Installation structure of a hydraulic interconnection suspension system

A technology of hydraulic interconnection suspension and installation structure, applied in interconnection system, suspension, transportation and packaging, etc., can solve the problems of frame collision, damage, vibration and noise, so as to make up for manufacturing errors and ensure normal work. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

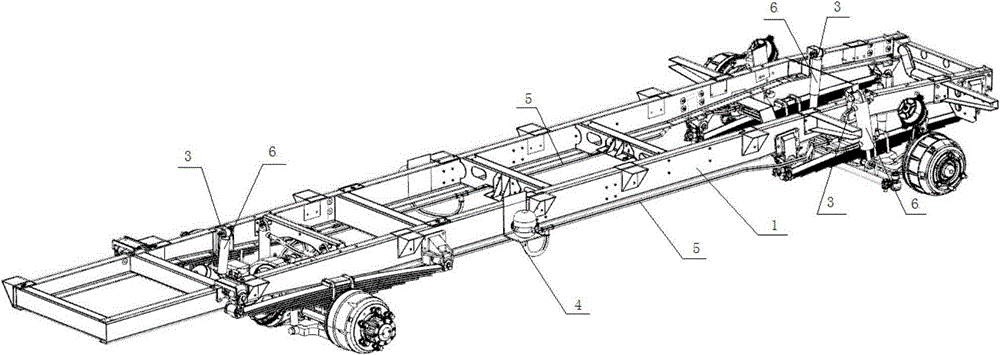

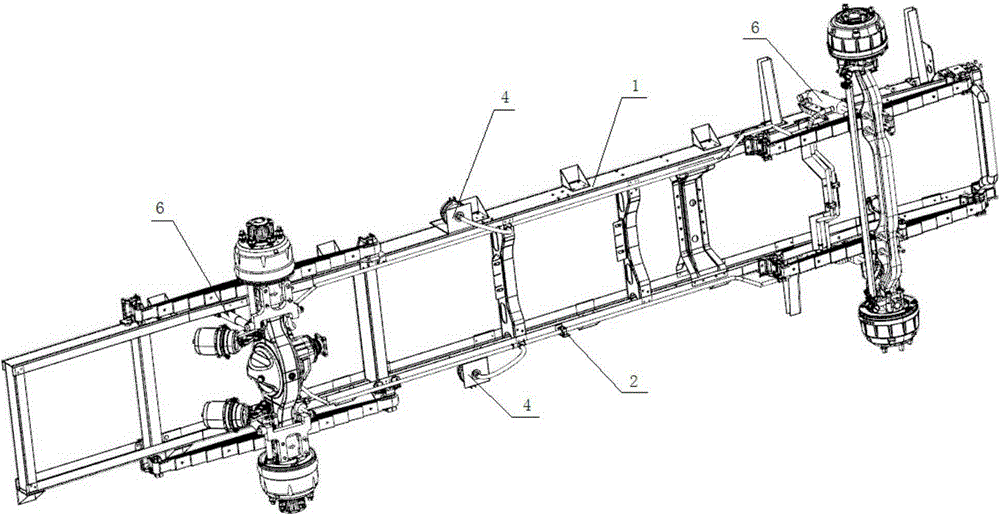

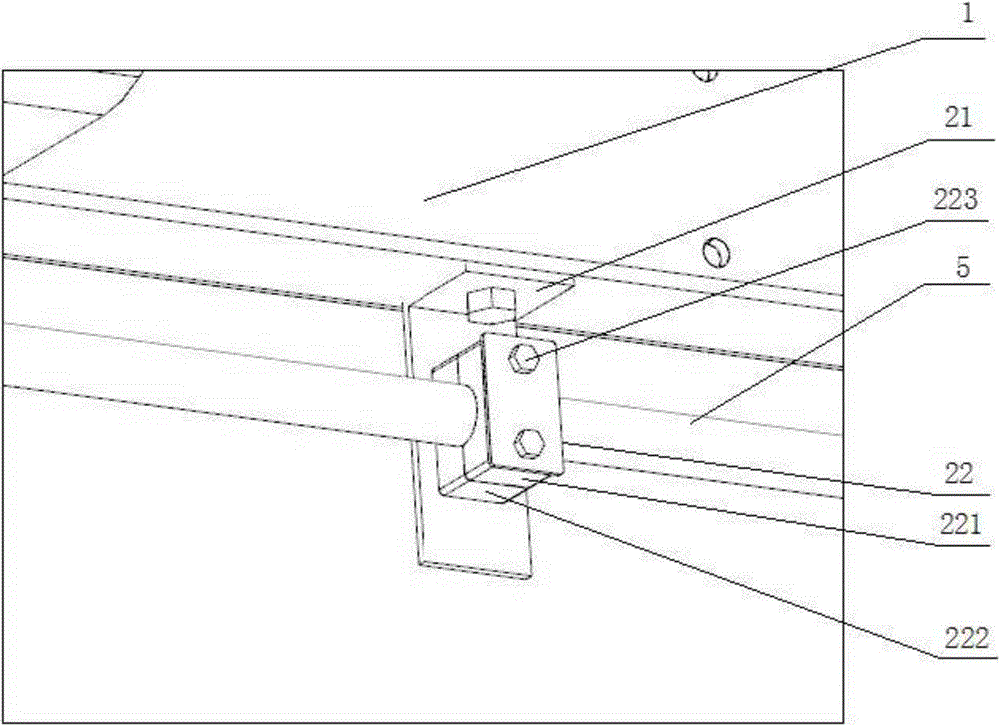

[0019] Such as Figure 1-5 As shown, an installation structure of a hydraulically interconnected suspension system includes several hard pipe fixing devices 2, hydraulic cylinder fixing devices 3 and accumulator fixing devices 4 arranged on the vehicle frame 1, and the hard pipe fixing device 2 includes The mounting seat 21 arranged on the vehicle frame 1 is provided with a waist-shaped hole, and the mounting seat 21 is provided with a hard pipe clip 22 . The hard pipe clamp 22 includes an upper clamping block 221 and a lower clamping block 222, and semicircular grooves are respectively arranged in the upper clamping block 221 and the lower clamping block 222, and elastic pads (not shown in the figure) are arranged in the grooves. The two sides of the upper clamping block 221 are respectively provided with upper mounting holes, and the corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com