Plant cutter

A cutting machine, plant technology, applied in the direction of cutters, harvesters, agricultural machinery and implements, etc., can solve the problems of high energy consumption and complicated assembly structure, and achieve the goal of reducing packaging and transportation costs and reducing the packaging size of the whole machine. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

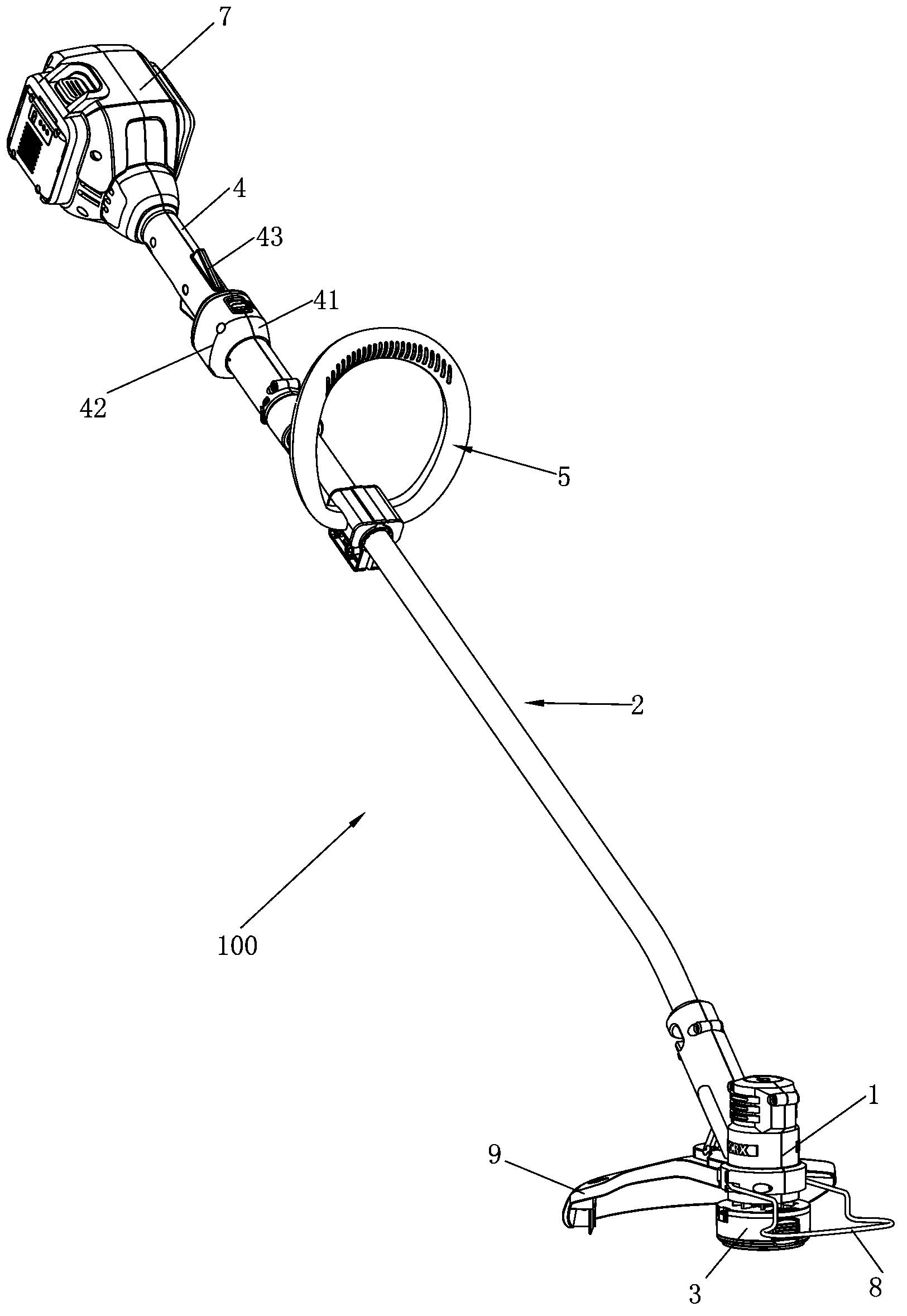

[0036] In this embodiment, the lawn trimmer is taken as an example to illustrate the plant cutting machine. Of course, the plant cutting machine in the present invention also includes brush cutters, edge trimmers and other garden machines with longitudinally extending joysticks.

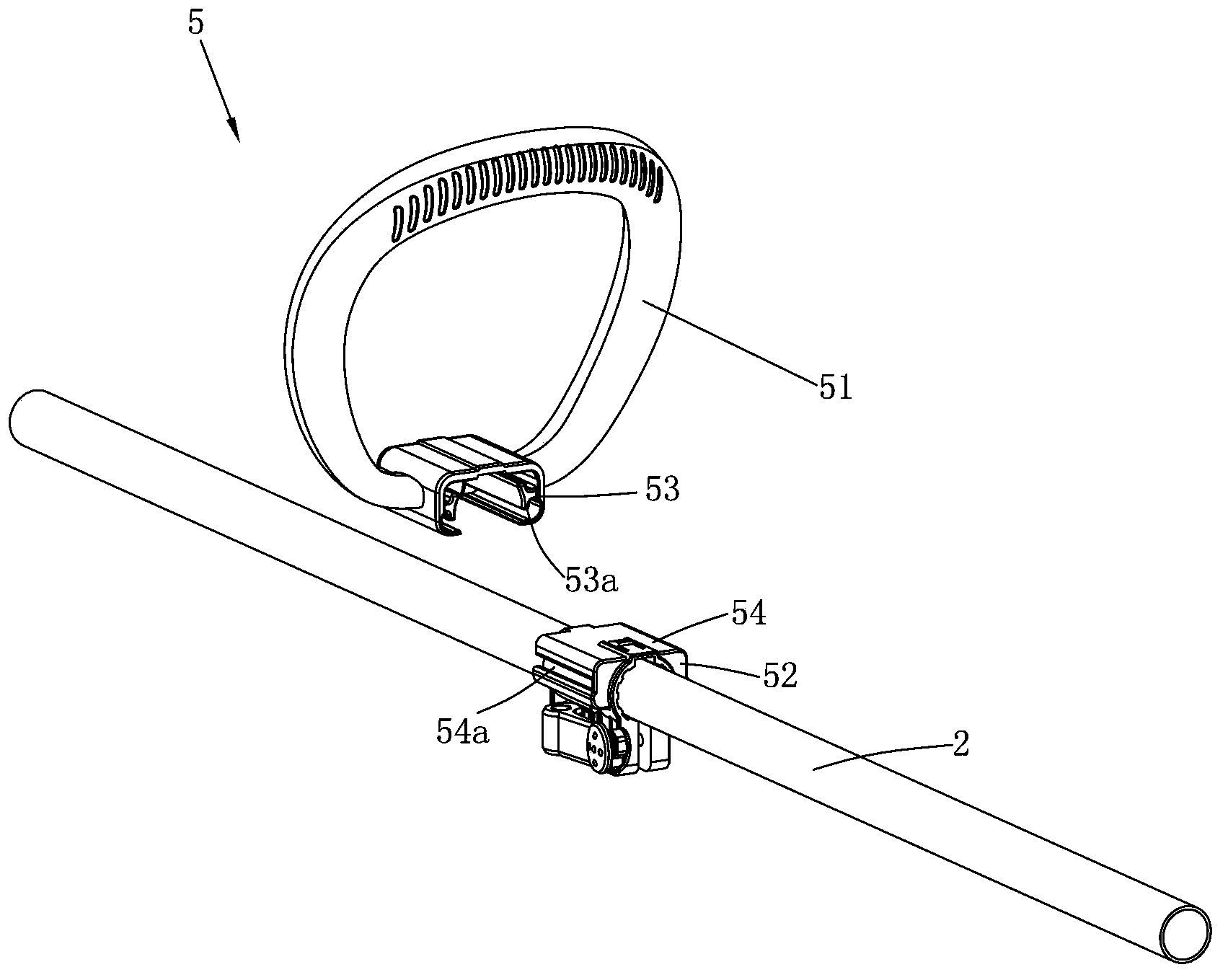

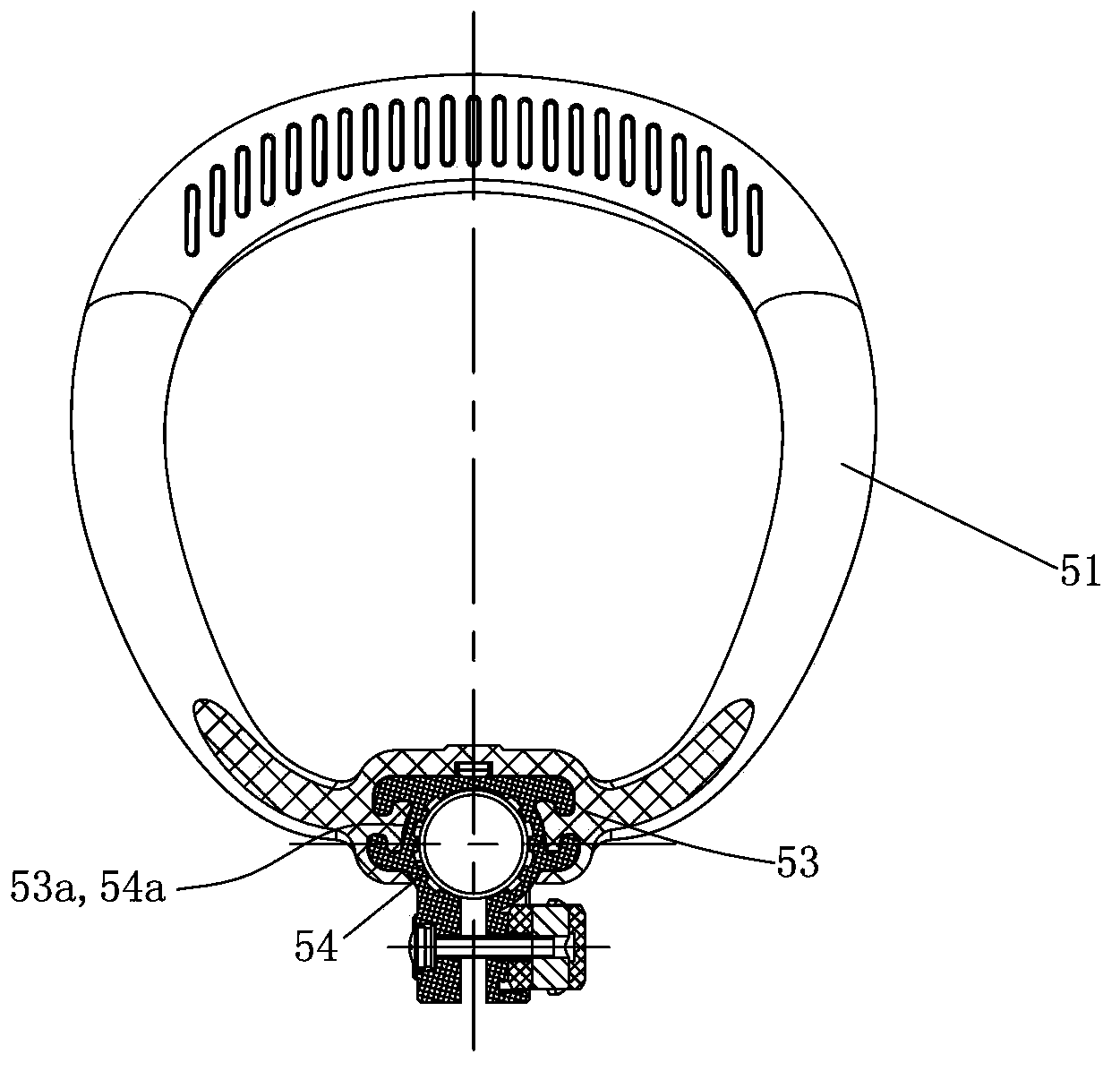

[0037] refer to figure 1 As shown, the mower 100 in this embodiment is a hand-held mower 100, including a joystick 2 extending longitudinally. Preferably, the joystick 2 is made of metal material aluminum, which is light in weight and not easily damaged. Of course, The material of the joystick 2 can also be resin or other lightweight materials. One end of the joystick 2 is connected with a power source receiving device for receiving the power source. The mower 100 in this embodiment is a DC electric mower 100, and the power source receiving device is a battery pack connecting device 7, which can A battery pack is connected to provide power for the lawn trimmer 100 . Of course, the lawn trimmer 100 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com