Soybean salted product and manufacturing method

A production method and technology of pickled products, which are applied in the field of soybean pickled products and production, and can solve the problems of large nutrient loss and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The invention provides a pickled soybean product, which comprises the following raw materials in mass ratio: 400 parts of soybeans, 100 parts of watermelon peel, 60 parts of table salt, 0.6 parts of pepper powder, 2 parts of star anise powder, and 1 part of cumin powder , 0.5 parts of minced ginger, and 5 parts of sesame oil. Soybeans of the present invention are preferably wet soybeans with a moisture content of 60%.

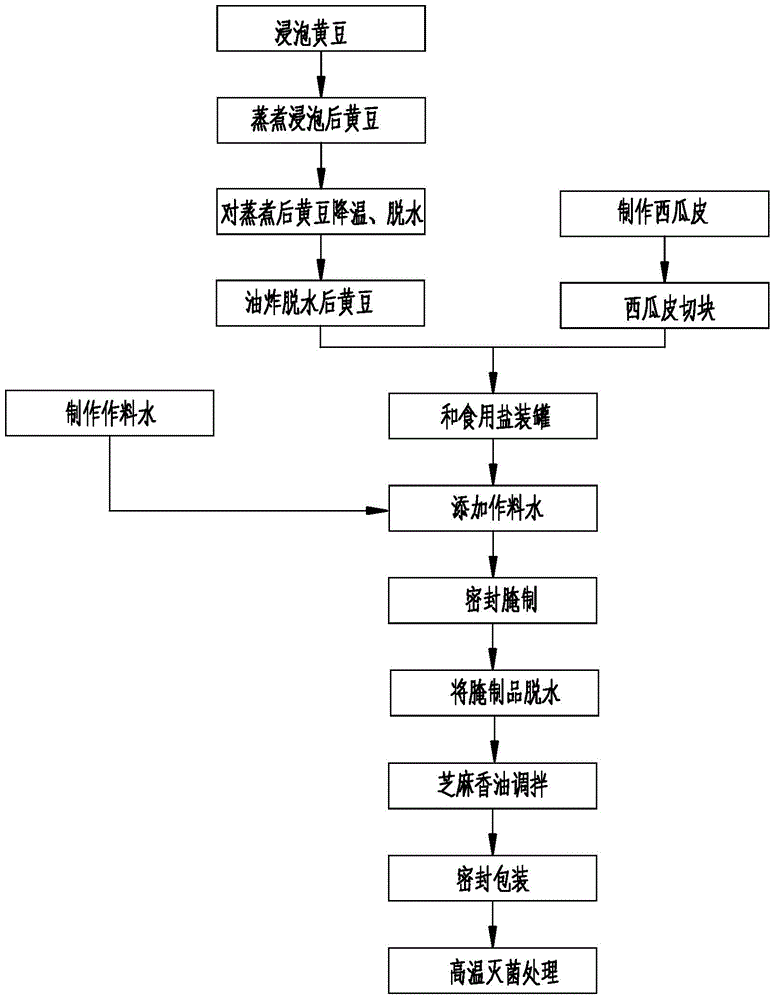

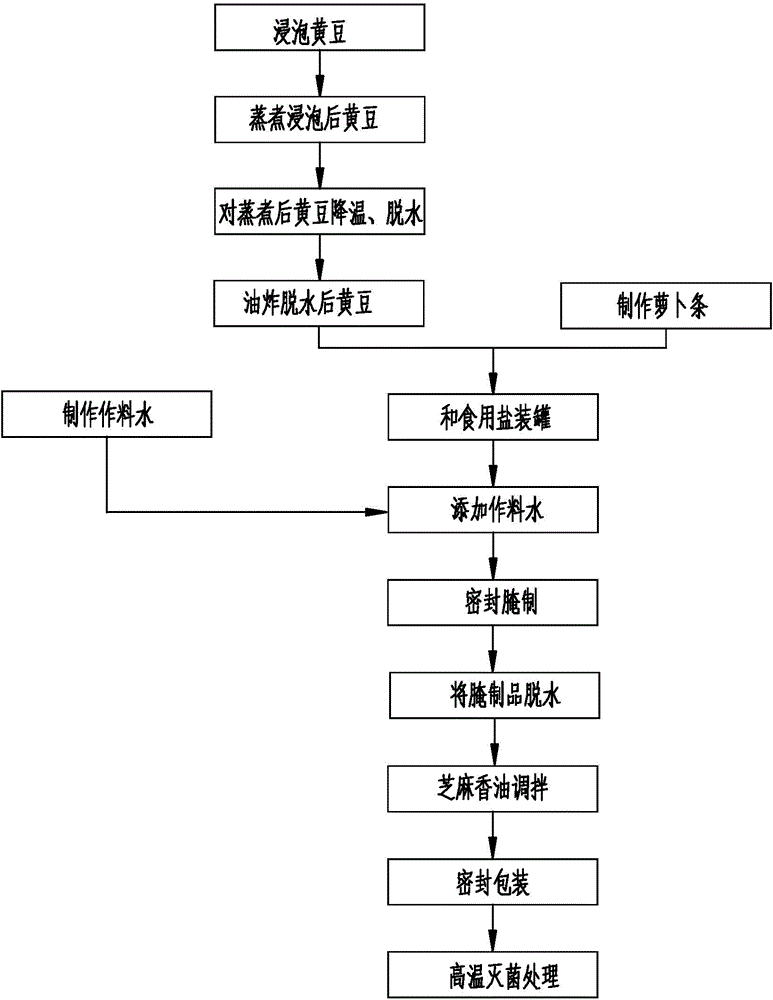

[0031] Such as figure 1 As shown, the present invention also provides a preparation method of the above-mentioned soy pickled product, comprising the following steps,

[0032] The step of soaking soybeans; the temperature of the soaking step is 15° C., and the time of the soaking step is 2.5 hours. Let soybeans fully absorb and expand in room temperature water. If the temperature is too low, the soaking time will be increased. If the temperature is too high, unnecessary nutrient loss will be caused.

[0033] The step of steaming the soaked soybeans; t...

Embodiment 2

[0047] The invention provides a pickled soybean product, which comprises the following raw materials in mass ratio: 600 parts of soybeans, 300 parts of watermelon peel, 100 parts of table salt, 1.0 parts of pepper powder, 6 parts of star anise powder, and 5 parts of cumin powder , 1.0 parts of minced ginger, 15 parts of sesame oil. Soybeans of the present invention are preferably wet soybeans with a moisture content of 50%.

[0048] Such as figure 1 As shown, the present invention also provides a preparation method of the above-mentioned soy pickled product, comprising the following steps,

[0049] The step of soaking soybeans; the temperature of the soaking step is 25° C., and the time of the soaking step is 3.0 hours.

[0050] The step of steaming the soaked soybeans; the step of steaming treatment includes the step of steaming at high heat for 5 minutes at normal pressure and the step of cooking at low heat for 5 minutes after steaming at high fire.

[0051] The steps of...

Embodiment 3

[0064] The invention provides a pickled soybean product, which comprises the following raw materials in mass ratio: 500 parts of soybeans, 200 parts of watermelon peel, 80 parts of table salt, 0.8 parts of pepper powder, 4.0 parts of star anise powder, and 3.0 parts of cumin powder , 0.7 parts of ginger powder, and 10 parts of sesame oil. The soybeans are selected from wet soybeans with a moisture content of 55%.

[0065] Such as figure 1 As shown, the present invention also provides a preparation method of the above-mentioned soy pickled product, comprising the following steps,

[0066] A step of soaking soybeans; the temperature of the soaking step is 20° C., and the time of the soaking step is 2.8 hours.

[0067] The step of steaming the soaked soybeans; the step of steaming treatment includes the step of steaming at high heat for 5 minutes at normal pressure and the step of cooking at low heat for 3 to 5 minutes after steaming at high fire.

[0068] The steps of cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com