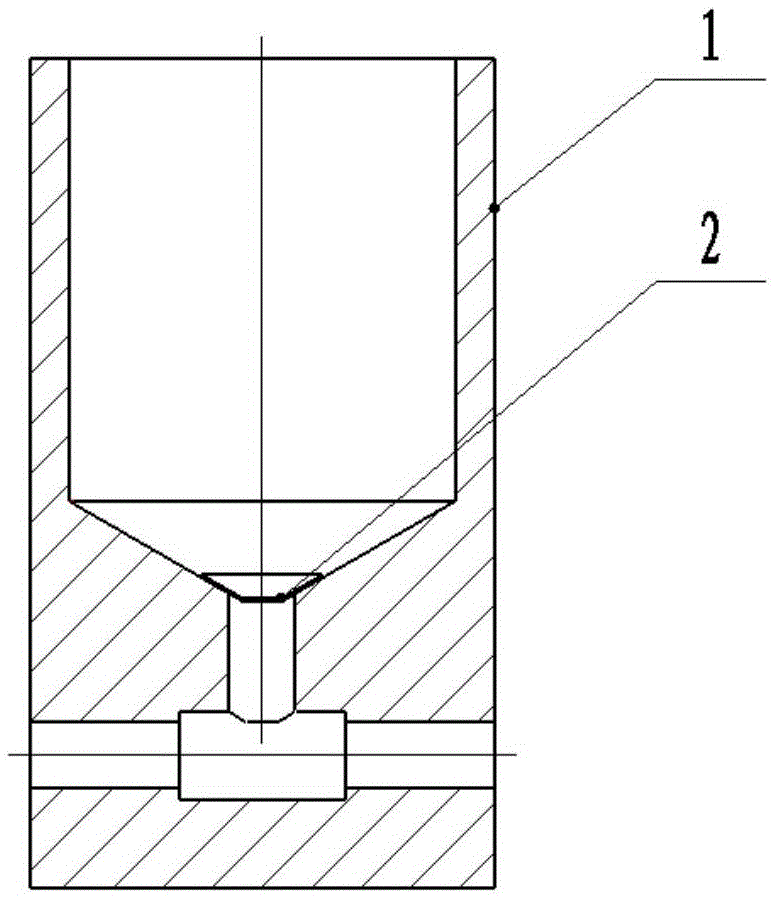

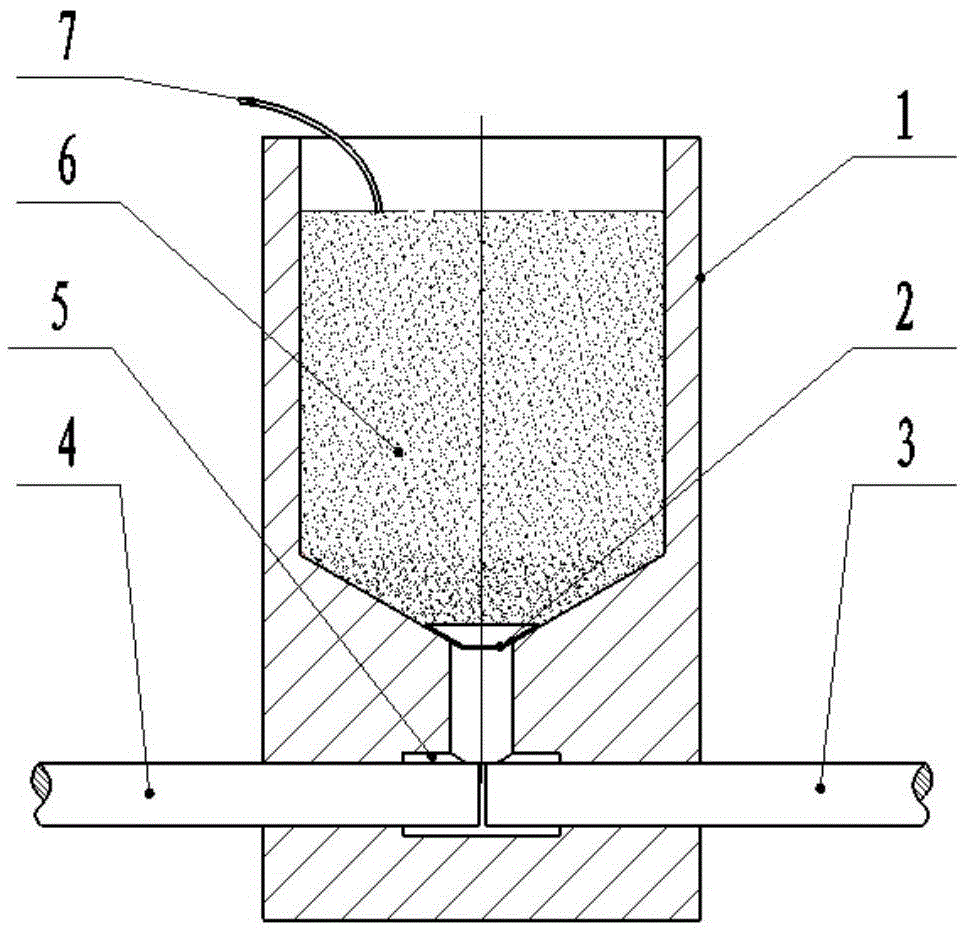

An iron-based electroless welding device

A welding device and iron-based technology, which is applied in the field and in the field of no electricity environment, can solve the problems of complex operation procedures, inconvenient operation, and high cost, and achieve the effect of low cost, less operation links, and short waiting period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

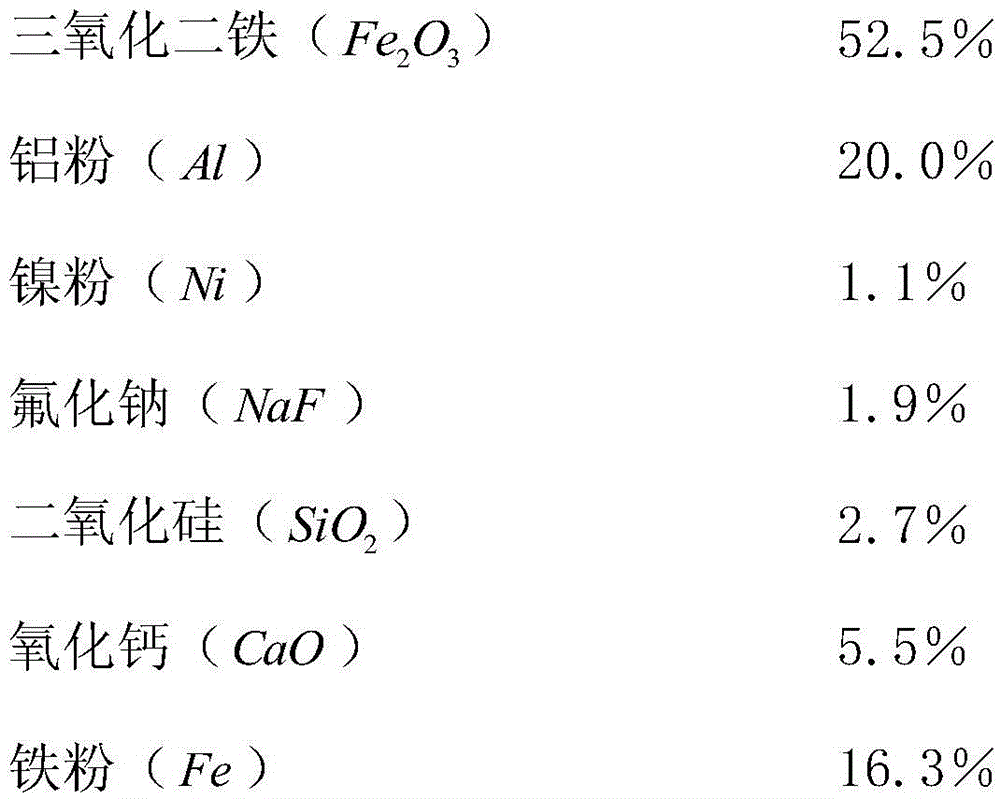

[0021] An electric-free welding flux for iron-based lightning protection and grounding devices, the components and their weight percentages are:

[0022]

Embodiment 2

[0024] An electric-free welding flux for iron-based lightning protection and grounding device, components and weight percentages thereof:

[0025]

[0026]

Embodiment 3

[0028] An electric-free welding flux for iron-based lightning protection and grounding devices, the components and their weight percentages are:

[0029]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com