A flour storage system for a food processing plant

A storage system and processing plant technology, applied in tank trucks, packaging, climate change adaptation, etc., can solve the problems of uneven dryness, agglomeration of flour materials, unfavorable feeding, etc., achieve good storage, improve anti-caking effect, The effect of ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

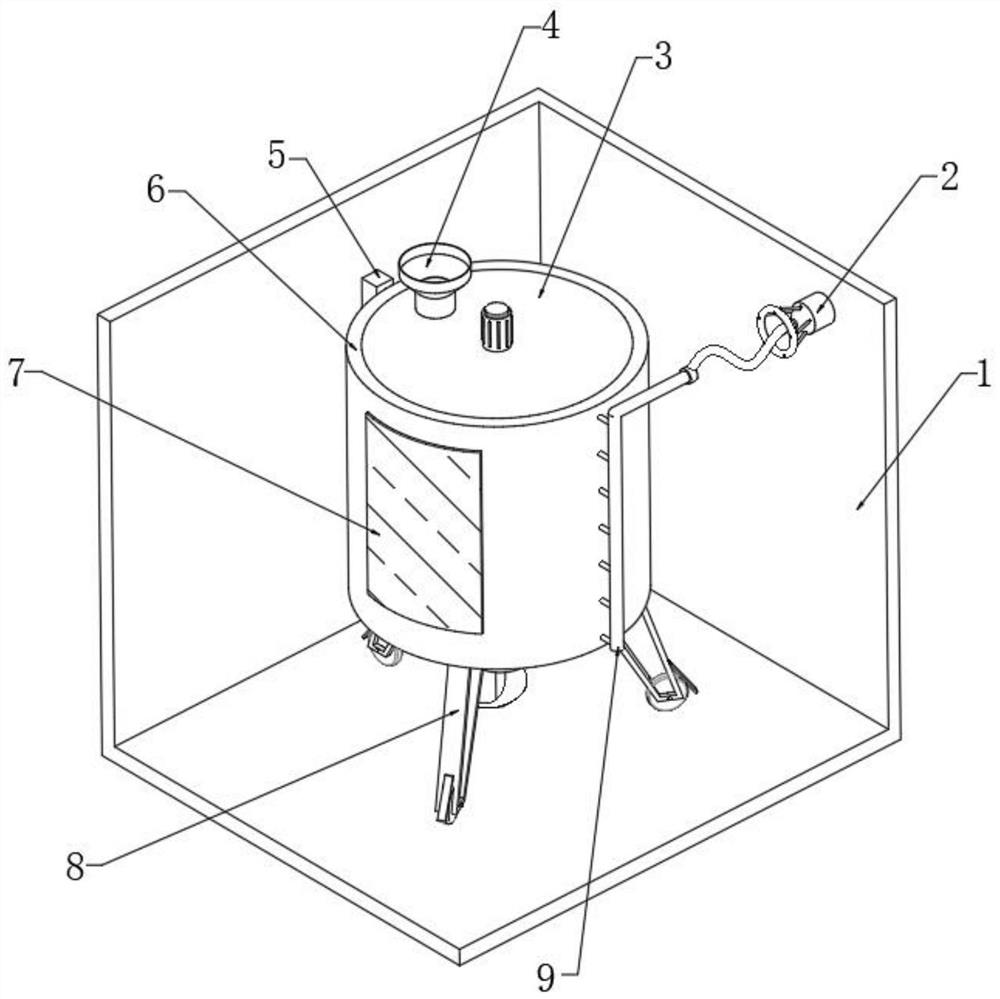

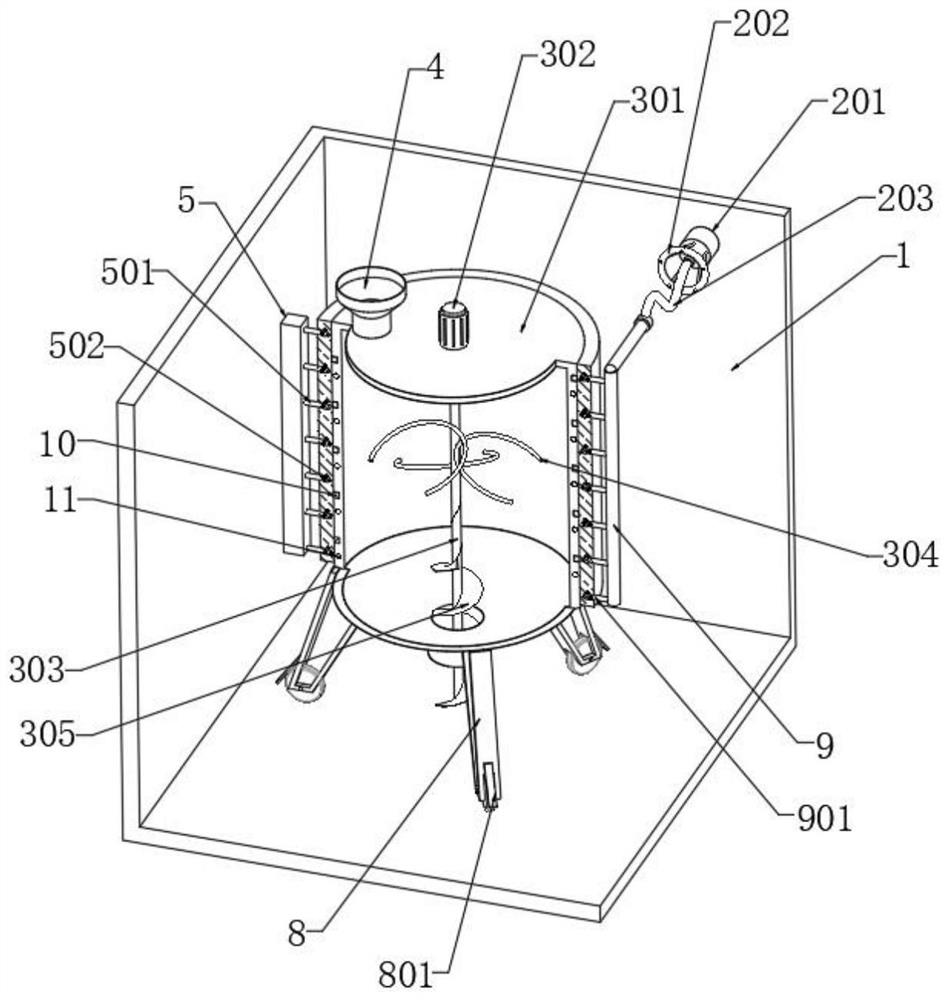

[0035] like Figure 1 to Figure 5As shown, the embodiment of the present invention provides a flour storage system for a food processing plant, including a storage room 1, a storage mechanism 3 is arranged inside the storage room 1, and an air purification mechanism 2 is arranged on one side of the storage room 1, and the storage The mechanism 3 includes a storage tank 301 arranged inside the storage room 1, and the inner wall of the storage tank 301 is provided with a spiral installation cavity, the inside of the spiral installation cavity is fixedly installed with the spiral heating wire 11, and the circumferential outer wall of the storage tank 301 is fixedly installed with an outer layer. 6, and the outer layer 6 is provided with an air-cooling component, the interior of the storage tank 301 is provided with an anti-caking component, and the anti-caking component includes a rotating rod 303 that is rotatably connected to the storage tank 301, and the top of the rotating rod...

Embodiment 2

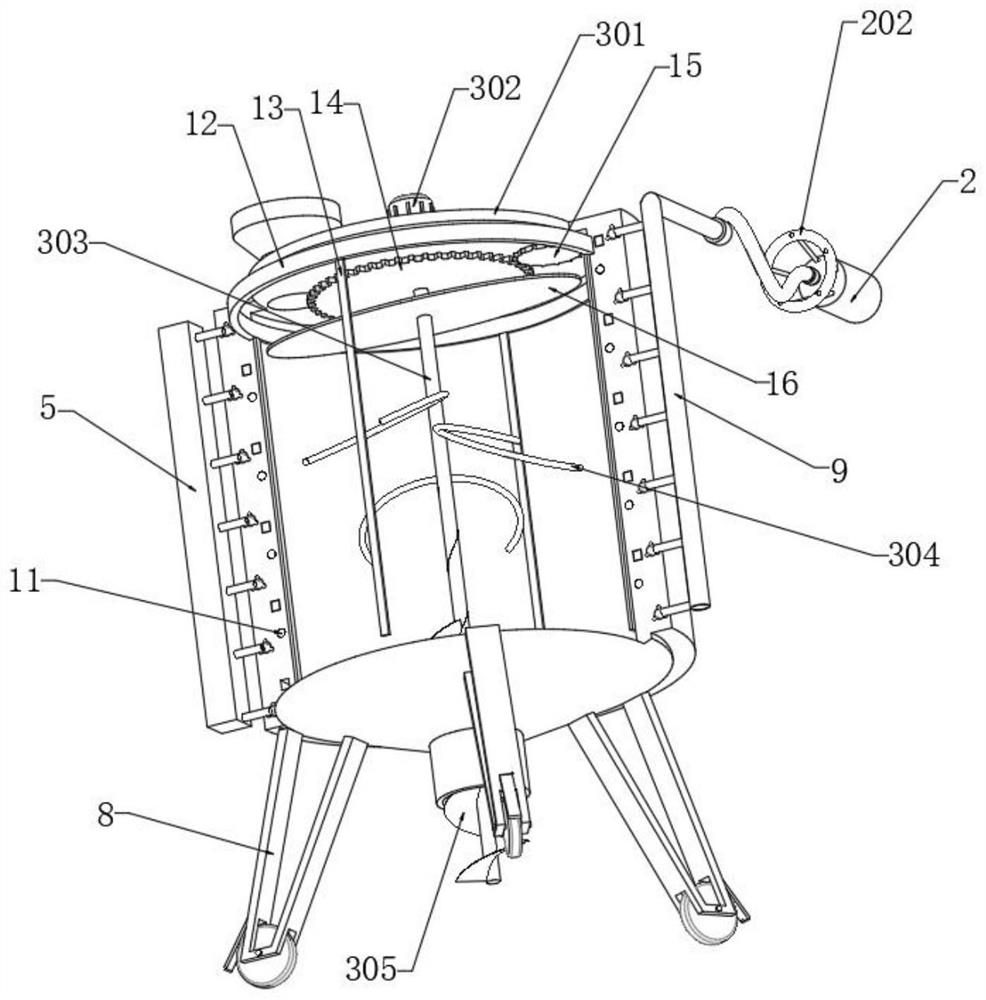

[0046] like Figures 6 to 8 As shown, the second embodiment of the present invention provides a flour storage system for a food processing factory. Compared with the first embodiment, this embodiment includes a C-shaped frame 17 fixedly installed on the top of the storage tank 301, and the C-shaped The frame 17 is fixedly connected with the servo motor 302, the two ends of the C-shaped frame 17 are fixedly installed with electric telescopic rods 18, and the ends of the extension rods of the two electric telescopic rods 18 are fixedly installed with a disk 19, and the center of the disk 19 is fixedly installed. The sleeve 20 is rotatably connected, and the sleeve 20 and the rotating rod 303 are slidably connected in the vertical direction. The two ends of the outer circumferential wall of the rotating rod 303 are provided with convex ribs, and the circumferential inner wall of the sleeve 20 is provided with convex ribs. The matching chute, the C-shaped breaking rod 304 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com