H-shaped drag reduction ship and working principle

A ship bottom and hull technology, applied in the direction of hull, ship construction, hull parts, etc., can solve the problems of unfavorable mass production and use of ships, complex hull structure, unfavorable use of ships, etc., and achieve low resistance, simple hull manufacturing, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

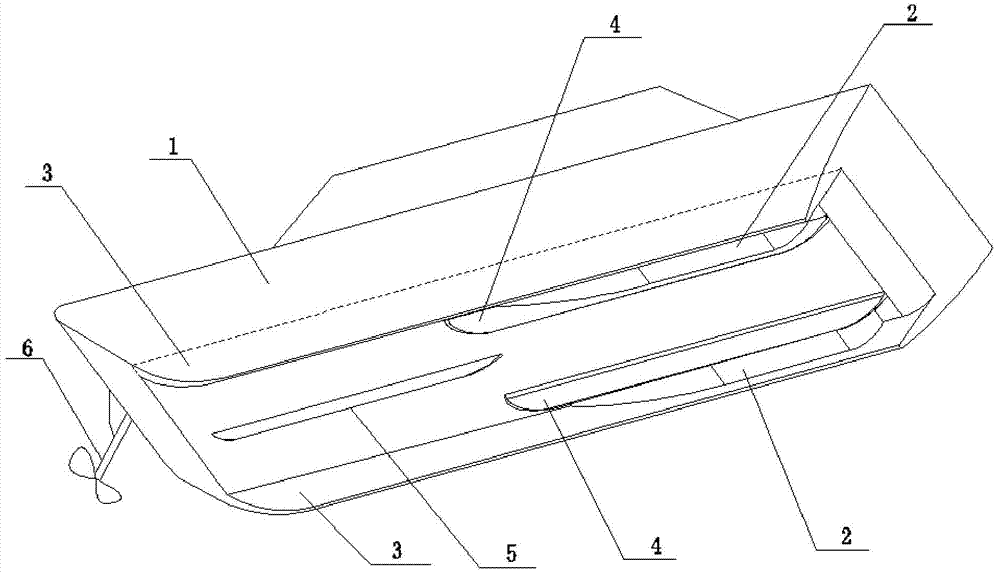

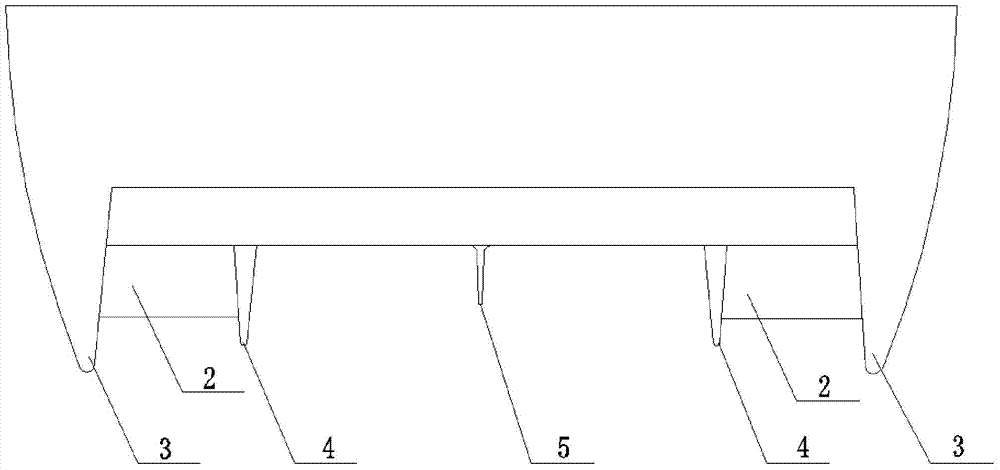

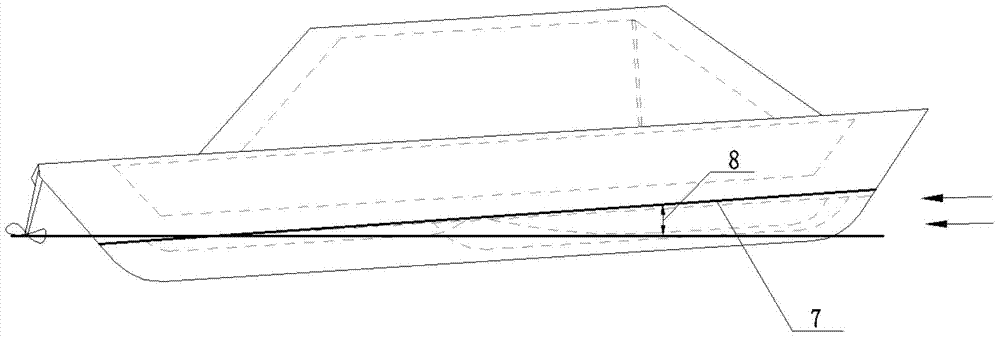

[0018] Such as figure 1 , figure 2 , image 3 As shown, an H-shaped boat used in inland rivers and lakes, including the main hull 1 and auxiliary hulls 2 on both sides; The bottom surface of the ship gives the ship a thrust; when the surface paddle 6 pushes the ship, a large amount of air enters the bottom of the ship, and the horizontal plane forms an elevation angle 8 with the hull waterline 7, and as the air continues to enter, the elevation angle continues to increase. The H-shaped wings 3 on both sides of the main hull surround the air at the bottom of the ship to prevent side leakage of air; the wings 4 on the inside of the auxiliary hull and the wings 3 of the main hull divide the space surrounded by the wings 3 of the main hull into three closed spaces open forward. Space; under the action of air lift, three high-pressure air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com