A kind of porcelain flame retardant and fireproof silicone sealant and preparation method thereof

A technology of silicone sealant and vitrification, applied in chemical instruments and methods, adhesives, other chemical processes, etc., can solve problems such as loss of fixation and sealing effects, achieve good physical and mechanical properties, convenient operation, and excellent adhesion and storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

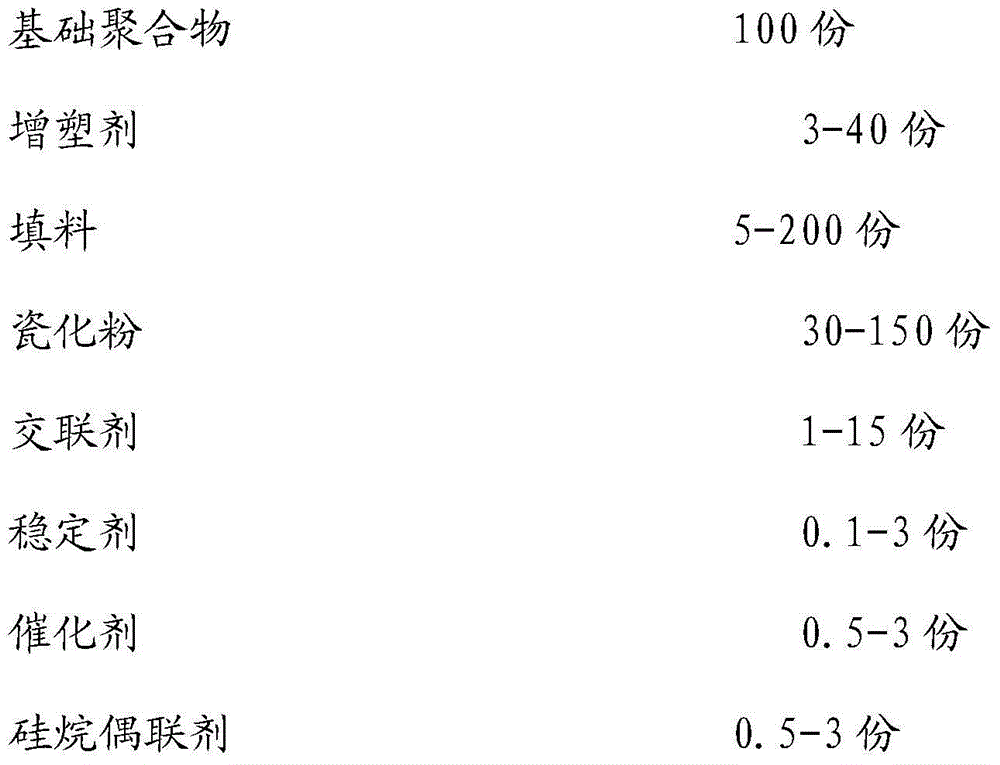

Method used

Image

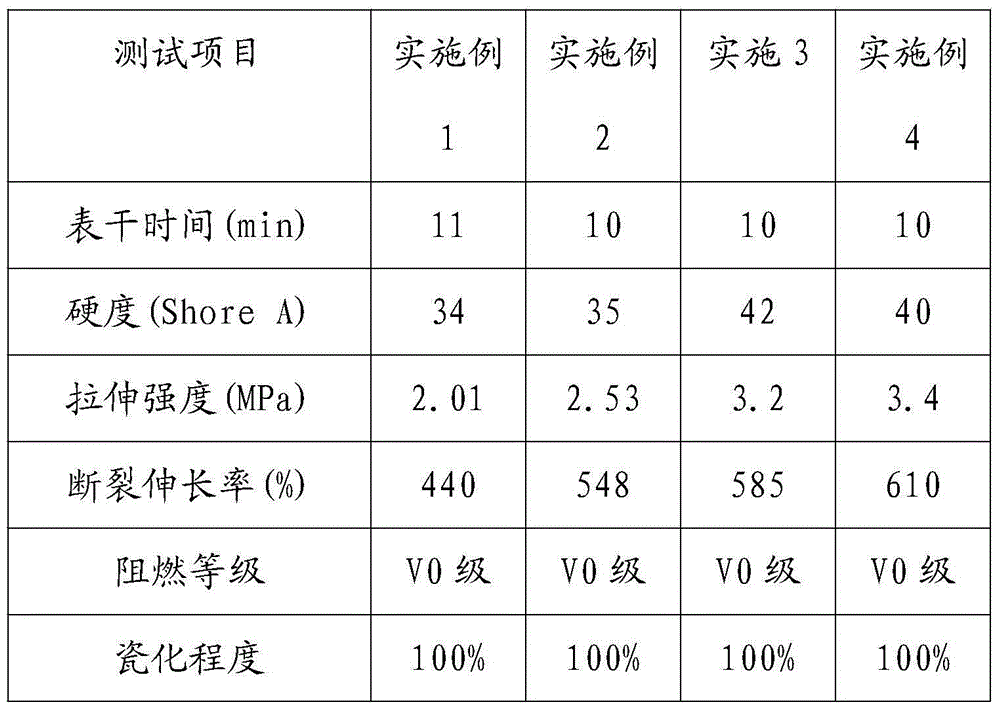

Examples

Embodiment 1

[0020] According to weight fraction, put 100 parts of trimethoxy-terminated polydimethylsiloxane with a viscosity of 20000cps, 6 parts of silicon powder, and 100 parts of aluminum oxide into the kneader. Keep the temperature at 150℃ and the vacuum Dehydrate and blend for 2h between 0.06-0.09MPa, grind twice through a mill, transfer to a high-speed dispersion stirring tank and cool to room temperature to obtain a base material. At room temperature, 6.5 parts of methyltrimethoxysilane, vinyltrimethyl 1.5 parts of oxysilane, 0.8 parts of γ-aminopropyltriethoxysilane, 0.8 parts of glycidyl ether propyltrimethoxysilane, 20 parts of methyl silicone oil are added to the high-speed dispersion stirring tank, mixed with the base material, and vacuum Keep the temperature at -0.1-0.06MPa, keep the speed at 250rpm, stir for 1h, add 0.7 parts of bis(ethyl acetoacetate) bis(isopropoxy) titanate complex, stir, keep the vacuum at -0.1- 0.06MPa, the speed is maintained at 250rpm, after stirring ...

Embodiment 2

[0022] According to weight fraction, put 100 parts of hydroxyl-terminated polydimethylsiloxane with a viscosity of 20000cps, 15 parts of fumed white carbon black, and 80 parts of silica into the kneader, keep the temperature at 150℃, and the vacuum degree at 0.06- Dehydrate and blend for 2 hours at 0.09MPa, grind twice through a mill, transfer to a high-speed dispersion stirring tank and cool to room temperature to obtain the base material. Add 8 parts of methyltrimethoxysilane at room temperature and vinyltrimethoxy Add 1 part of silane, 0.5 part of isocyanate propyltriethoxysilane, 0.6 part of β-aminoethyl-γ-aminopropyltrimethoxysilane, and 20 parts of methyl silicone oil into the high-speed dispersion stirring tank, and Base material mixing, keep the vacuum degree at -0.1-0.06MPa, keep the speed at 250rpm, stir for 1h, add 0.7 part of isopropyl titanate, stir, keep the vacuum degree at -0.1-0.06MPa, keep the speed at 250rpm, stir for 1h After discharging and filling into can...

Embodiment 3

[0024] According to weight fraction, put 100 parts of methyldimethoxy-terminated polydimethylsiloxane with a viscosity of 20000cps, nano-calcium carbonate 2, silicon powder 3, quartz powder 1 part, potassium oxide 65, barium oxide 35 parts Put it into the kneader, keep the temperature at 150℃, the vacuum degree is between 0.06-0.09MPa for dehydration and blending for 2h, grind it twice through the mill, then transfer it into the high-speed dispersion stirring tank and cool to room temperature to obtain the base material. Next, 4.5 parts of methyltrimethoxysilane, 1.5 parts of vinyltrimethoxysilane, 0.8 parts of γ-aminopropyltriethoxysilane, 0.8 parts of β-aminoethyl-γ-aminopropyltrimethoxysilane , 20 parts of alkoxy silicone oil, 10 parts of white oil, add to the high-speed dispersion stirring tank, mix with the base material, keep the vacuum degree at -0.1-0.06MPa, keep the speed at 250rpm, stir for 1h, add bis(ethyl acetoacetate) Ester) bis(isopropoxy) titanate complex 0.5 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com