Quantitative evaluation method of imbibition and oil production effects of imbibition agent

A kind of imbibition agent and imbibition technology, which is applied in the development of fluids, earthwork drilling, wellbore/well components, etc., can solve the problems of restricting the development and optimization of imbibition agents, lack of imbibition recovery rate evaluation methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

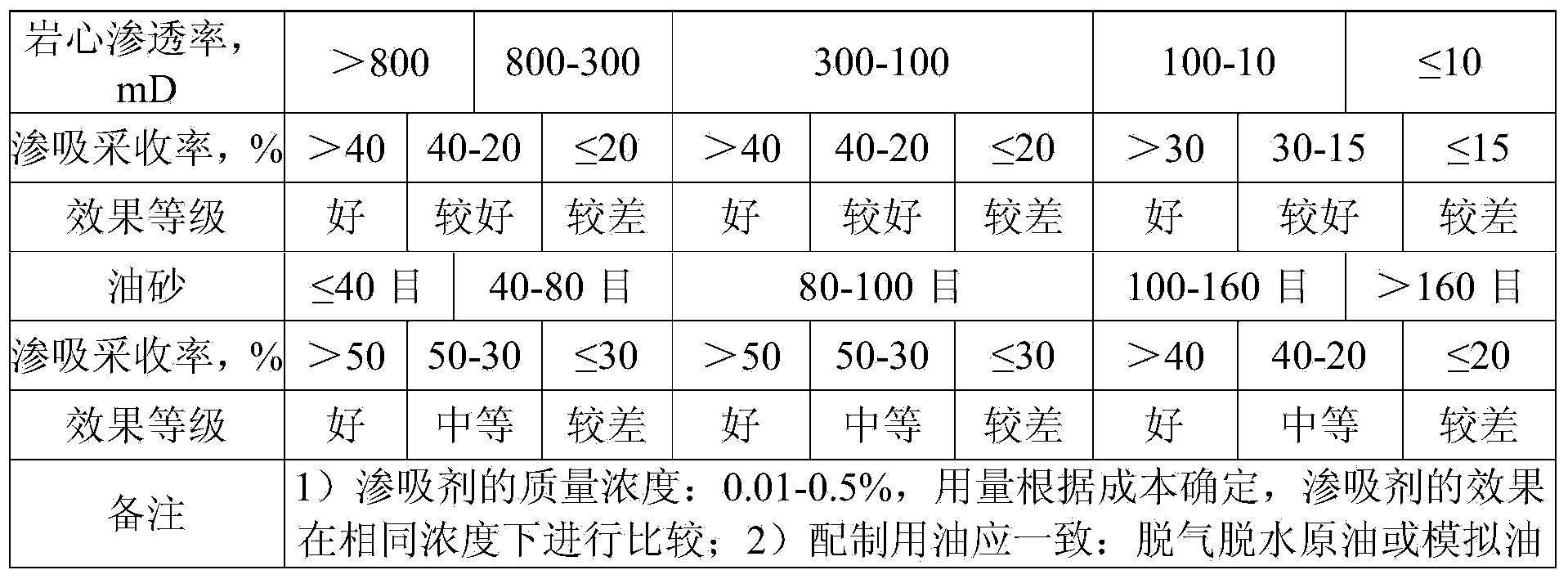

[0079] This example provides a quantitative evaluation method for the oil recovery effect of imbibition, which is the screening of imbibants in low-permeability reservoirs (permeability lower than 10mD) in the periphery of Daqing, which includes the following steps:

[0080] (1) First, mix 8 kinds of osmotic agents into the same concentration of osmotic agent solution (0.2wt%), and select aged 100-160 mesh Daqing oil sand;

[0081] (2) Use the same imbibition meter to keep warm in a 45°C thermostat to test the recovery of imbibition (according to the above-mentioned steps). The main ingredients are tridecyl dimethyl betaine ammonium salt, pentadecyl dimethyl betaine ammonium salt and dodecyl dimethyl betaine ammonium salt, these three and lauryl betaine (as Contrast) are all produced by Nantong Kaihua Chemical Co., Ltd.; the main component of A1284 is OP-6, which is alkylphenol polyoxyethylene (6) ether, produced by Xingtai Lanxing Auxiliary Factory.

[0082] (3) Compare the ...

Embodiment 2

[0087] This embodiment provides a quantitative evaluation method for the imbibition effect of the imbibition agent, which is aimed at the evaluation method of the imbibition effect of the imbibition agent in medium-high permeability reservoirs in Daqing, including the following steps:

[0088] (1) Two prepared Daqing oil sands (40-80 mesh and 80-100 mesh, crude oil density 0.8450g / cm 3 ), aging for 96 hours at 45°C;

[0089] (2) Select betaine osmotic agent TCJ18 (TCJ18 refers to octadecyl dimethyl betaine ammonium salt, produced by Nantong Kaihua Chemical Co., Ltd.), and carry out 24-hour imbibition recovery on this osmotic agent Efficiency test, the results are shown in Table 4. The imbibant solution was prepared with Daqing simulated water with a salinity of 5228mg / L), and the imbibition recovery values of the prepared imbibrant solutions with different concentrations were measured;

[0090] (3) According to the evaluation content in Table 2, compare the above-mentioned ...

Embodiment 3

[0095] This embodiment provides a quantitative evaluation method for the imbibition effect of the imbibition agent, which is an evaluation method for the imbibition effect of the imbibition agent in Daqing high-permeability reservoirs, including the following steps:

[0096] (1) Select 40-80 mesh oil sands, use the imbibant JBX-1 (the main component is sodium polyacrylate, produced by Shandong Taihe Water Treatment Co., Ltd.) Carry out imbibition experiment at reservoir temperature to measure the value of imbibition recovery;

[0097] (2) The test results of 24-hour imbibition recovery are shown in Table 5;

[0098] (3) Compare the test results with the evaluation content in Table 2 to determine the effect level.

[0099] table 5

[0100]

[0101] It can be seen from the contents of Table 5 that different concentrations of imbibant solutions have different effects on the same oil sand, and there is an optimal concentration for the same oil sand. The concentration of the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap