Variable turbine/compressor geometry

A geometry, compressor technology, used in machines/engines, gas turbine installations, mechanical equipment, etc., to solve problems such as difficult maneuverability, high exhaust gas turbochargers, weakening of variable geometry turbine/compressor life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

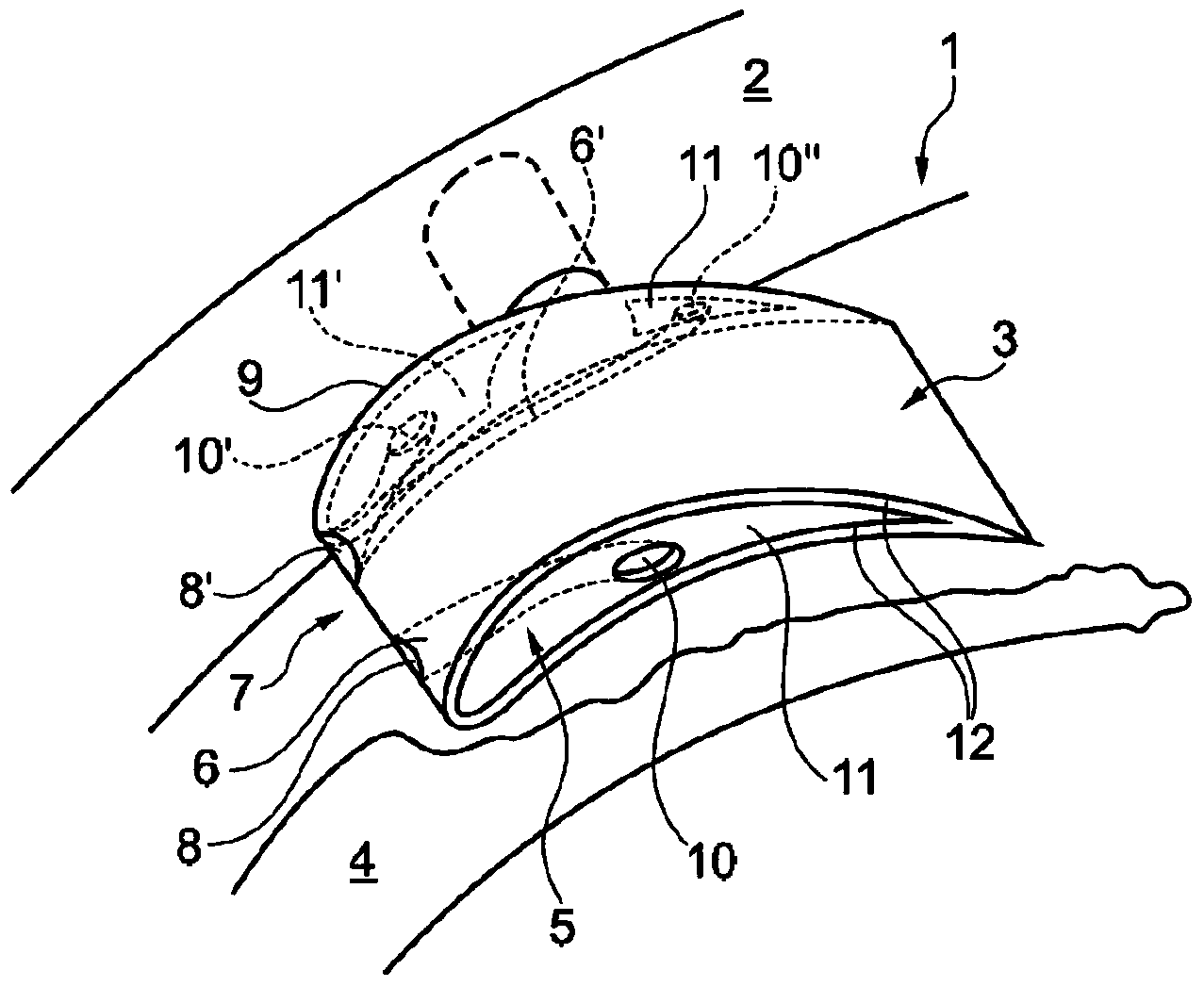

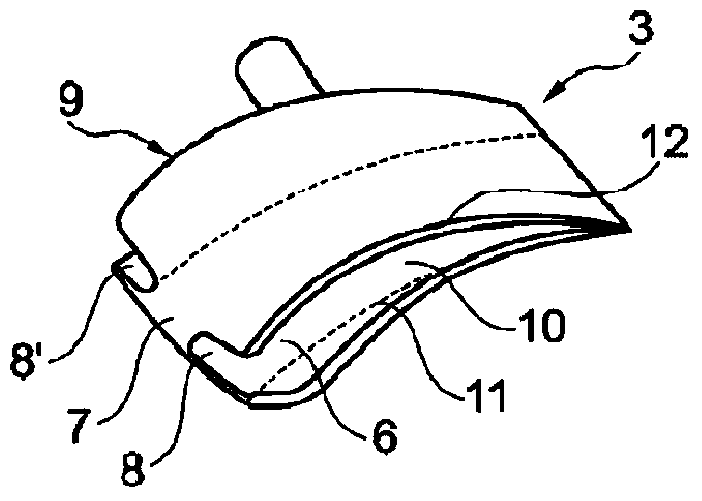

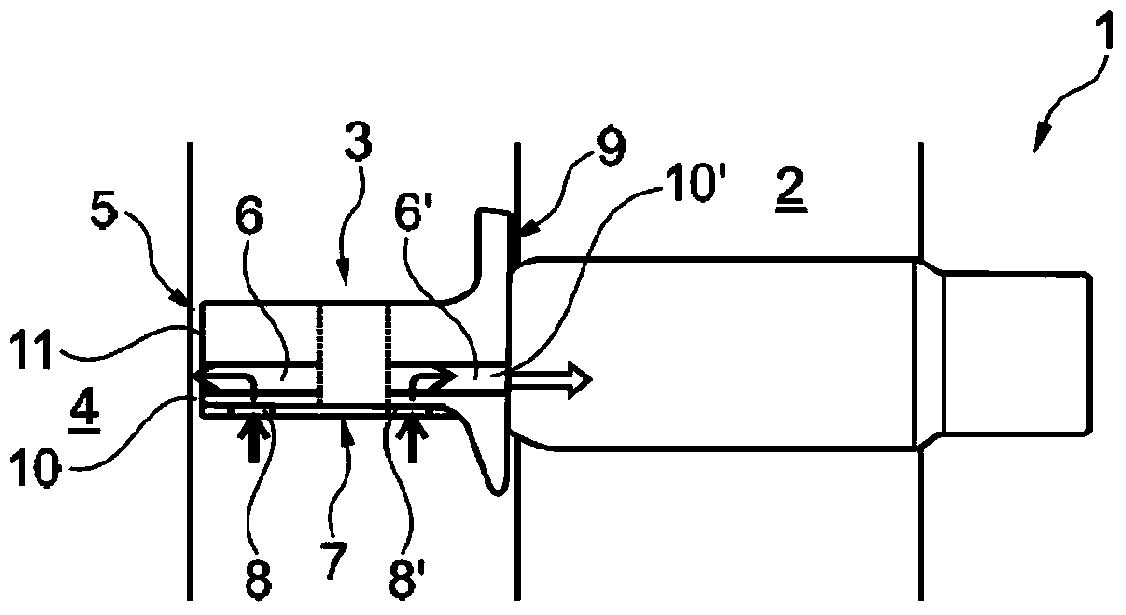

[0018] Refer to Figure 1 and figure 2 , the inventive variable geometry turbine / compressor 1 of a gas turbocharger for an internal combustion engine of a motor vehicle includes a vane bearing ring 2 on which guide vanes 3 are mounted. The cover plate 4 is arranged on the surface of the guide vane 3 , in order to better show the surface end 5 of the guide vane 3 facing the cover plate 4 , FIG. 1 only shows a part of the cover plate 4 . According to the invention, at least one air guide channel 6 , generally an air guide channel, runs through at least one guide vane 3 , comprising at least one air inlet 8 , 8 ′ in the area of the lateral projection 7 and one located towards the cover. Discharge openings 10, 10', 10" on the surface end 5 of the disc 4 and / or on the bottom 9 towards the blade bearing ring 2, and thereby produce a reduction in the surface end 5 and / or on the bottom 9 Gas buffers for friction, especially air buffers.

[0019] Obviously, the guide vane 3 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com