Portable manual positioner

A positioner, portable technology, applied in the field of positioner, can solve the problems of unsatisfactory welding position, welding torch swing, poor welding angle of welding torch, etc., and achieve the effect of meeting welding technical requirements, ensuring welding quality and convenient welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

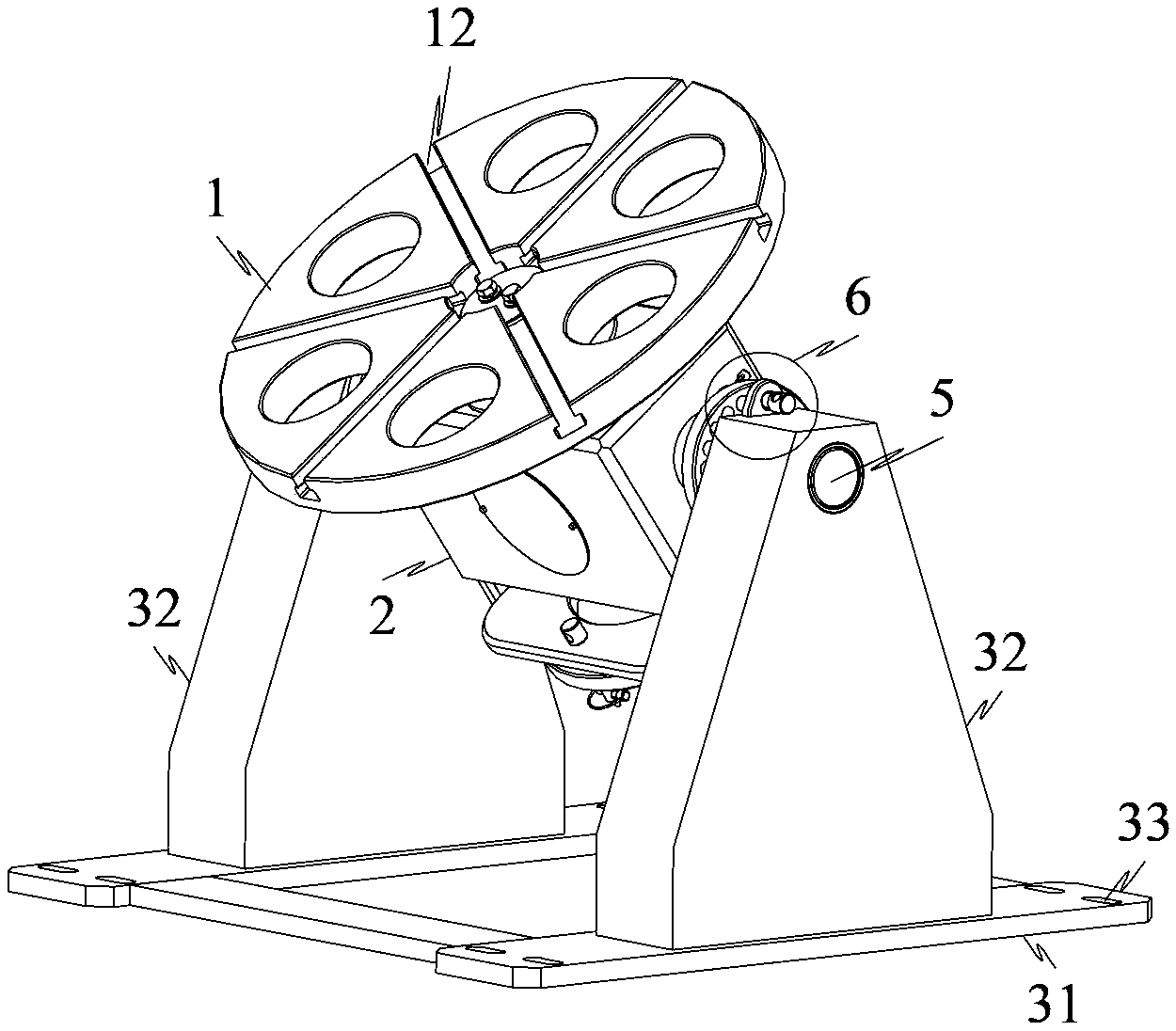

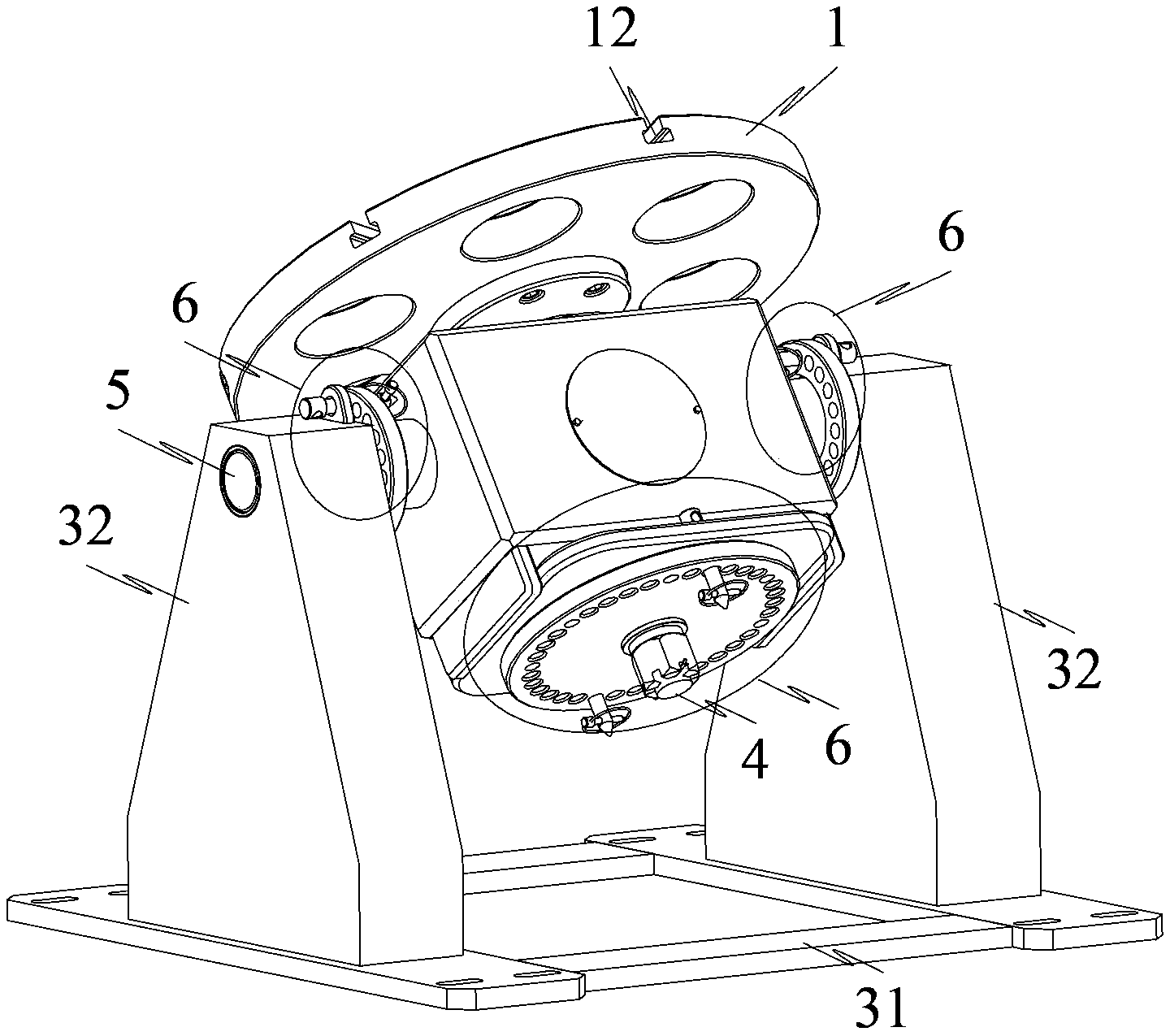

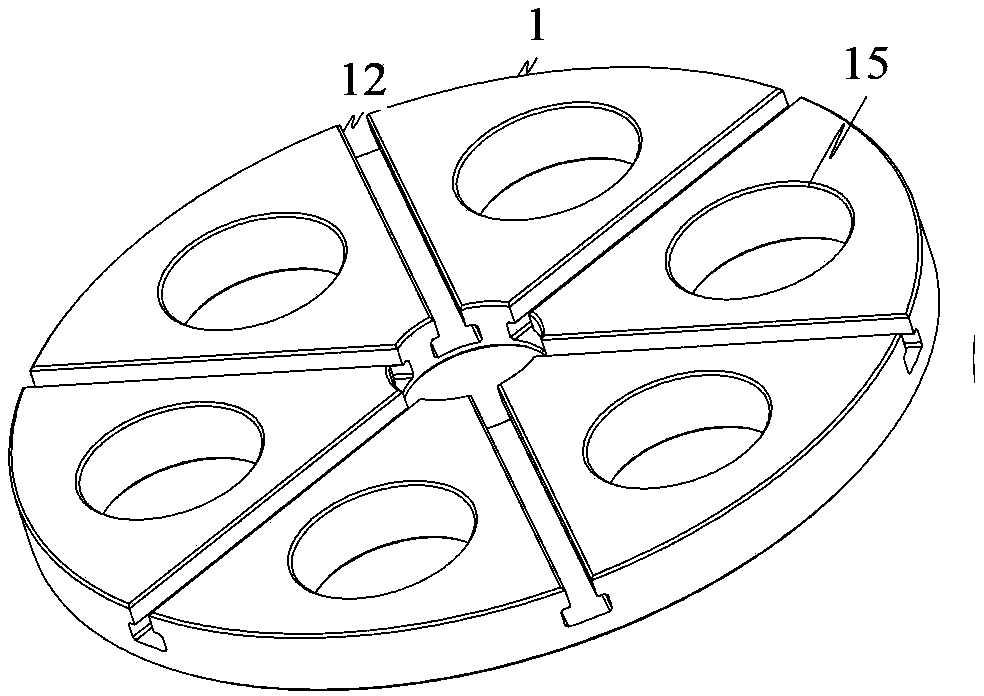

[0018] Such as Figure 1-4 As shown, the portable manual positioner provided by the present invention has a base, an axle box and a turntable; Center hole 11, such as Figure 4 As shown, at least three radial T-shaped slots 12 for installing fixtures are evenly distributed on one end surface of the disc body 1; The body 1 is rotationally connected, and the two ends of the box body 2 are respectively provided with a horizontal axis 5 whose center line is perpendicular to the center line of the vertical axis 4; A support 32 that can provide support for the horizontal shaft 5; both ends of the horizontal shaft 5 are rotationally connected to the support 32; between the vertical shaft 4 and the box body 2 and between the horizontal shaft 5 and the support 32 are provided with locking Positioning device 6 for angle of rotation. The positioning device 6 here can be any structure that limits the relative rotation of two parts, such as a dial shaft can be set on the rotating part (...

Embodiment 2

[0022] Such as Figure 5 , Figure 6 As shown, as a preferred implementation of the above-mentioned embodiment, the positioning device 6 specifically includes a positioning disc 61, a positioning pin 62 and a locking pin 63; the positioning disc 61 has a center for passing on the vertical shaft 4 or the horizontal shaft 5 Hole 611 and a plurality of positioning holes 612 that are evenly distributed in this center hole 611 a week; On the support 32 and on the casing 2, a fixed plate 64 is provided, and the fixed plate 64 is provided with any positioning hole on the positioning plate 61. 612 centerline coincident pin hole 65, positioning pin 62 is set in this pin hole 65 and in the positioning hole 612 coincident with this pin hole 65 centerline; Positioning pin 62 one end is provided with the step 621 that is used for anti-off, and the other end is provided with There is a locking hole 622 , and the locking bolt 63 passes through the locking hole 622 . The locking bolt 63 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com