Micro-surfacing mixture mineral aggregate grading optimization design method

A micro-surfacing mixture and optimized design technology, which is applied in the field of highway asphalt pavement maintenance engineering, can solve the problems of poor crack resistance, insufficient anti-loosening performance, neglect of micro-surfacing mixture, etc., and achieve good high temperature stability and resistance Sliding performance, accurate and reliable test data, and good promotional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

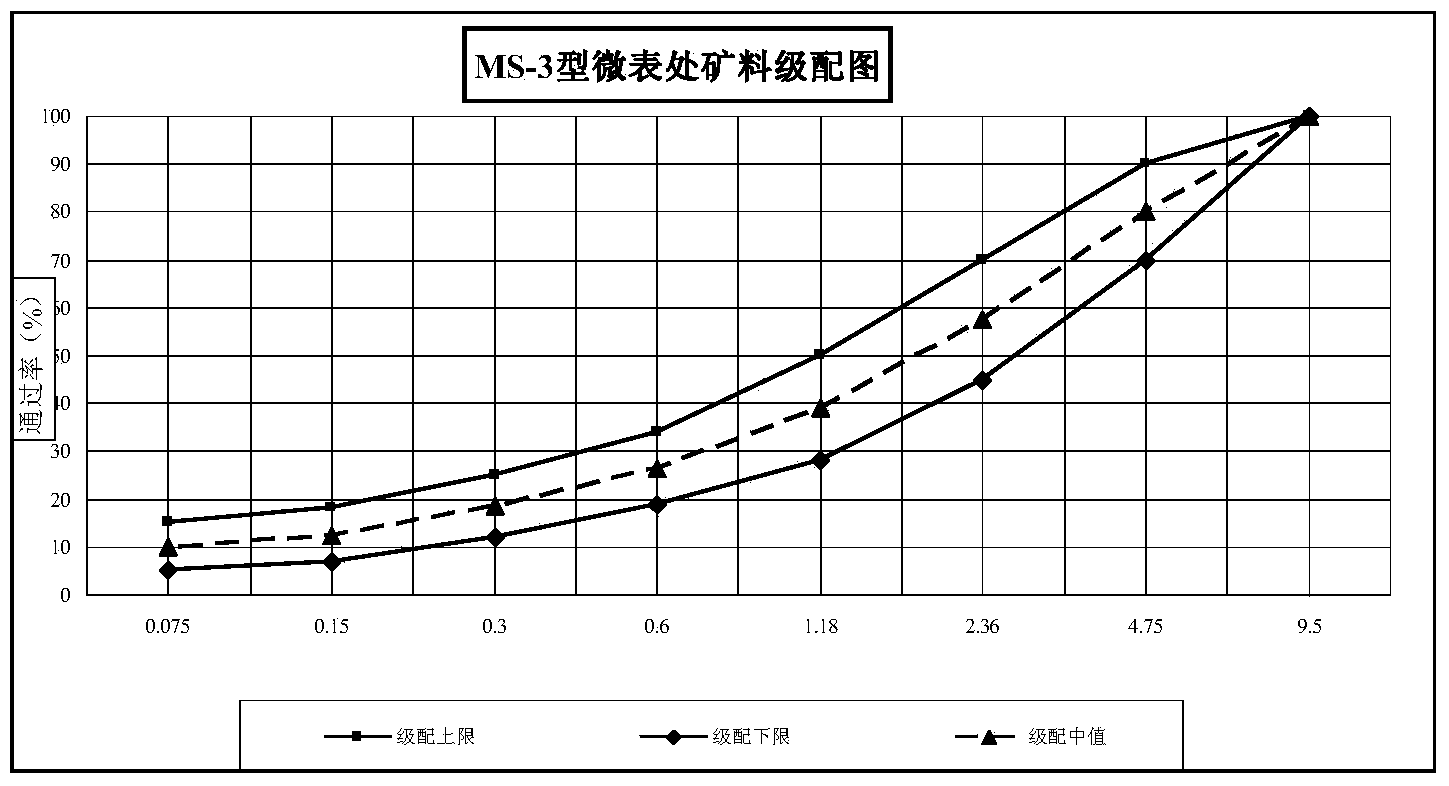

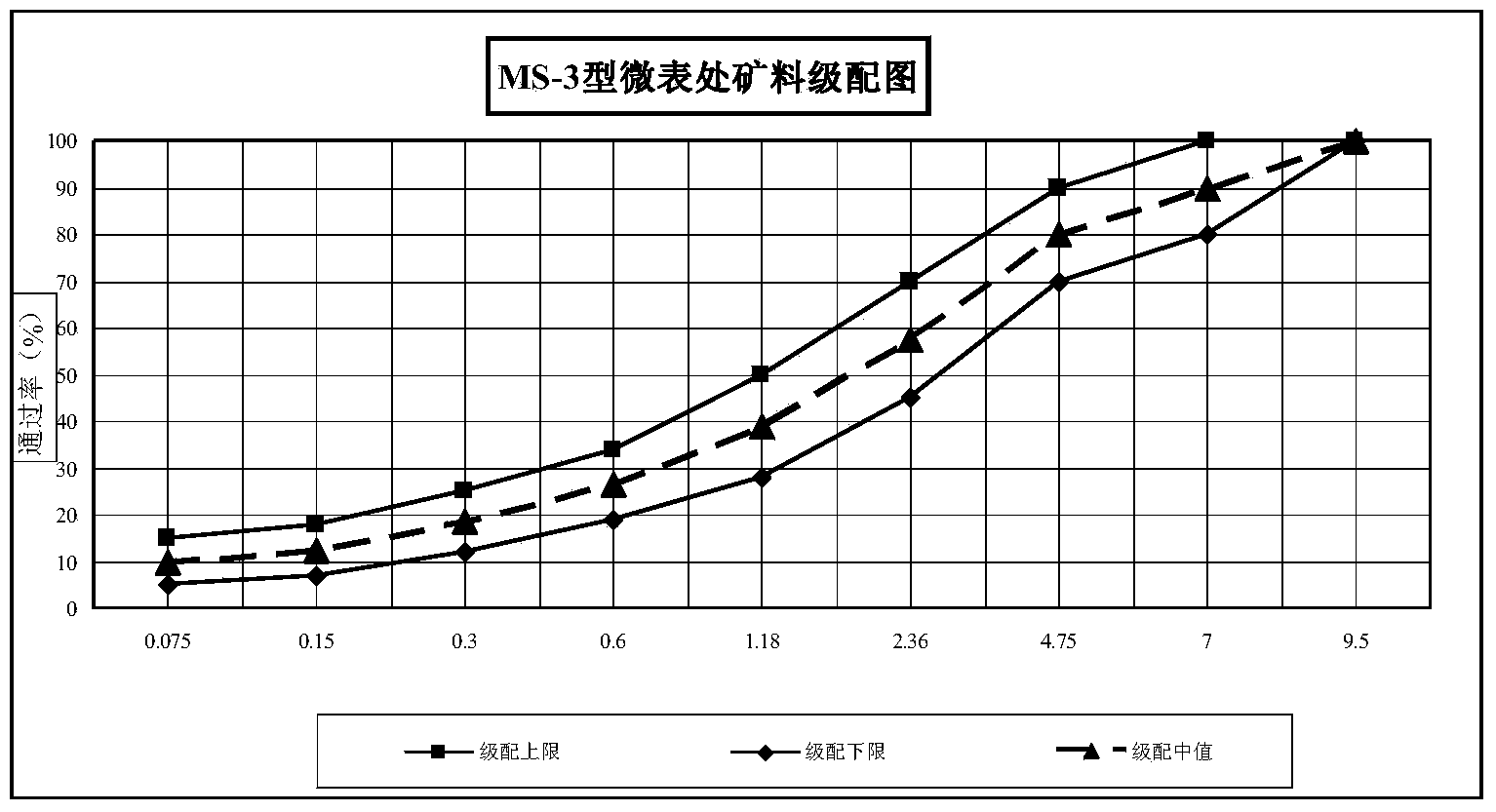

[0039] In the following, in conjunction with the embodiments and the drawings, the process of the optimization design method of the mixture mineral gradation at the micrometer of the present invention will be specifically described by taking the MS-3 type micrometer as an example.

[0040] The base asphalt used in this example is Panjin Grade A No. 90 asphalt, the emulsifier is the CMK-20 slow-cracking fast-setting cationic emulsifier produced by Henan Luohe Tianlong Chemical Co., Ltd., and the modifier is produced by Henan Luohe Tianlong Chemical Co., Ltd. SBR latex, the PH regulator is hydrochloric acid, the coarse and fine aggregates are limestone from the local Taomengou gravel quarry in Yinchuan, Ningxia, the filler is a small amount of P.O42.5 cement, and the formulation of the micro-surface mixture is aggregate: cement :Water=100:1:7, the ratio of oil to stone is 6.3%

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com