A method for manufacturing a high-temperature superconducting tape inner sealing joint

A technology of high temperature superconducting strip material and production method, which is applied in welding equipment, manufacturing tools, metal processing equipment and other directions, can solve the problems of thickness difference, uneven surface, low joint strength, etc., and achieves increased selection range, smooth appearance, The effect of uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1, a method for manufacturing a high-temperature superconducting tape inner sealing joint, the specific implementation steps are as follows:

[0025] 1. Turn on the switch 8 of the constant temperature heating platform (model 6K-2020), set the constant temperature to 230°C, and start heating. The temperature fluctuation is ±1°C.

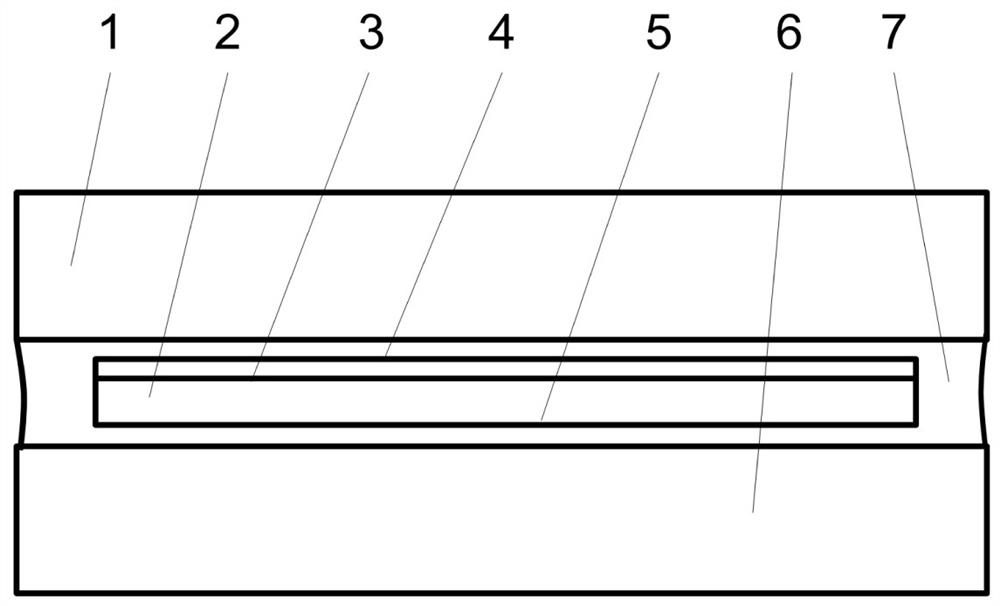

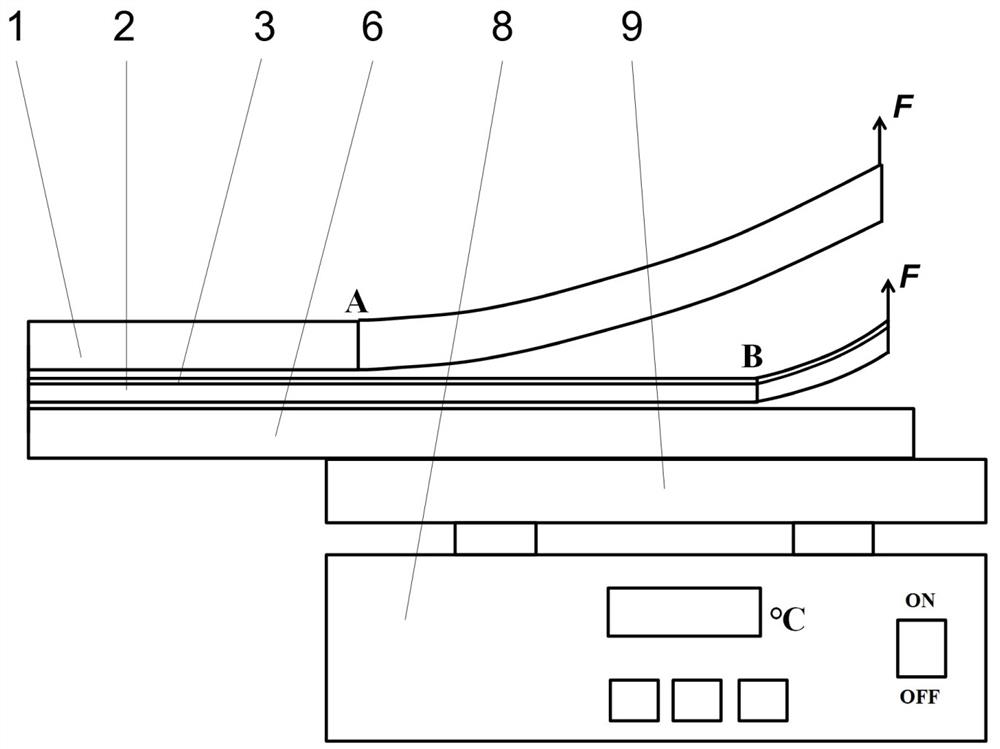

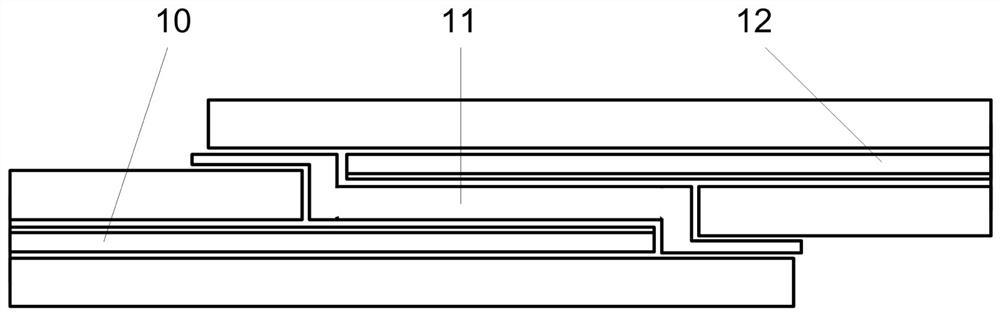

[0026] 2. 2G-HTS strip structure with sandwich structure such as figure 1 As shown, there is a superconducting core tape 2 covered with a superconducting layer 3 in the middle, an encapsulation layer A1 on the superconducting surface side 4, an encapsulation layer B6 on the base tape surface side 5, and an encapsulation solder 7 beside the superconducting core tape 2. When the temperature of the heating plate 9 of the constant temperature heating platform 8 is 230 ° C and stabilized, one end of the 2G-HTS strip A10 with a sandwich structure is placed on the heating plate 9, as figure 2 As shown, the encapsulation layer A1 on the s...

Embodiment 2

[0032] In Embodiment 2, the solder sheet 11 is made of Sn-Pb-Ag alloy (melting point 179° C.), and the rest are the same as in Embodiment 1.

Embodiment 3

[0033] In Embodiment 3, the solder sheet 11 is made of Sn-Bi alloy (melting point 139° C.), and the rest are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com