A kind of sila dehydro herbal ketone and preparation method thereof

A technology of dehydroherbone and sila, which is applied in the compound field of sila dehydroherbone, and achieves the effects of high separation yield, easy availability of raw materials, simple experimental equipment and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

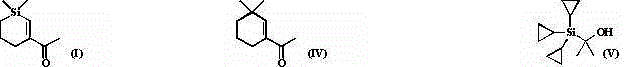

Embodiment 1

[0026] Add 1 mol of 1,1-dimethylsilacyclobutane II, 1 mol of 3-butyn-2-one III, 1% equivalent of Pd(PPh 3 ) 4 and 5L of benzene solvent, heated to 80°C, and reacted with magnetic stirring for 4 hours. Concentrate after the reaction, decolorize and separate on a silica gel column, and use a mixed solvent of petroleum ether: ether = 10:1 as the eluent to obtain the pure product sila dehydroherbalone I (purity>98%, colorless liquid), and the isolated yield is 50%. The NMR and high resolution mass spectrometry data of this compound are as follows: 1 HNMR (CDCl 3 )δ=6.80(s,1H),2.34-2.31(m,5H),1.81-1.76(m,2H),0.69-0.66(m,2H),0.13(s,6H); 13 CNMR (CDCl 3 )δ=200.35,156.47,138.19,27.75,25.32,20.95,11.14,-2.30.HRMS: m / z :calcdforC 9 h 16 OSi[M+H] + :169.1443, found 169.1449.

Embodiment 2

[0028] Add 2mol of 1,1-dimethylsilacyclobutane II, 1mol of 3-butyn-2-one III, 5% equivalent of (PPh 3 ) 2 PdCl 2 and 2L of benzene solvent, heated to boiling, and reacted with magnetic stirring for 2 hours. After the reaction, it was concentrated, decolorized and separated on a silica gel column, and a mixed solvent of petroleum ether: ether = 10:1 was used as the eluent to obtain the pure product sila dehydroherbone I with an isolated yield of 65%. See Example 1 for NMR and high-resolution mass spectrometry data.

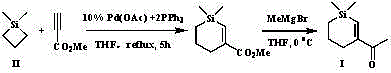

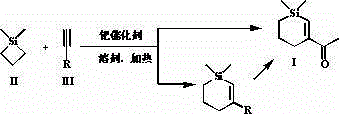

[0029] The reaction formula of embodiment 1 and embodiment 2 is as follows:

[0030]

[0031] Synthesis of siladehydroherbone I by two-step reaction

Embodiment 3

[0033] Into a 10 L round bottom flask, add 1 mol of 1,1-dimethylsilacyclobutane II, 1 mol of methyl propiolate, 10% equivalent of Pd(OAc) 2 +2PPh 3 and 5L tetrahydrofuran solvent, heated to boiling, and reacted with magnetic stirring for 5 hours. Concentrate after the reaction, decolorize and separate on a silica gel column, use a mixed solvent of petroleum ether: ether = 5:1 as an eluent to obtain the pure product 1,1-dimethyl-3-methoxycarbonyl-silacyclohexene, and analyze The data can be found in the literature ( Bull.Chem.Soc.Jpn. , 1991, 64, 1461).

[0034] Add 10mmol of 1,1-dimethyl-3-methoxycarbonyl-silacyclohexene and 150mL of THF to a 250mL round bottom flask, then cool to 0°C with an ice bath, and slowly drop Add 10 mmol of MeMgBr, dropwise for 1 hour. The reaction was quenched with 1M dilute hydrochloric acid solution, the resulting solution was extracted three times with ether, the solvent was removed by rotary evaporation, decolorized and separated on a silica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com