Backstop device of wood sawing machine

A wood sawing machine and anti-reverse technology, which is applied to circular saws, sawing equipment, wood processing appliances, etc., can solve the problems of losing anti-reverse effect, poor anti-reverse effect, unable to effectively prevent the reverse ejection of wood, etc. Personal injury accident, reliable anti-reverse effect, and the effect of preventing reverse ejection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

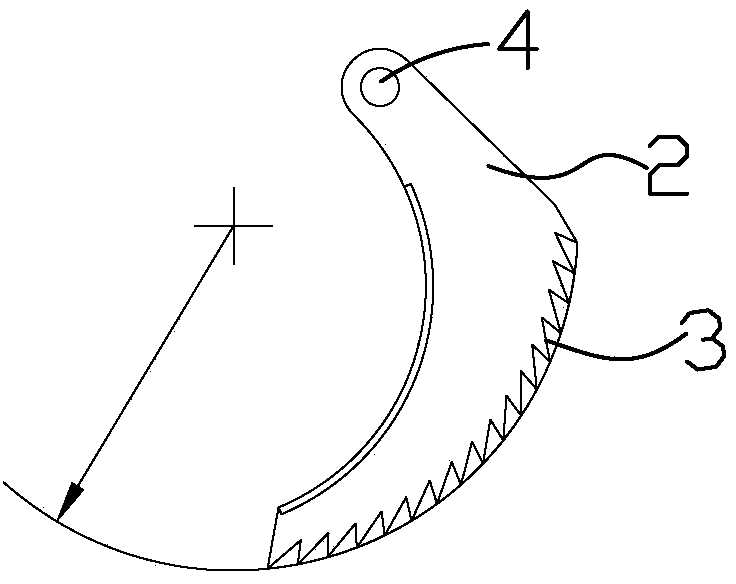

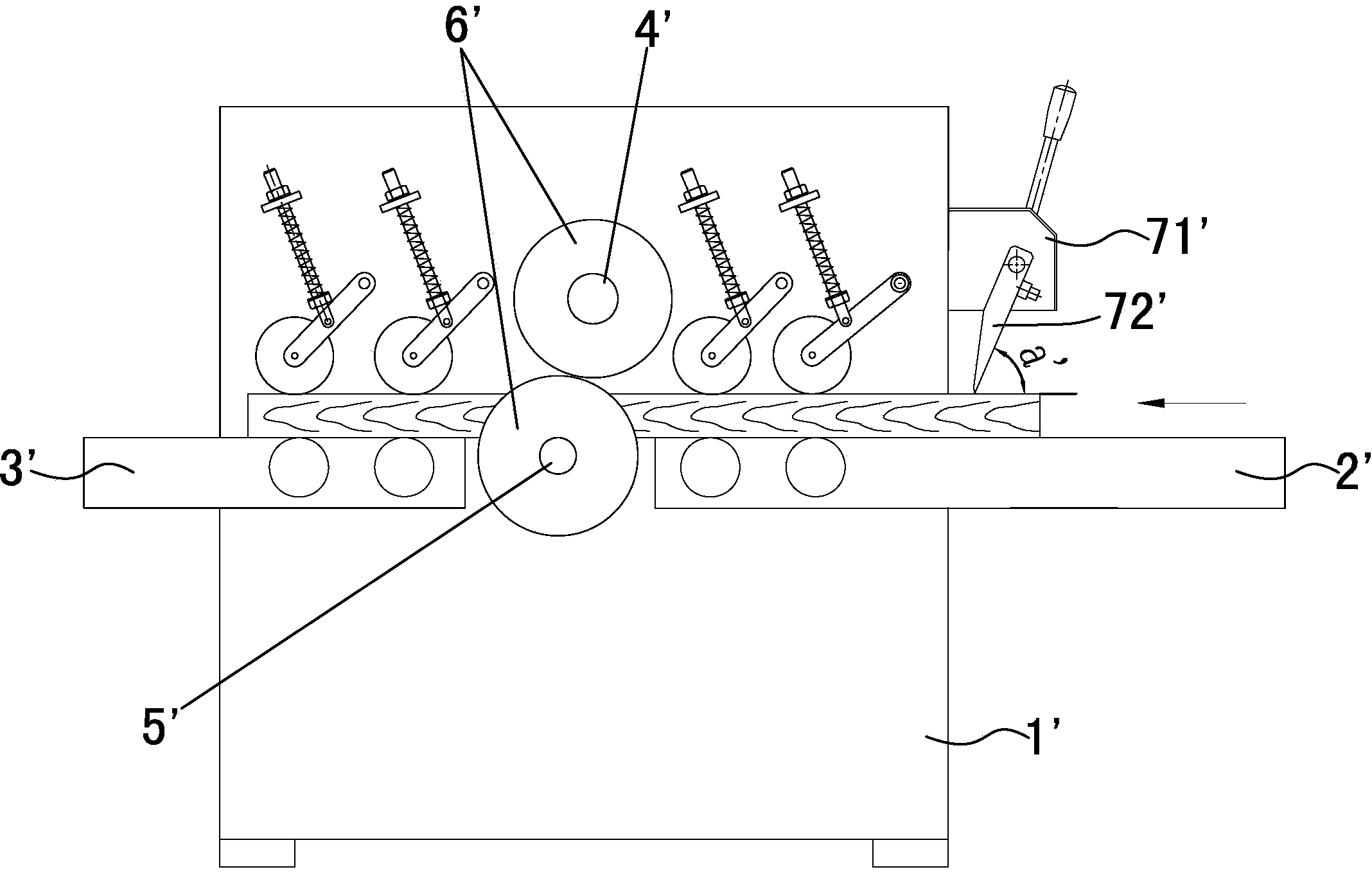

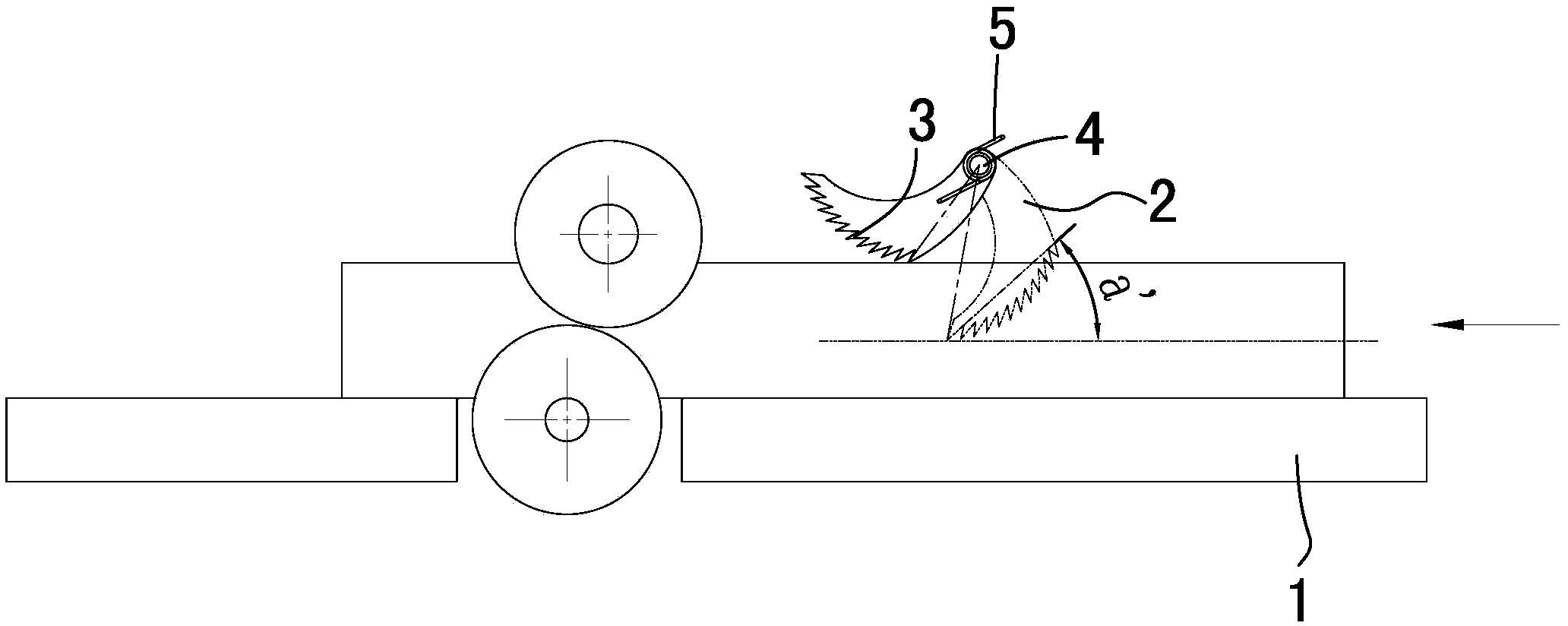

[0012] refer to figure 2 and image 3 , This embodiment discloses a backstop device for a wood sawing machine, which includes a backstop seat installed above the wood input mechanism 1 on the wood saw machine chassis and a backstop seat that can swing up and down through the rotating shaft 4 The anti-reverse claw 2 on the body, the lower surface of the non-reverse claw 2 is an arc surface, and the anti-reverse saw teeth 3 are uniformly distributed on the arc surface, such as image 3 As shown, the arc center of the arc surface deviates from the axis of the rotating shaft.

[0013] A torsion spring 5 is provided between the rotating shaft 4 and the non-reverse pawl 2 . The torsion spring makes the non-reverse pawl after being lifted by the wood have a downward and backward torsion to resist the wood, further preventing the reverse ejection of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com