Circular saw web cutting machine

A technology for cutting machines and circular saw blades, which is applied in the direction of metal sawing equipment, sawing machine devices, sawing machine accessories, etc., and can solve problems such as low precision, incomplete functions, and limited cutting height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

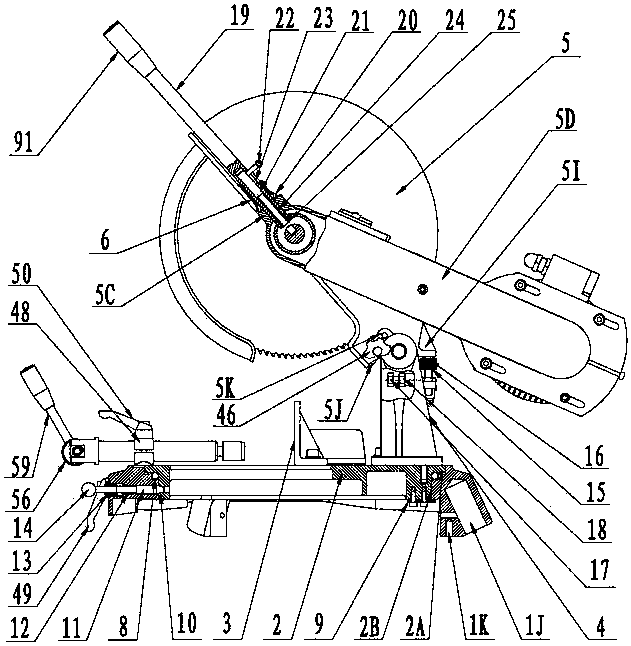

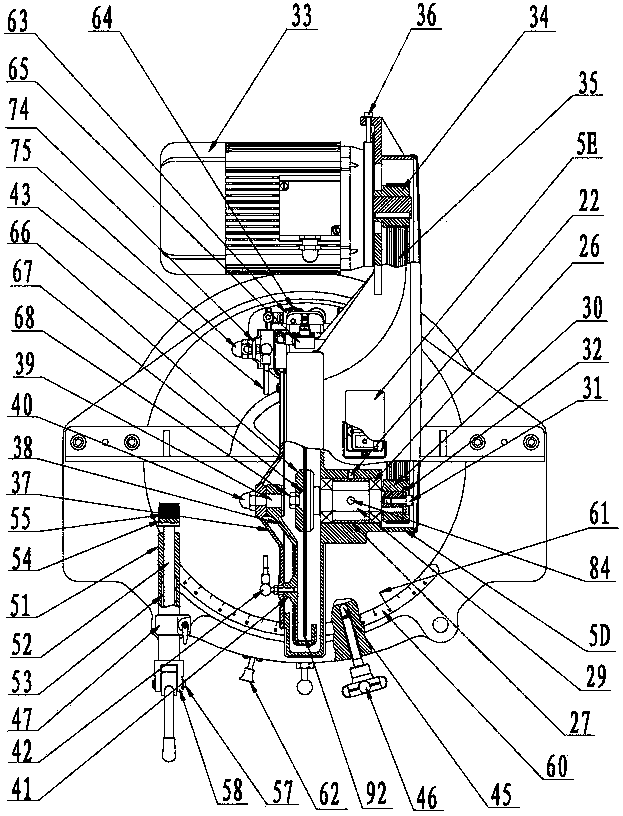

[0050] Such as figure 1 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 and Figure 16 As shown, the rotating workbench 2 of the present invention is horizontally placed in the central hole of the fixed workbench 1, the positioning surface of the positioning backing plate 3 is placed on the table top of the fixed workbench 1 transversely towards the front, and the swing support 4 is arranged on On the rotating worktable 2 behind the positioning leaning plate 3, the power assembly AA is placed on the swing support 4.

[0051] Such as figure 2 , Figure 6 As shown, the fixed workbench 1 includes a central central hole 1A, two-stage concave circular platforms 1B, 1C, a small fan-shaped step 1D, a longitudinal hole 1H, an internal thread 1I horizontally facing the center of the central hole, a vertical circular hole 1E, and a horizontal horizontal circular hole 1F , Foot 1G, foot hole 1J, foot internal thread 1K.

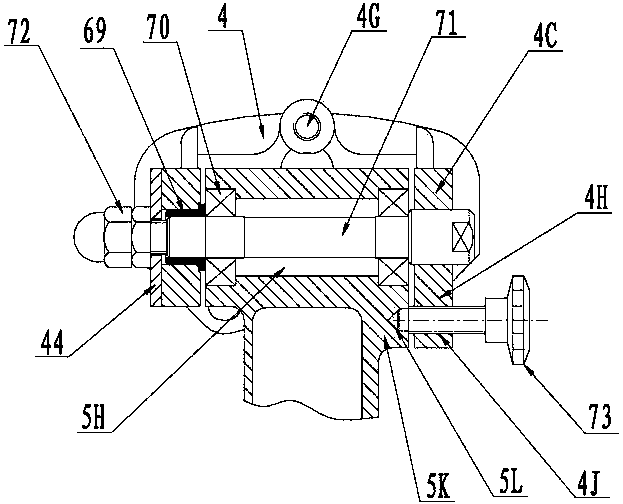

[0052] Such as image 3 As shown, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com