A bearing integrated maintenance device and method

A technology for maintenance and bearings, applied in chemical instruments and methods, cleaning methods using liquids, dry gas arrangement, etc., to achieve the effects of convenient operation, uniform and full oiling, and fast cleaning and oiling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In the front-line or field environment maintenance of the aircraft, it is required to clean and check the wheel bearings and refill the grease every 20 to 30 landings or when the bearings are suspected of being poorly lubricated. This work has been done by hand with a brush dipped in kerosene (or gasoline) to clean the bearings and press grease with hands. The disassembled bearings need to be efficiently cleaned, inspected and re-lubricated under the first-line environmental conditions of the airport (outfield) to ensure the smooth completion of accompanying tasks, reduce ground maintenance support time, improve front-line maintenance working conditions, and improve the integrity of the aircraft rate and re-dispatching rate are significant. Therefore, the present invention provides an integrated bearing maintenance device and method.

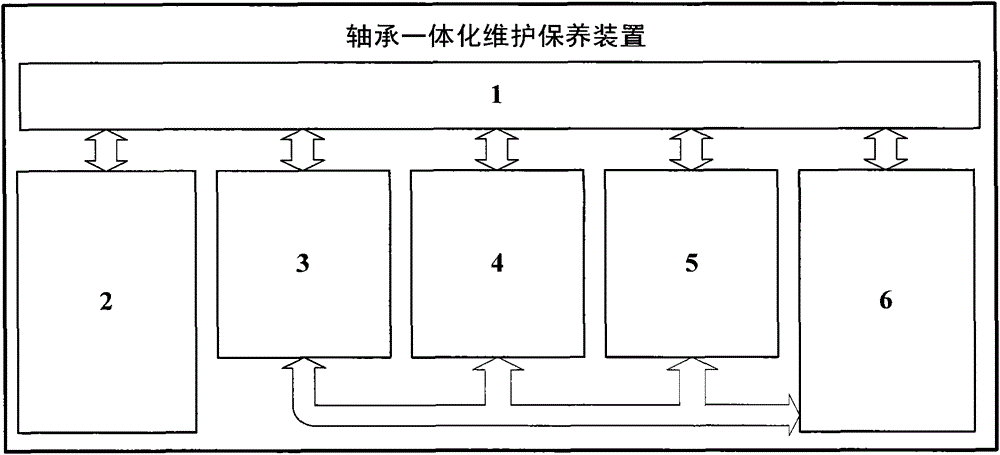

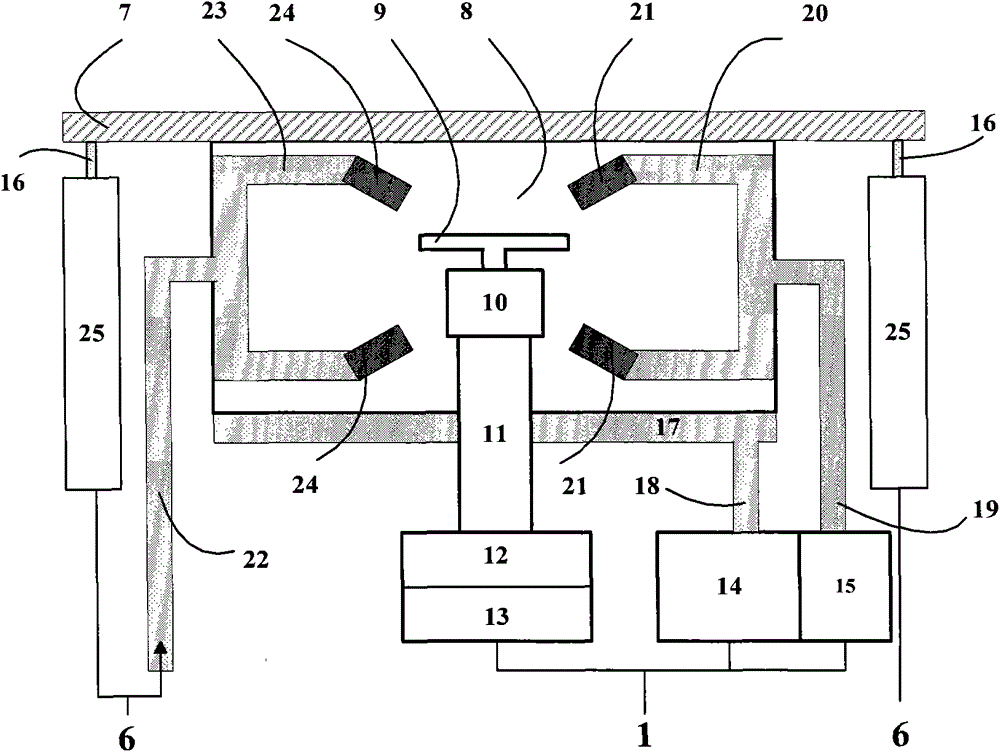

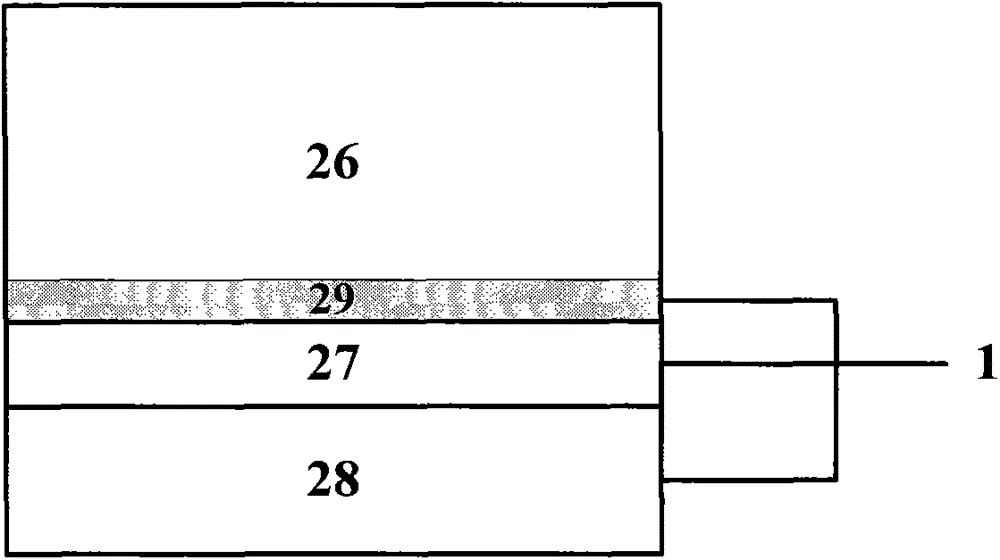

[0062] 1. Bearing integrated maintenance device

[0063] The bearing integrated maintenance device of the present invention includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com