Rotary electrode electric-fusion welding automatic back gouging device

A rotating electrode, automatic cleaning technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., to achieve the effect of easy operation, good root cleaning surface quality, and root cleaning quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

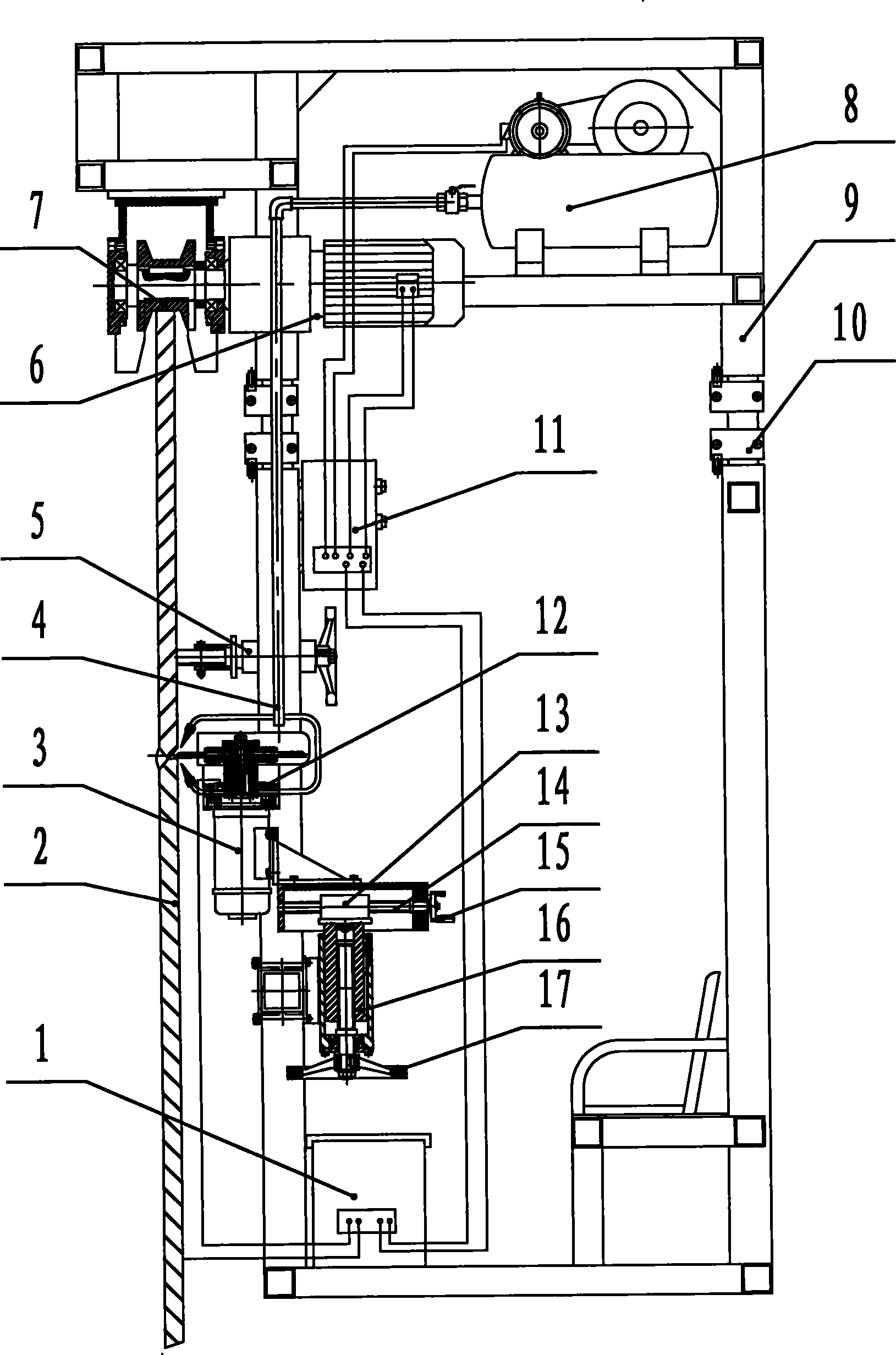

[0024] Such as figure 1 As shown, this embodiment is mainly used for cleaning the welding joints of large storage tanks. This embodiment includes a vertical frame with a frame structure. A traveling mechanism 7 that can be displaced along the top surface of the workpiece to be welded is provided on the top of the frame. The distance between the balance wheel mechanism 5 is used to adjust the distance between the frame and the workpiece, and the support frame moves smoothly; a root cleaning machine 12 is installed on the frame below the balance wheel mechanism 5; The adjusting mechanism that adjusts slide plate 16 and lateral feed slide plate 13 is installed on the drive motor 3 on the frame (wherein the axis of longitudinal adjustment slide plate 16 is parallel to the vertical bar that constitutes frame, and is fixedly connected with frame by connecting piece , the transverse feed slide plate 13 is installed on the end of the longitudinal adjustment slide plate 16, and the ax...

Embodiment 2

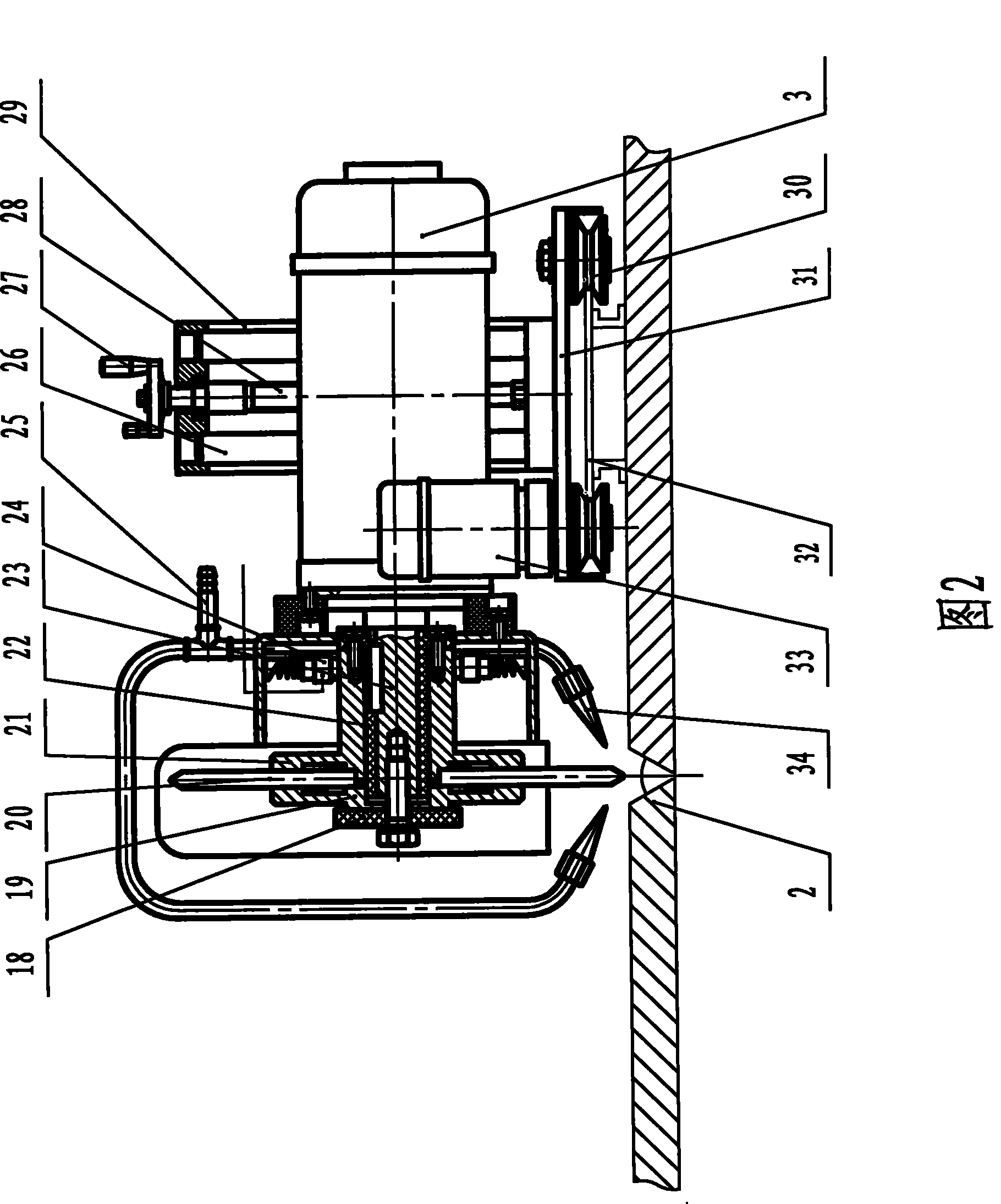

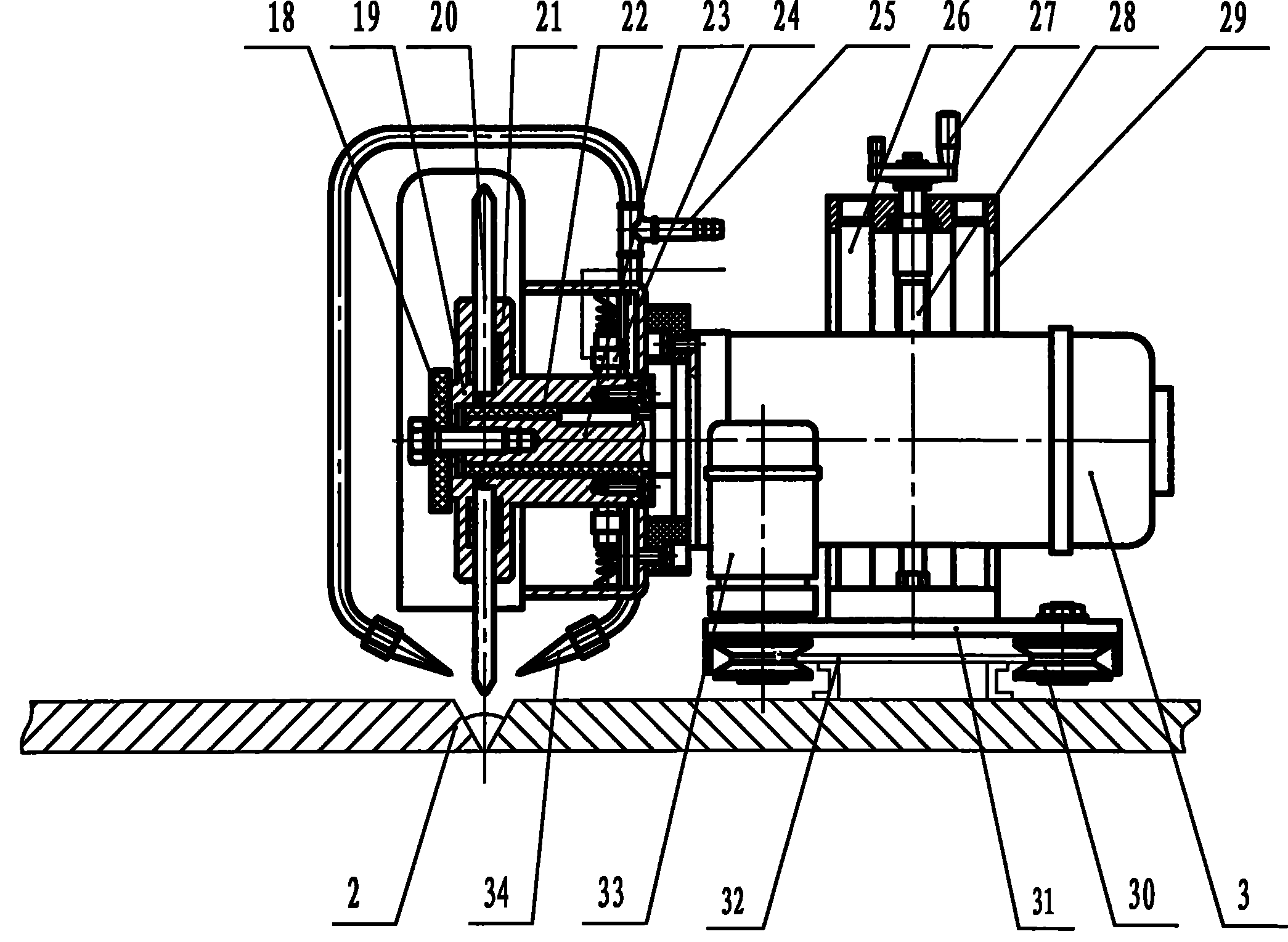

[0030] Such as figure 2 As shown, this embodiment is mainly used for cleaning the roots of welded joints of pipelines and containers, and the structure of the root cleaning machine 12 in this embodiment is the same as that of Embodiment 1. The difference between the two embodiments is that: the drive motor 3 of the root cleaner 12 is installed on the frame 31 through an adjustment mechanism composed of a transverse feed slide 29; wherein, the frame 31 is a plate structure, and The frame 31 is provided with a traveling mechanism that is formed by a sheave 30 driven by a motor 33 that is matched with the rail frame 32, and the horizontal feed slide plate 29 is installed on the frame with its axis perpendicular to the plane of the frame 31. The driving motor 3 of the root clearing machine is installed on the transverse feed slide plate 29 with its axis perpendicular to the transverse feed slide plate 29 axis. Bar 28 drives the scheme of root clearing machine 12 lateral feeds. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com