Olefin Block Copolymer

A technology of olefin block and copolymer, which is applied in the field of olefin block copolymer, and can solve problems such as easy deterioration of processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, a detailed description will be given of the olefin block copolymer and the preparation method thereof according to the embodiment of the present specification. However, these embodiments are provided for illustration only and are not intended to limit the scope of the present invention. Furthermore, it is obvious to those skilled in the art that these embodiments can be modified in various ways.

[0019] Unless otherwise stated, some terms used throughout the specification may be defined as follows.

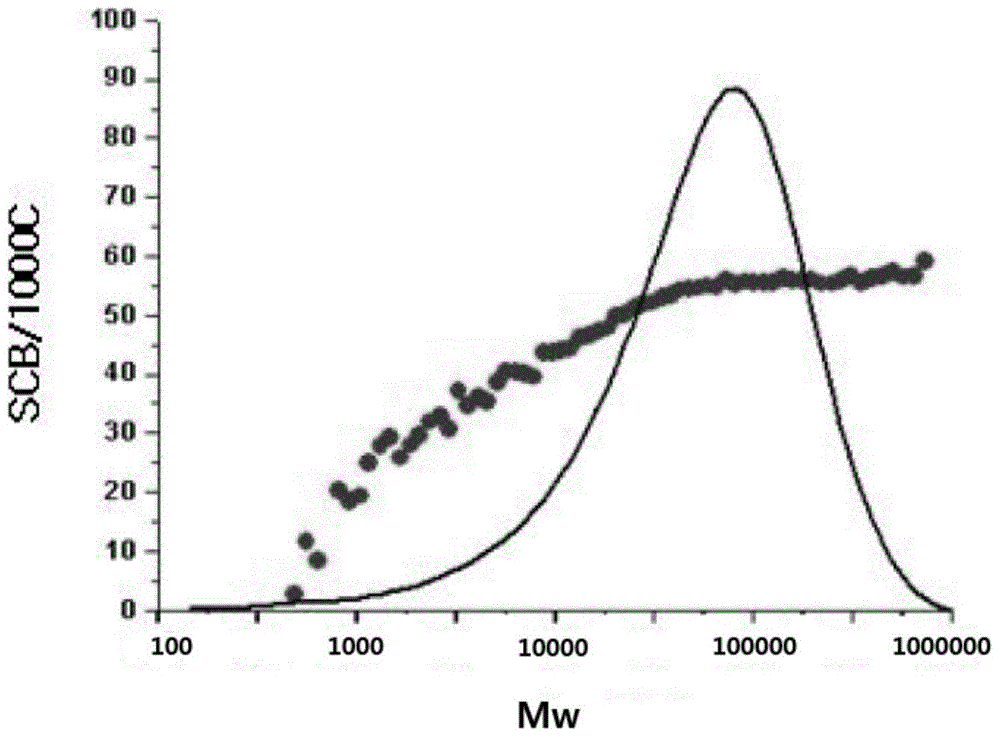

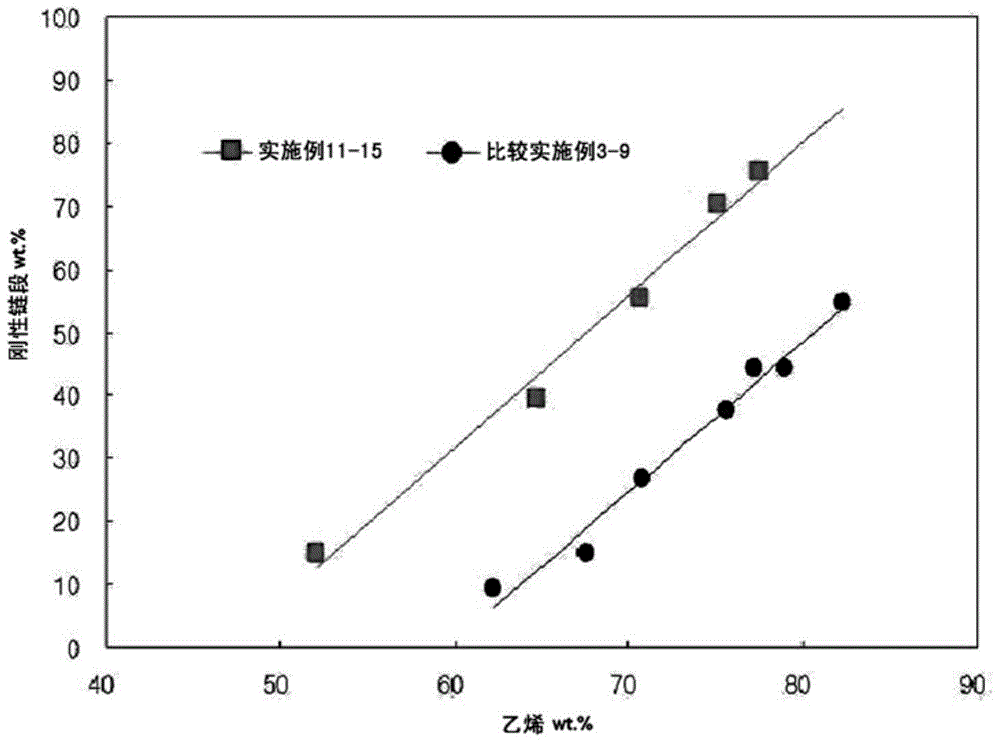

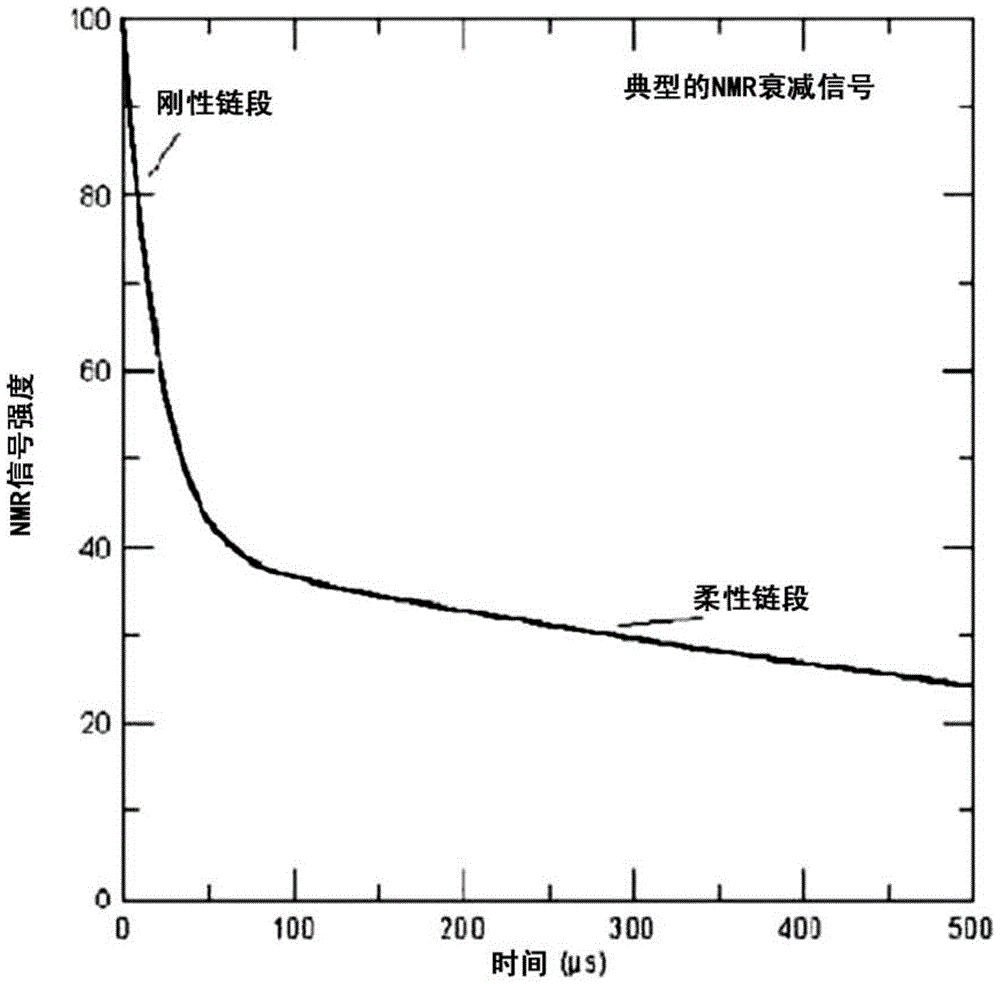

[0020] The term "(olefin) block copolymer" as used herein refers to a copolymer of ethylene or propylene and an alpha-olefin, wherein the copolymer comprises a plurality of blocks or segments of repeating units comprising For example, the content (weight fraction) of repeating units derived from ethylene (or propylene), the content (weight fraction) of repeating units derived from α-olefins, crystallinity, density or melting temperature of multiple blocks or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com