Detector for detecting axial displacement degree of coupling

A technology of axial displacement and coupling, which is applied to instruments, measuring devices, mechanical measuring devices, etc., can solve problems such as difficulty in confirming the bearing and total shaft movement coefficient, heavy spare parts, and missed detection and misjudgment of equipment maintenance. , to achieve the effect of eliminating hidden dangers of equipment accidents, easy to carry and easy to carry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

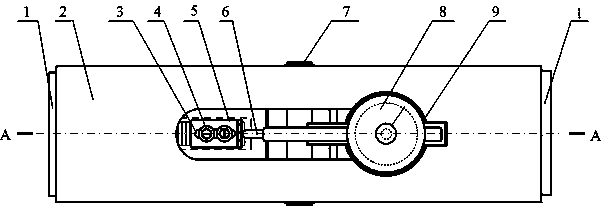

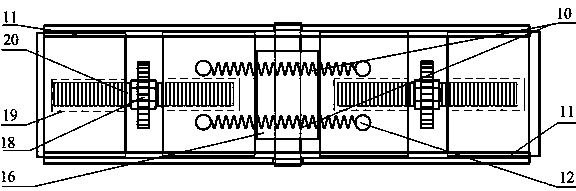

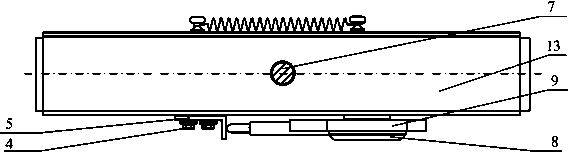

[0031] see Figure 1 to Figure 5 , a coupling axial displacement detector, comprising: a telescopic sliding top block assembly 1, a rotatable square shaft assembly 7, a tension spring 10, a housing, a dial indicator 8, a dial indicator insert 9, and a push rod Block 5;

[0032] A rotatable square shaft assembly 7 is housed between the two telescopic sliding top block assemblies 1, and two extension spring fixing columns 12 are installed on the top of the telescopic sliding top block assembly 1, and two extension springs 10 are mounted on four extension springs. Two telescopic sliding top block assemblies 1 are connected on the fixed column 12 .

[0033] Shell 2,13 is housed on telescopic sliding top block assembly 1 and rotatable square shaft assembly 7 bottom surfaces and both sides, and the middle part of bottom surface shell 2 has long ell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com