Layered seasoning method

A kind of seasoning and type technology, applied in the field of layered taste, can solve the problem of single taste, achieve the effect of enriching the taste, changing the single taste, and optimizing the preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

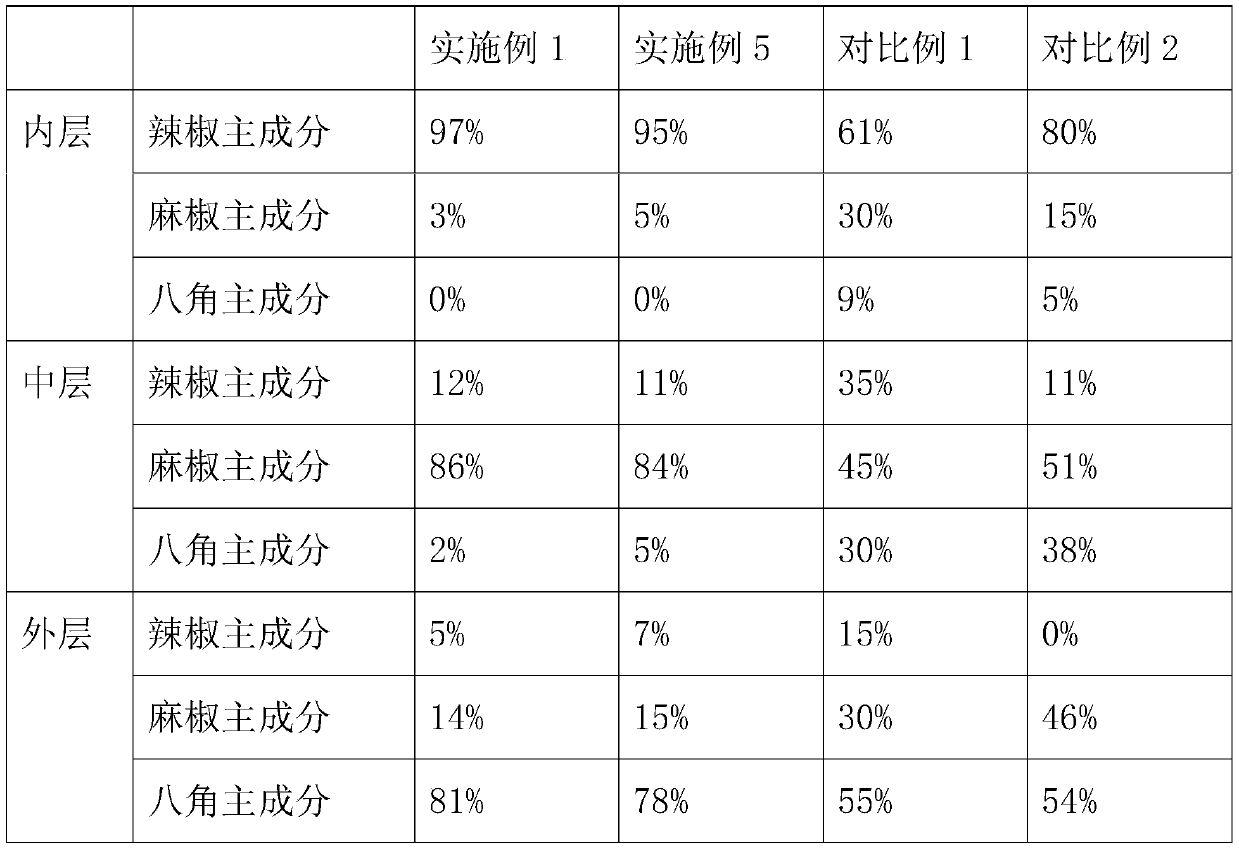

Examples

Embodiment 1- 3

[0029] Example 1 - Triple Flavored Peanuts

[0030] A layered approach that includes:

[0031] Step 1: Select peanuts with full grains, and then soak them in clear water or salt water for 4-6 hours to increase the volume of peanuts by 20-50%, so that the peanuts can fully absorb water and swell;

[0032] Step 2: Put the peanuts prepared in Step 1 in a frying equipment, and fry them at 120° C. for 20 minutes, so that the moisture inside the peanuts evaporates rapidly, and obtain fried peanut raw materials;

[0033] Step 3: Use a peanut stripper to remove the red coat of peanuts to obtain peanuts without red coats, and then add peanuts to a vacuum environment for centrifugal deoiling, effectively reducing the oil content in peanuts, so as to obtain peanuts filled with small pores Swell peanuts.

[0034] Step 4: Configure the first oil-soluble seasoning. In this embodiment, the first oil-soluble seasoning is composed of chili essential oil and peanut oil with a mass ratio of 0....

Embodiment 2- 3

[0037] Example 2 - Three Layers of Savory Almonds

[0038] A layered approach that includes:

[0039] Step 1: Select almonds with plump particles, and then soak them in water or salt water for 4-6 hours to increase the volume of almonds by 20-50%, so that the almonds can fully absorb water and swell;

[0040] Step 2: Put the almonds prepared in step 1 in a frying equipment, and fry them at 130° C. for 15 minutes, so that the moisture inside the almonds evaporates rapidly, and fried almonds are obtained;

[0041]Step 3: adding almonds to centrifugal deoiling in a vacuum environment, effectively reducing the oil content in almonds, so as to obtain expanded almonds filled with fine pores.

[0042] Step 4: Configure the first oil-soluble seasoning. In this embodiment, the first oil-soluble seasoning is composed of tangerine peel seasoning oil and soybean oil with a mass ratio of 0.05:100. Heat the wok and put the first Oil-soluble flavorings and expanded almonds, the first oil-s...

Embodiment 3

[0045] Example 3 - Two Layers of Savory Peanuts

[0046] A layered approach that includes:

[0047] Step 1: Select peanuts with full grains, and then soak them in clear water or salt water for 4-6 hours to increase the volume of peanuts by 20-50%, so that the peanuts can fully absorb water and swell;

[0048] Step 2: Put the peanuts prepared in step 1 in a frying equipment, and fry them at 160° C. for 20 minutes, so that the moisture inside the peanuts evaporates rapidly, and obtain fried peanut raw materials;

[0049] Step 3: Use a peanut stripper to remove the red coat of peanuts to obtain peanuts without red coats, and then add peanuts to a vacuum environment for centrifugal deoiling, effectively reducing the oil content in peanuts, so as to obtain peanuts filled with small pores Swell peanuts.

[0050] Step 4: Configure the first oil-soluble seasoning. In this embodiment, the first oil-soluble seasoning is composed of tangerine peel seasoning oil and soybean oil with a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com