Portable DC electric hoist

A direct current and moving hoist technology, applied in portable lifting devices, hoisting devices, spring mechanisms, etc., can solve the problems of low mechanical efficiency, bulky structure, inconvenient use of lifting equipment outdoors or at home, etc., and achieve safety performance Better, safe and reliable hoisting, avoiding the effect of sudden load drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

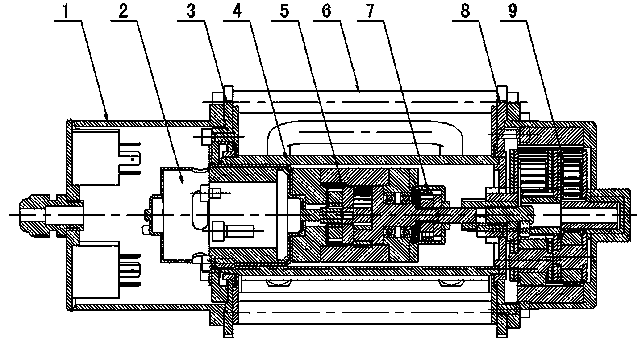

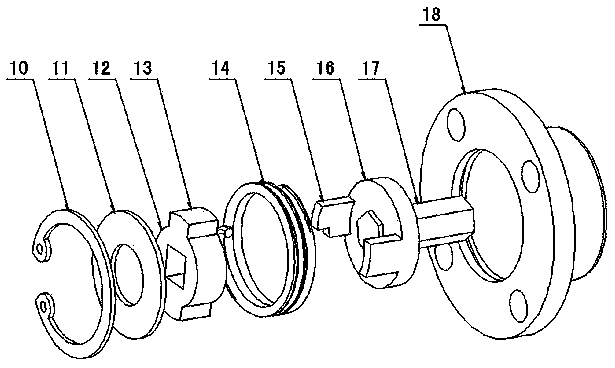

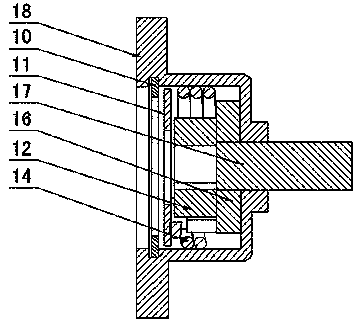

[0014] Figure 1 to Figure 5 As shown, the invention creates a specific embodiment of a portable DC electric hoist, including a controller 1, a DC motor 2, a left end plate 3, a rope drum 4, a first reducer 5, a right end plate 8, and a second reducer 9 , the left and right end plates 3, 8 are fixedly connected as a whole through the connecting rod 6, the rope drum 4 is rotatably arranged on the left and right end plates 3, 8, and the DC motor 2 and the first reducer 5 are fixed and installed on the left end plate 3 and placed in the rope drum 4, the second speed reducer 9 is fixed on the right end plate 8, a transmission brake device 7 is provided between the first speed reducer 5 and the second speed reducer 9, the device includes a Moving jacket 18, brake coil spring 14, input block 12, output block 16, brake jacket 18 is fixed on the first speed reducer 5, input block 12 and output block 16 are arranged in brake jacket 18 and are connected by gasket 11 Positioned with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com