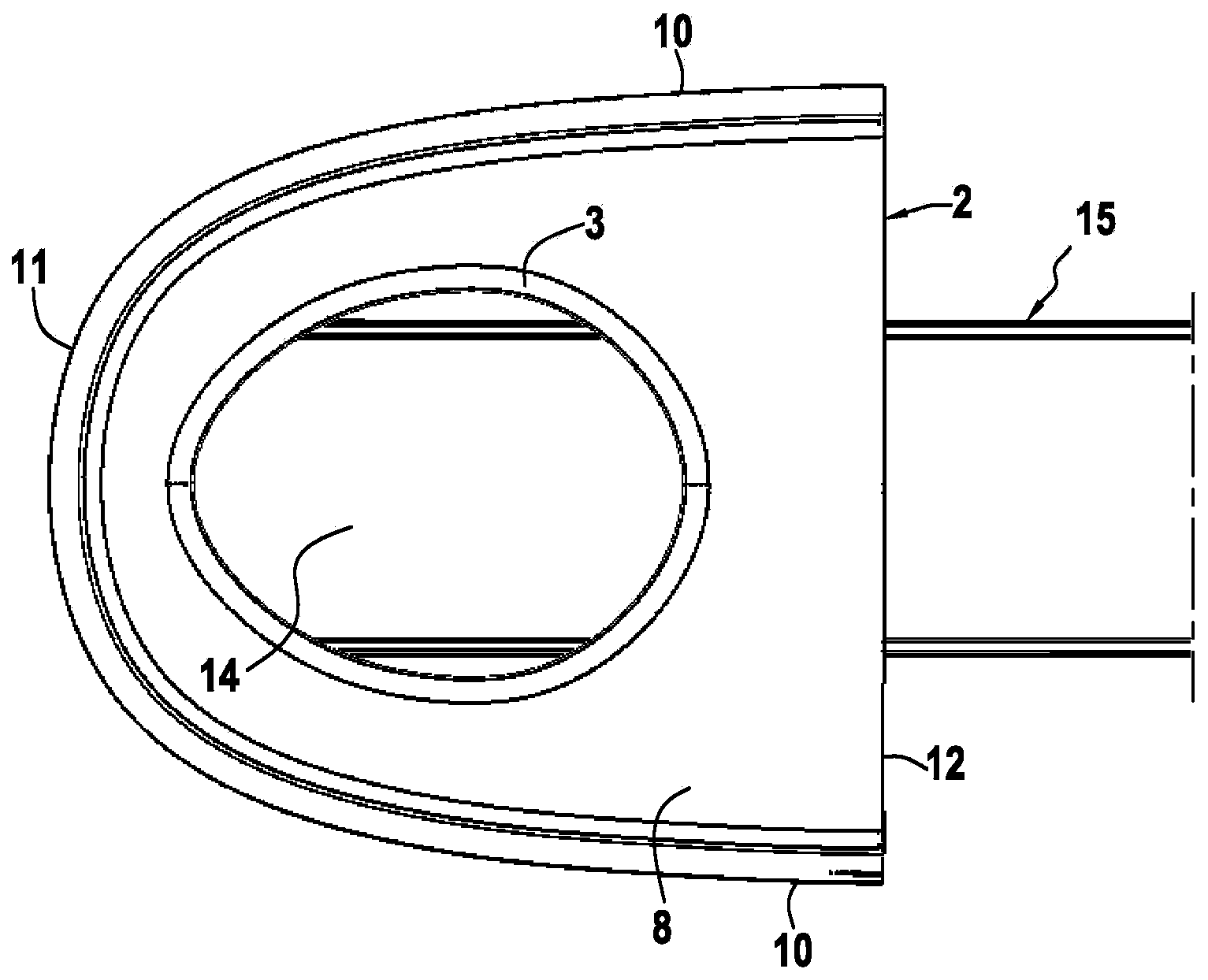

[0039] The toilet seat 2 is in the form of a hollow body defining an internal volume 7 . The seat 2 has an upper surface 8 on which the discharge opening 3 is arranged to extend parallel to a lower surface 9 which rests on the ground S. As shown in FIG.

[0040] The upper surface 8 and the lower surface 9 are connected together by side walls 10 , front 11 and rear 12 . exist Figure 1 to Figure 3 In the example shown, the front 11 is a circle, while the Figure 4 In the example shown, the front face 11 is flat. Preferably, the lower bearing surface 9 is defined as a peripheral boundary extending at right angles from the side walls 10 and the front face 11 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com