A kind of polymer powder slush molding test method and device

A slush molding and testing device technology, applied in coating and other directions, can solve problems such as affecting the production progress and economic benefits of enterprises, consuming a lot of resources, etc., and achieve the effects of short test period, less materials, and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

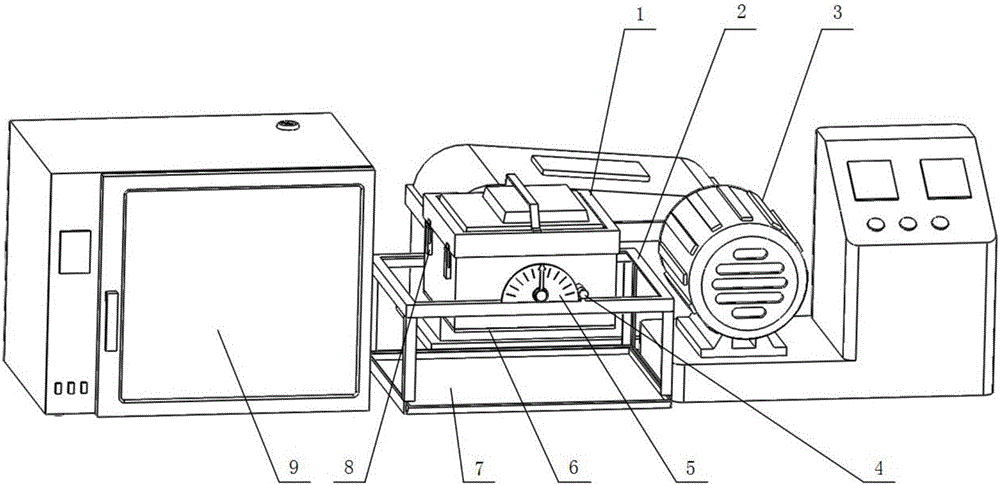

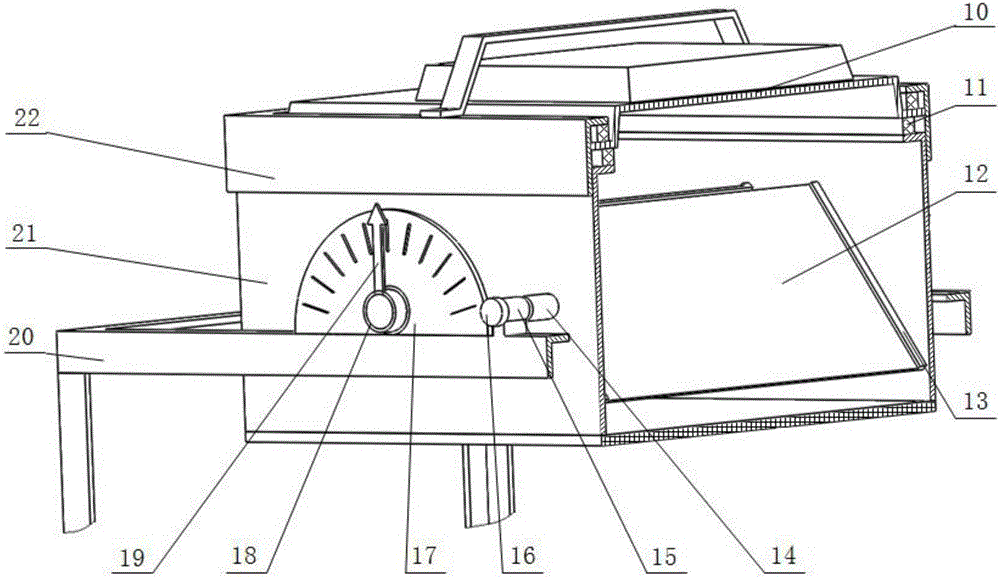

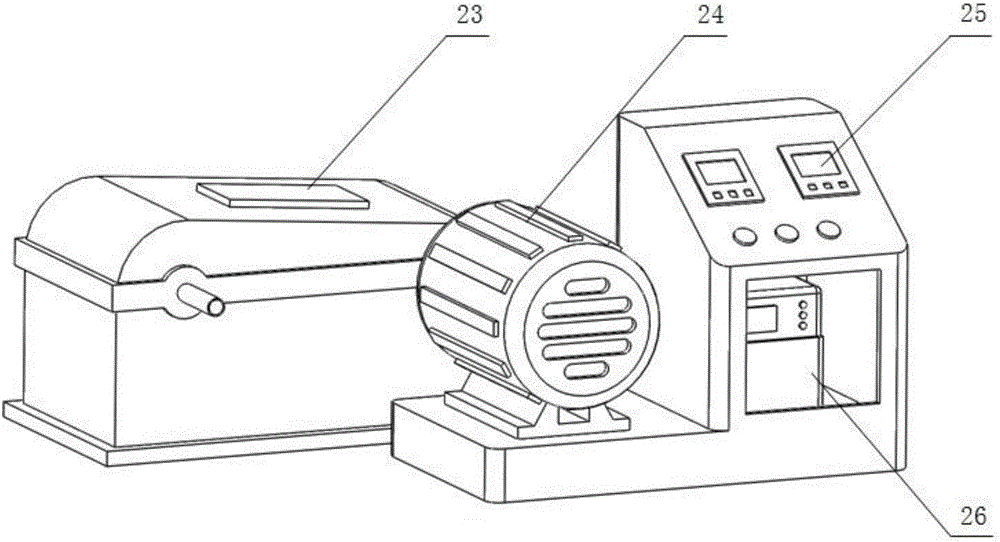

[0040] like Figure 1-4 As shown, a polymer powder slush molding test device consists of a powder box mechanism 1, a slush molding frame 2, a driving mechanism 3, a sealing mechanism 11, a locking mechanism 8, a stop mechanism 4, a visible window 6, It is composed of angle scale 5, movable guide plate 12, mold 10, oven 9 and other parts. The above-mentioned powder box mechanism 1 can rotate around a horizontal rotating shaft 18 installed on the slush molding machine frame 2 . The locking mechanism 8 is located on the left and right sides of the powder box mechanism 1, and the visible window 6 is located at the bottom of the powder box mechanism 1. When the powder box mechanism 1 is rotated to a proper position, the inside of the powder box mechanism 1 can be observed through the visible window 6 The powder and mold 10 situation. The stop mechanism 4 is located on the powder box mechanism 1 and the slush molding frame 2; the dial 17 is fixedly connected with the slush molding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com