A ball joint structure for a passenger car

A joint structure and passenger car technology, applied in the direction of elastic couplings, mechanical equipment, couplings, etc., can solve the problems of poor softness and stability of ball joints, large deformation, etc., to improve softness and stability, reduce weight, The effect of increasing the contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

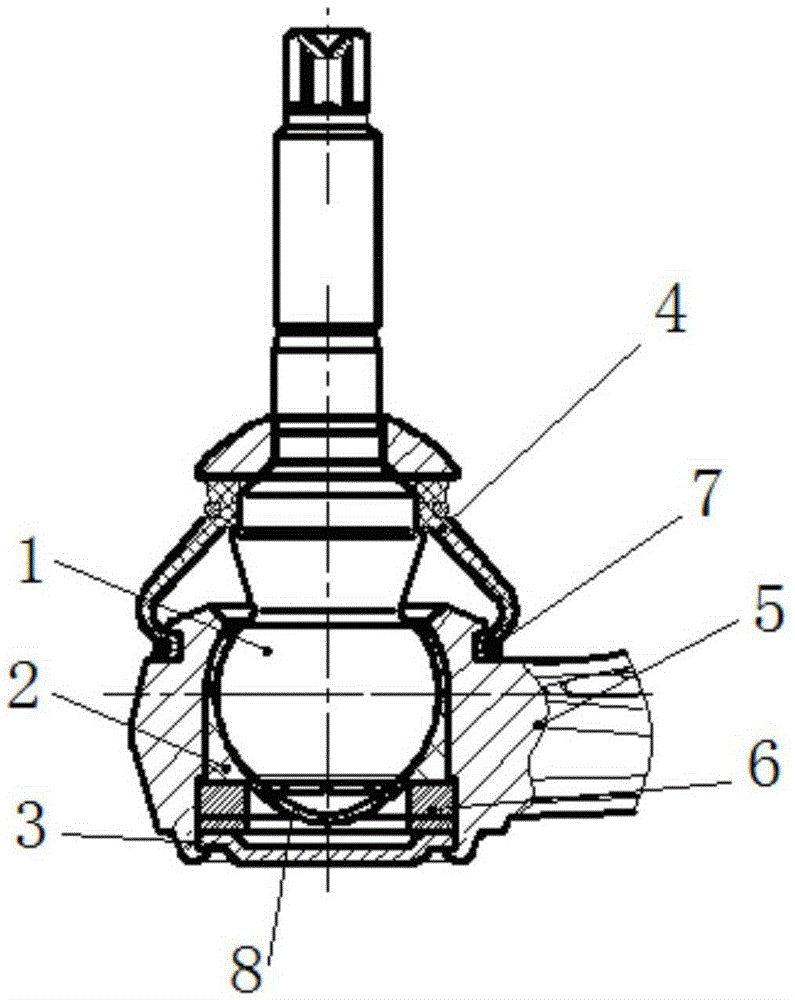

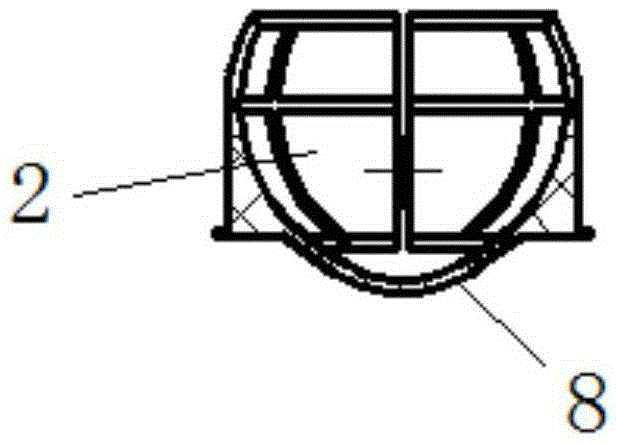

[0012] Such as Figure 1 ~ Figure 2 A ball joint structure for a passenger car is shown, including a ball pin 1, a ball seat 2, a rear cover 3, a dust cover 4, a joint 5, and a washer 6, and the washer 6 is arranged under the ball seat 2, and the joint 5 Socketed outside the ball seat 2 and the washer 6, the joint 5 is equipped with a back cover 3 covering the washer 6, the ball pin 1 includes a vertebral body, a connecting rod end connected to the two ends of the vertebral body, and a ball end surface, and the ball pin 1 The ball end surface of the ball is connected in the ball seat 2, the dust cover 4 is clamped on the joint 5 through the collar 7, the ball seat 2 is a split structure composed of two hemispherical seats, and the two hemispherical seats are connected by an arc Arm 8 is connected.

[0013] The dust cover 4 is sleeved on the vertebral body of the ball pin 1 . The structure of the ball seat adopts the technology of split left and right, the center of the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com