Method for reserving large-area refractory castable construction expansion gaps

A technology of refractory castables and expansion joints, which is applied in the field of setting expansion joints in industrial furnace construction. It can solve the problems that the expansion joints are difficult to leave evenly, straightly, and the position is correct and the size meets the design requirements. It achieves reasonable design and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

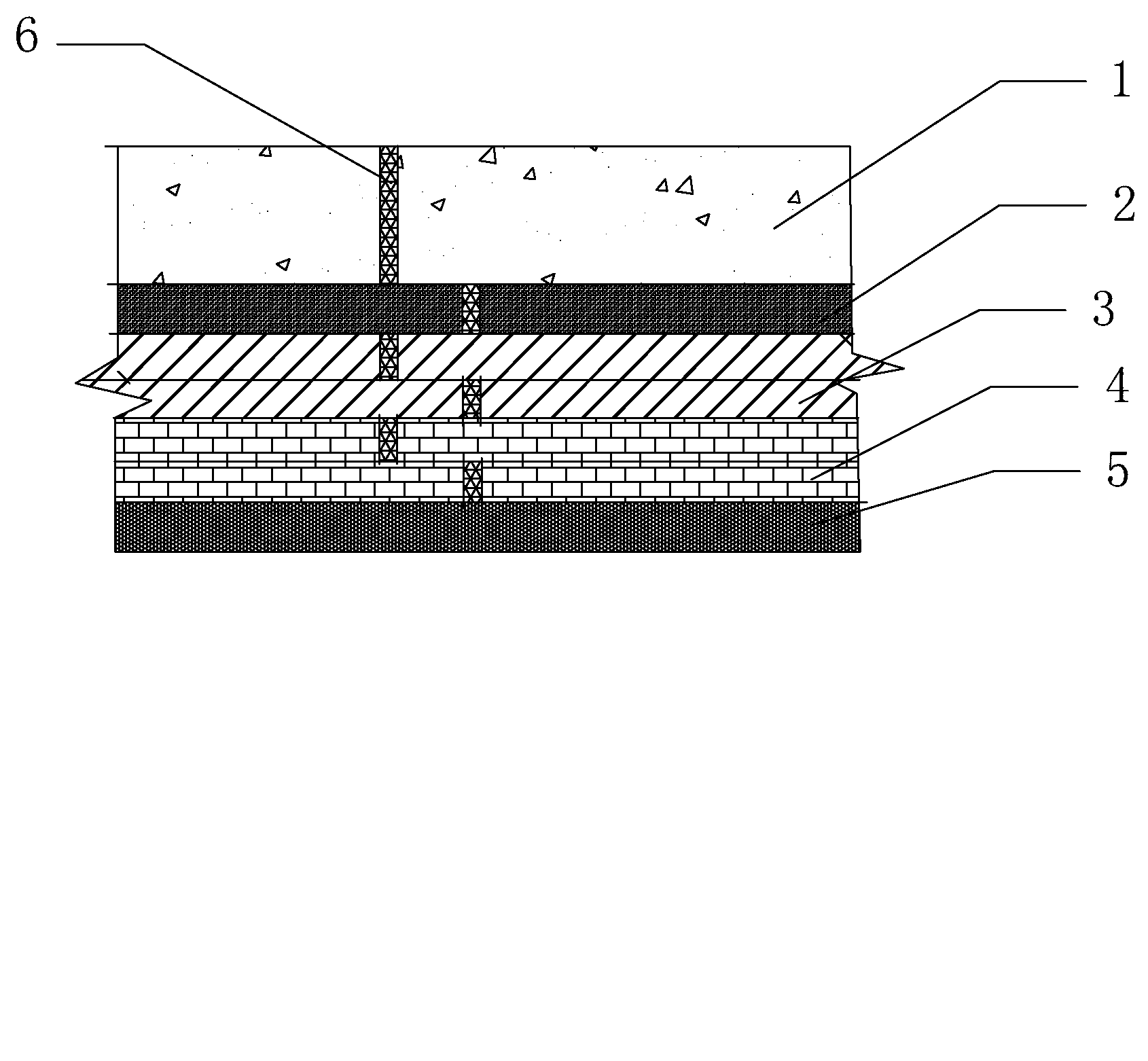

[0023] figure 1 It is a structural schematic diagram of the bottom refractory material of the annular furnace according to the embodiment of the present invention. The heating temperature range of the high-temperature ring furnace is 1250-1280 ℃, the average furnace diameter is 48000mm, the furnace bottom and roof are 5400mm wide, and the furnace wall height is 2000mm. The object is a ceramic fiber blanket.

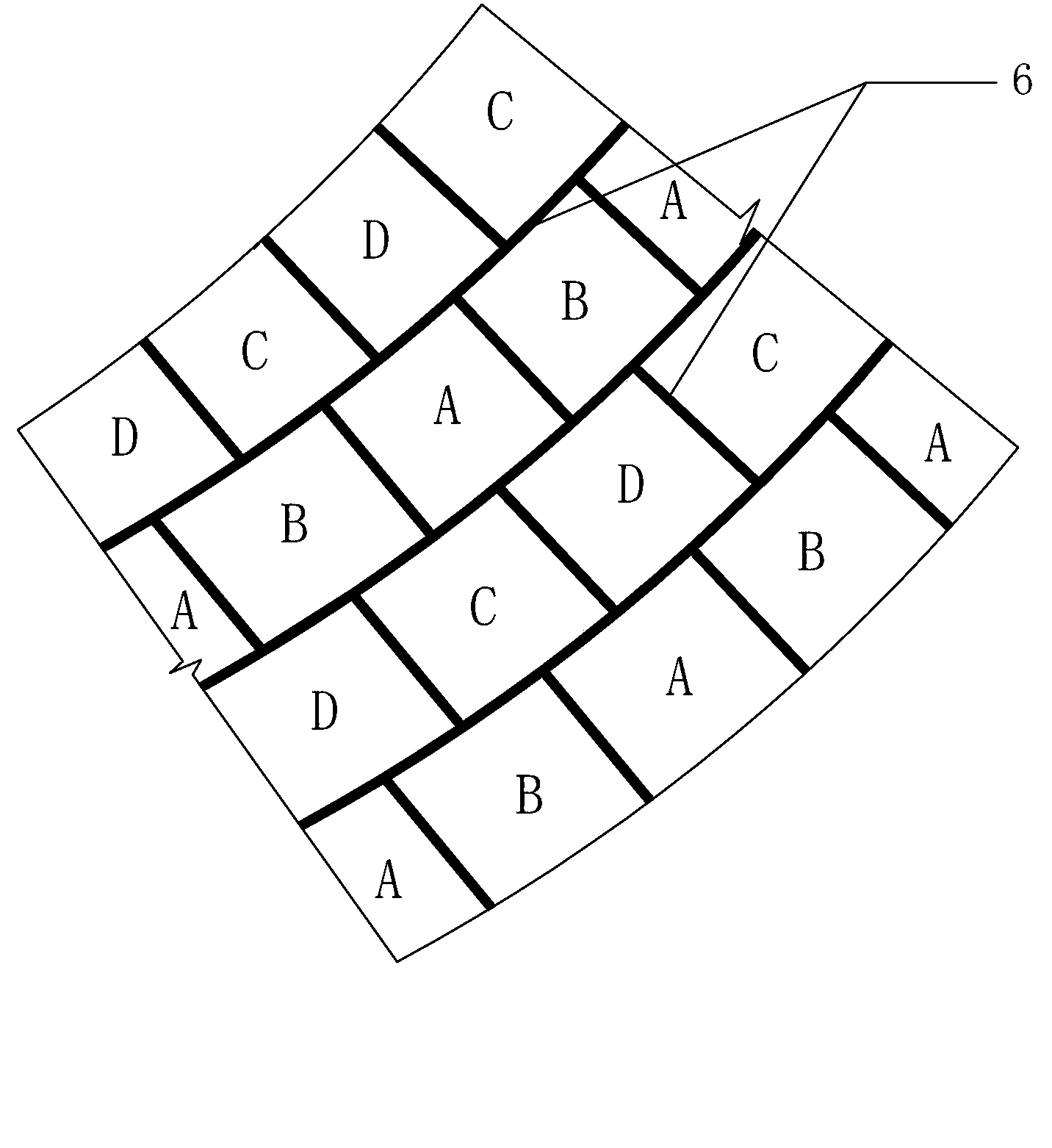

[0024] see now figure 2 , figure 2 It is a schematic diagram of the local arrangement and pouring sequence of the expansion joints of large-area refractory castables according to the embodiment of the present invention.

[0025] The large-area refractory castable construction expansion joint leaving method of the present invention is characterized in that comprising the following steps:

[0026] a. Describe the location and size of the refractory castable construction expansion joints in the working layer of the furnace according to the design drawings. The working ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com