Low-frequency vibration-isolation combined sandwiched structure

A sandwich structure and vibration isolation technology, which is applied in the direction of layered products, rubber layered products, sound-generating devices, etc., can solve the problems of heavy structure, inability to effectively block low-frequency vibration, and difficulty in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

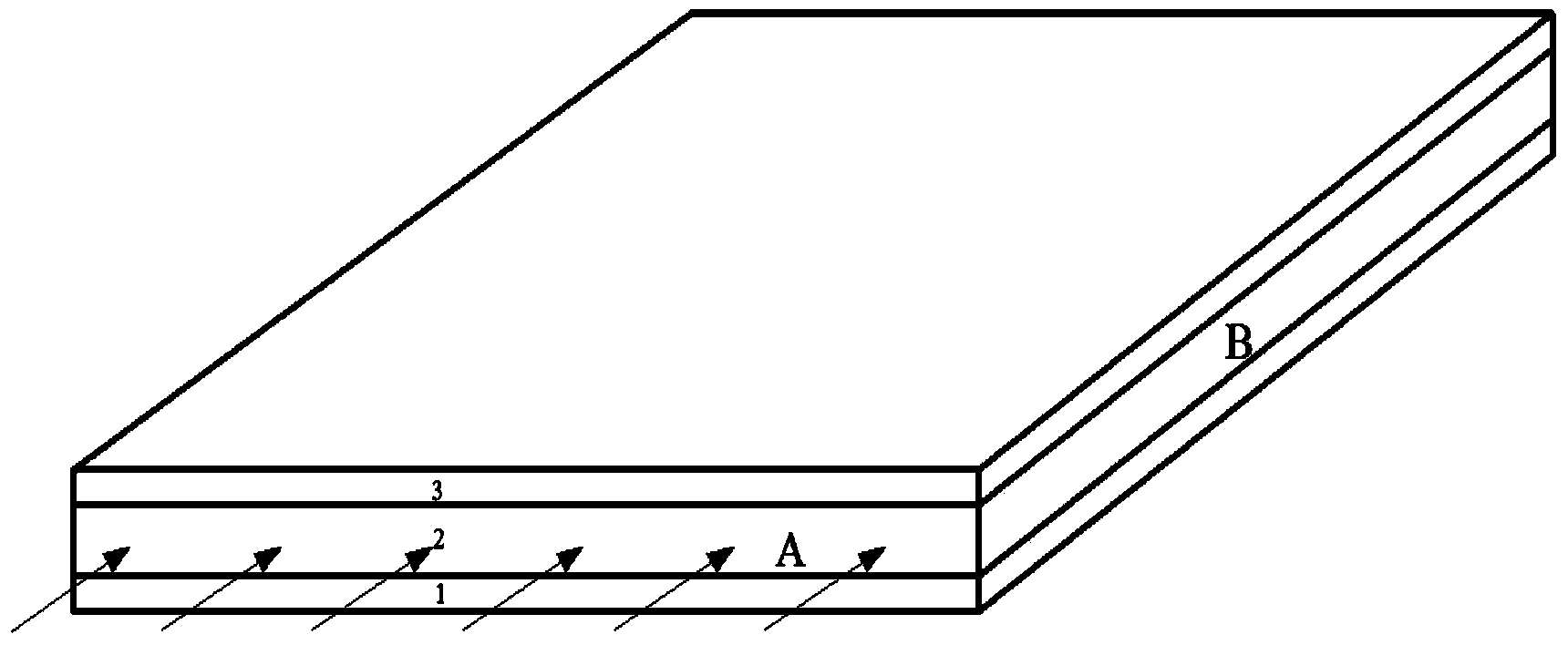

[0029] like figure 1 As shown, the present invention is divided into 3 layers, the lower uniform layer 1, the middle layer 2 and the upper uniform layer 3 arranged sequentially from bottom to top, the total thickness of the lower uniform layer 1, the middle layer 2 and the upper uniform layer 3 is 0.3cm -1.5cm. The area of the sandwich plate can be set according to the actual environment, but because a single plate is too large, it will affect the effect of fixed constraints on wave propagation in the structure. The cross-sections of the lower uniform layer 1, the middle layer 2 and the upper uniform layer 3 are A square with an area not exceeding 1m x 1m.

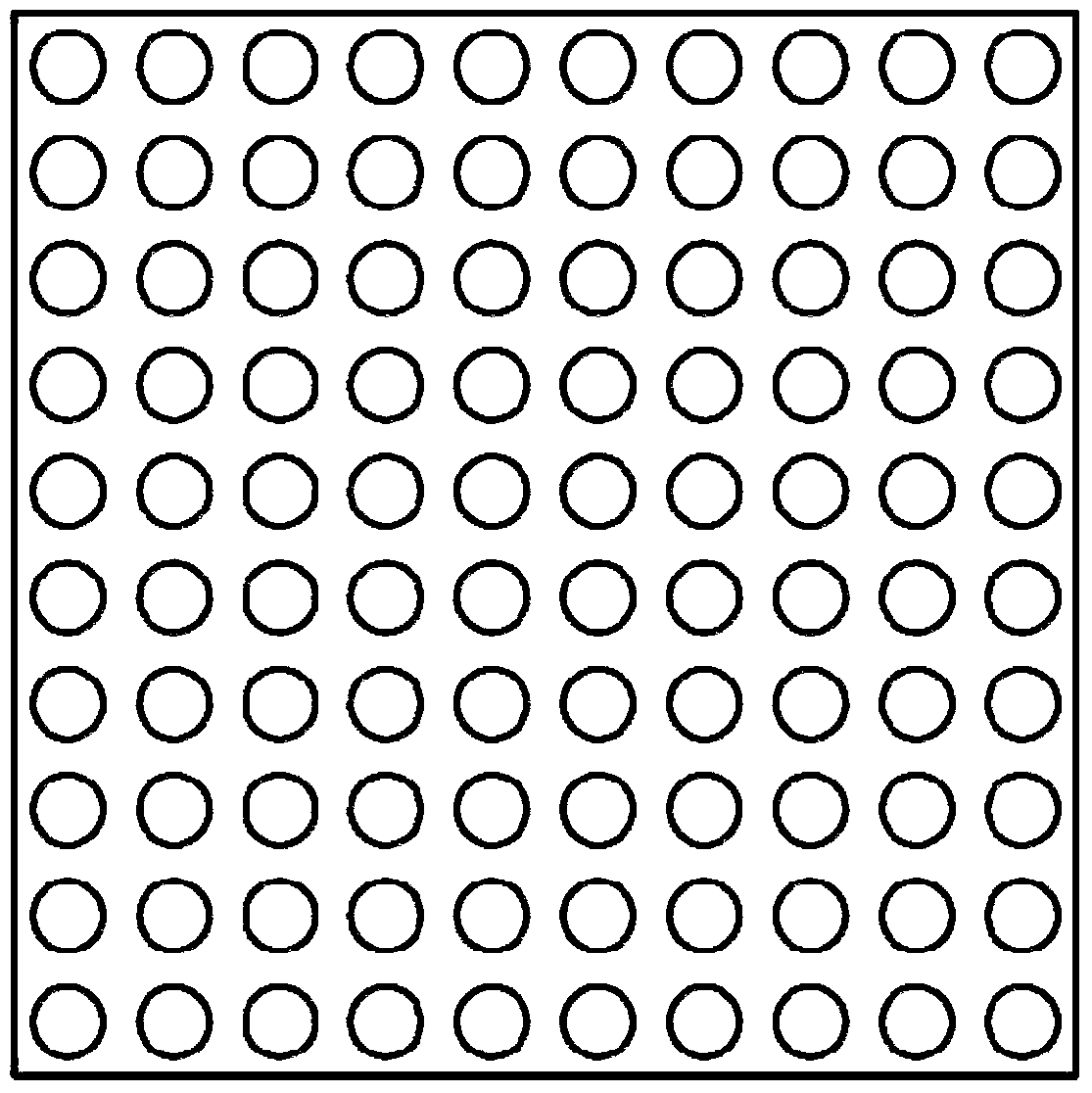

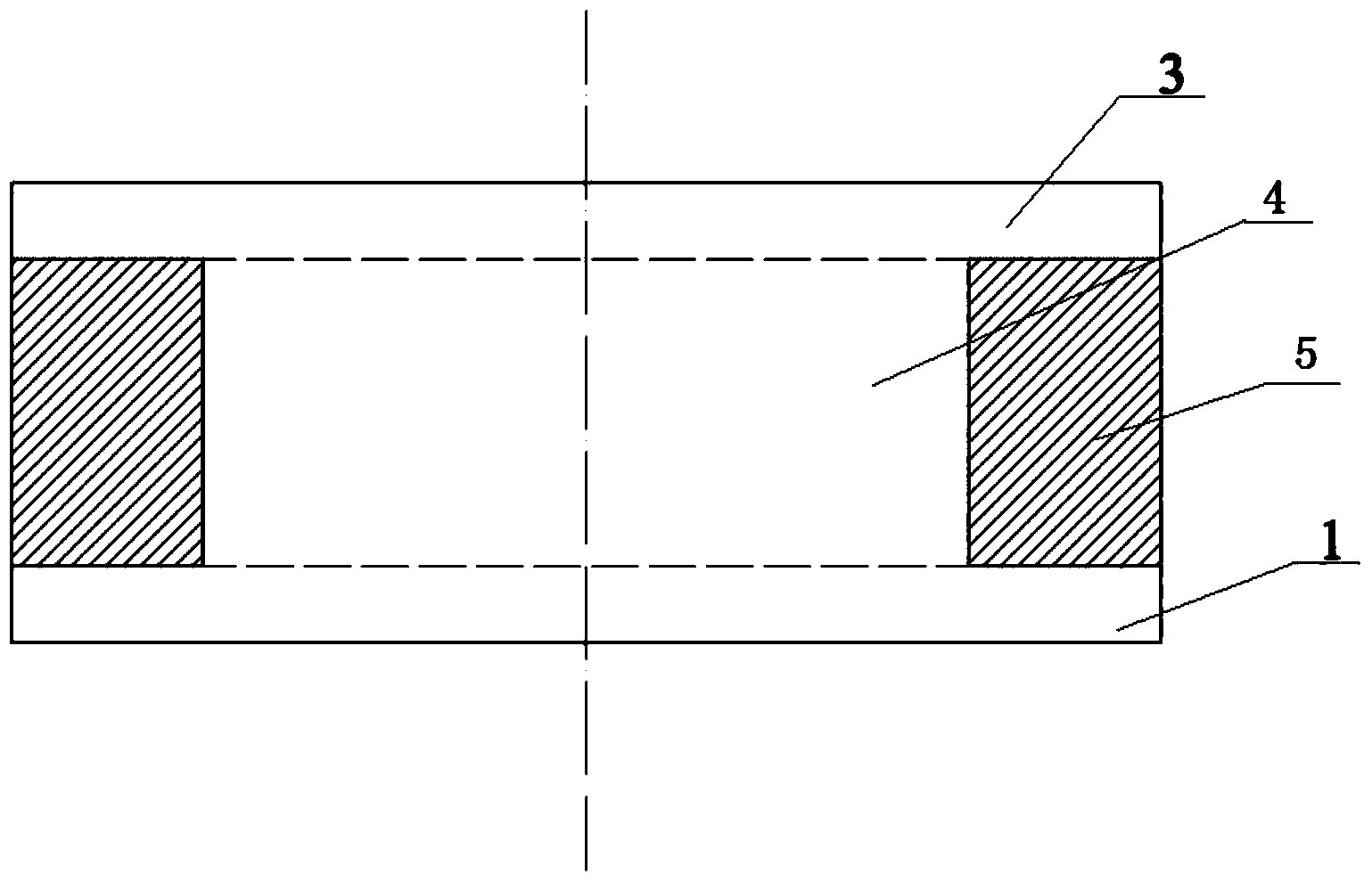

[0030] like Figure 2-3As shown, the middle layer 2 is a finite two-dimensional phononic crystal structure. The finite two-dim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com