Hopper

A hopper and bucket body technology, which is applied in the field of packaging machinery, can solve the problems of high impact force, low work reliability, and waste of materials, and achieve the effects of improving reliability, reducing labor intensity, and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

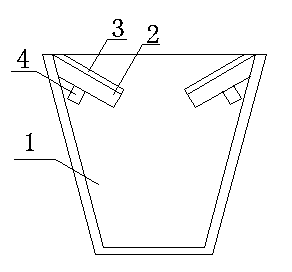

[0009] Such as figure 1 It is a structural schematic diagram of the present invention, a hopper, including a bucket body 1, a blanking plate 2, a baffle plate 3 and a vibrator 4, a blanking plate 2 is provided on both sides of the upper end of the bucket body 1, and a blanking plate 2 is provided on both sides of the blanking plate 2. A vibrator 4 is arranged at the bottom of the baffle plate 3 and the blanking plate 2 .

[0010] When in use, there are blanking plates 2 on both sides of the upper end of the bucket body 1, and baffles 3 on both sides of the blanking plate 2, which can prevent materials from falling outside the hopper and causing waste. The bottom of the blanking plate 2 is equipped with a vibrator 4. Start the vibrator 4 so that the material can fall at a constant speed. This kind of hopper has a simple, compact and reasonable structure, convenient and quick assembly, and reliable connection. The material is not easy to slide to the outside of the hopper when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com