Elastic seal automatic sprinkler head

An elastic sealing and automatic technology, which is applied in fire rescue and other fields, can solve the problems of unsatisfactory sealing performance and single sealing ring structure, achieve good sealing performance, improve the overall sealing performance, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

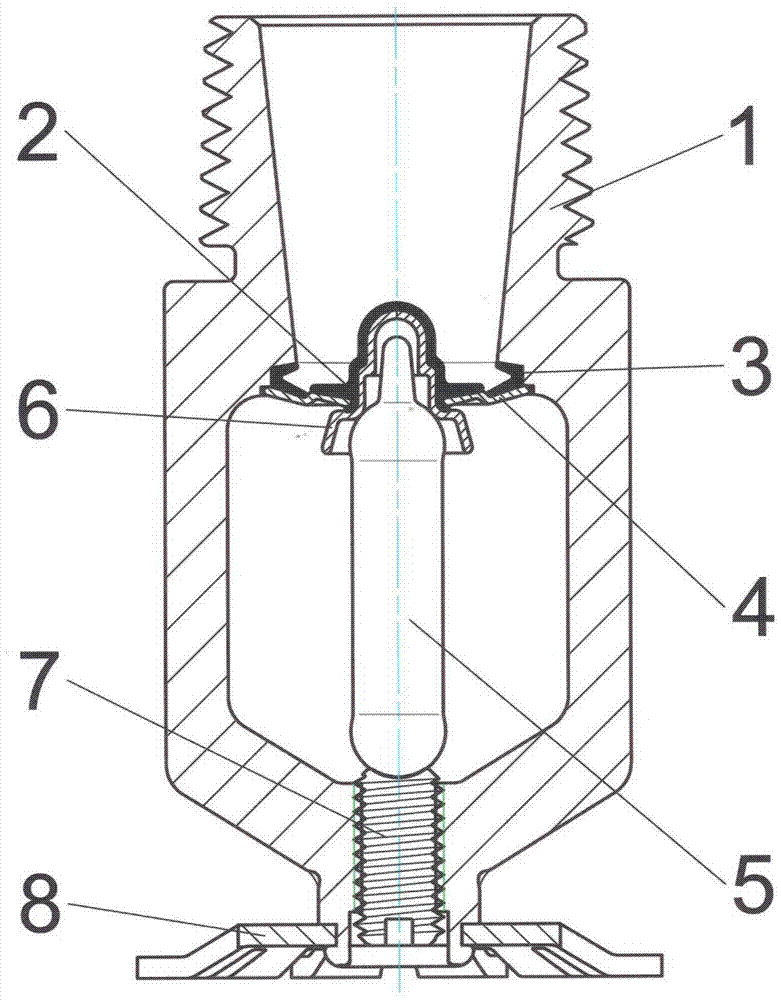

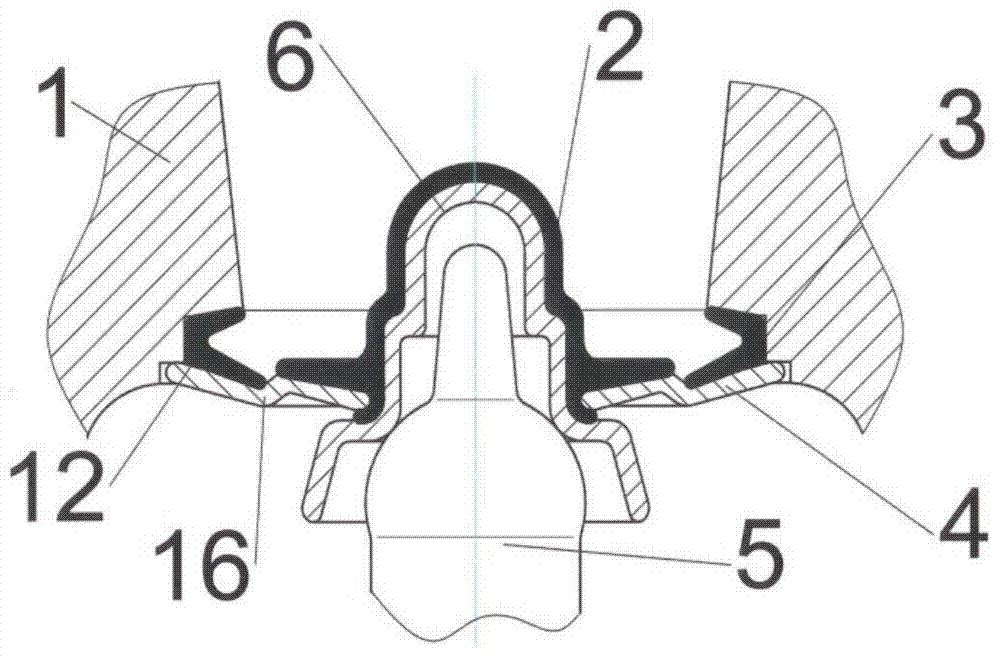

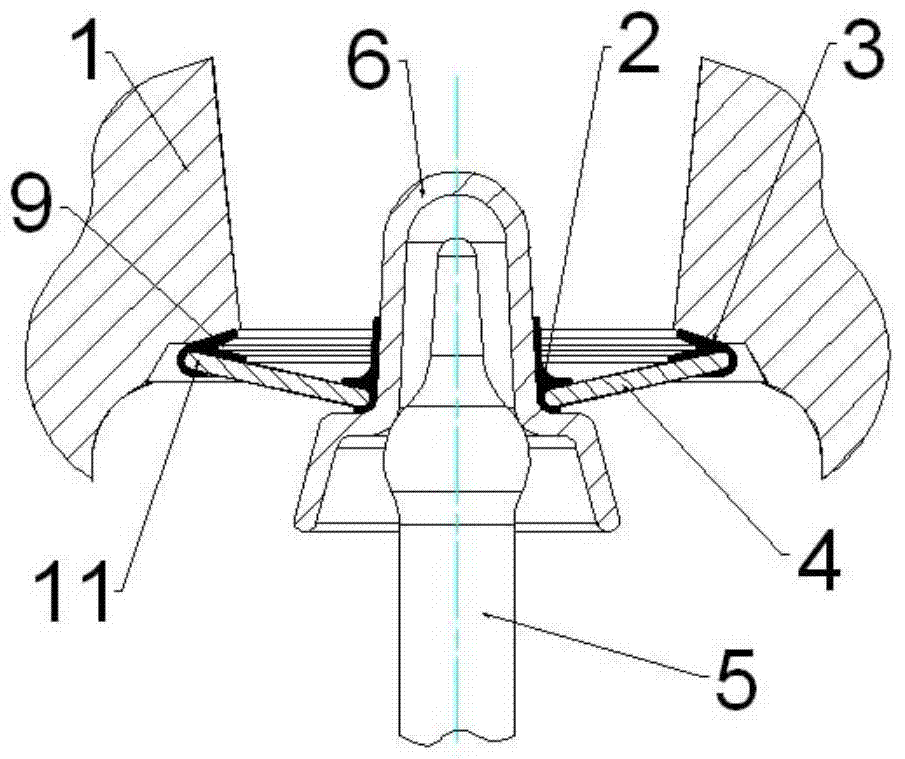

[0064] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 As shown, the elastic sealing automatic sprinkler head includes a body 1, an inner sealing ring 2, an outer sealing ring 3, an elastic gasket 4, a temperature sensing element 5 and a temperature sensing element 25, a ball seat 6, an adjusting screw 7, and a splash plate 8 , may also include a ring support 23 or a column support 24. Among them, the inner seal ring 2 is fixedly fitted between the elastic gasket 4 and the ball seat 6, and is basically combined with them, and the diameter of the conical or cylindrical through hole of the inner seal ring 2 is slightly smaller than that of the ball seat The outer diameter of the protruding section of 6, so that the inner sealing ring 2 can tightly wrap the protruding section of the ball seat 6 in advance ( image 3 , Figure 4 , Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com