Flood discharge and power generation energy dissipation hydropower station

A hydropower station and flood discharge technology, which is applied in the field of hydropower stations, can solve the problems of unusable flood discharge, large flood discharge flow, and large atomization, so as to avoid the problem of flood discharge atomization, broad development prospects, and the effect of energy dissipation and flood discharge atomization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

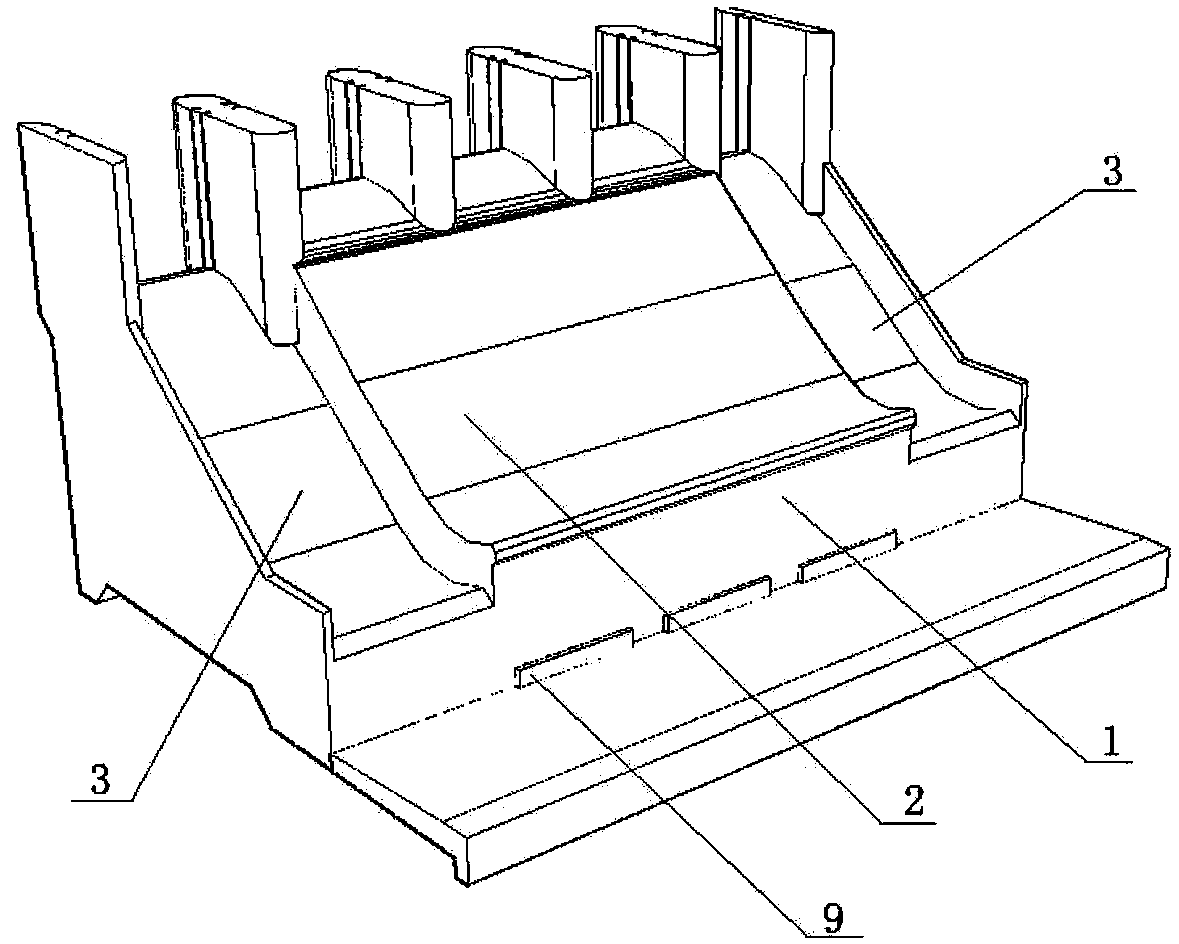

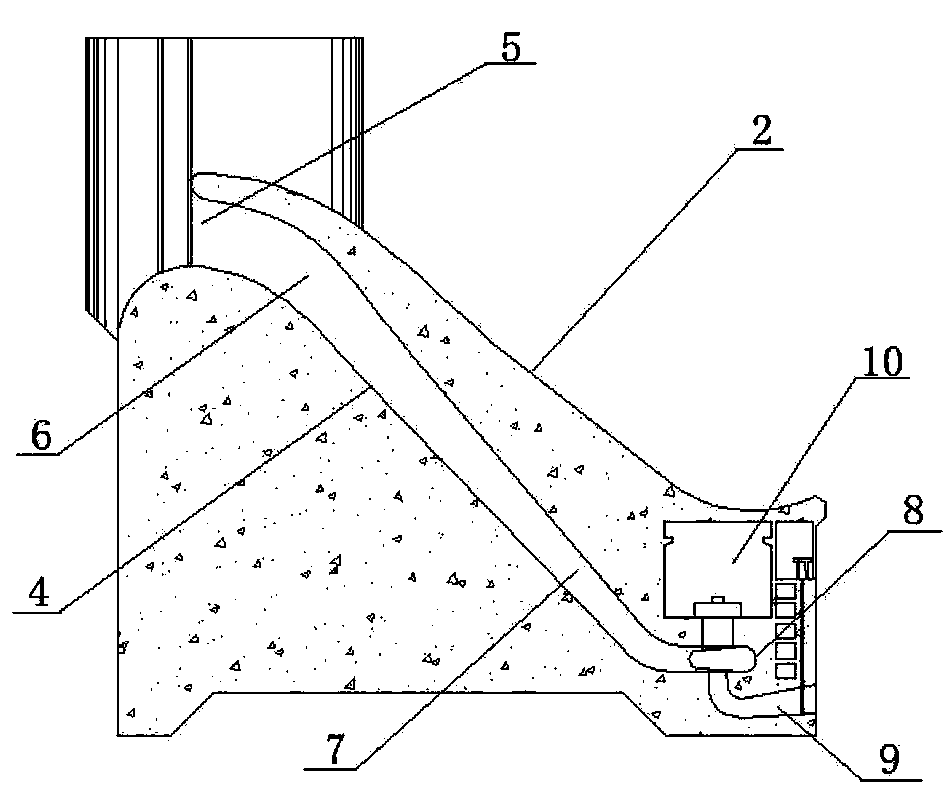

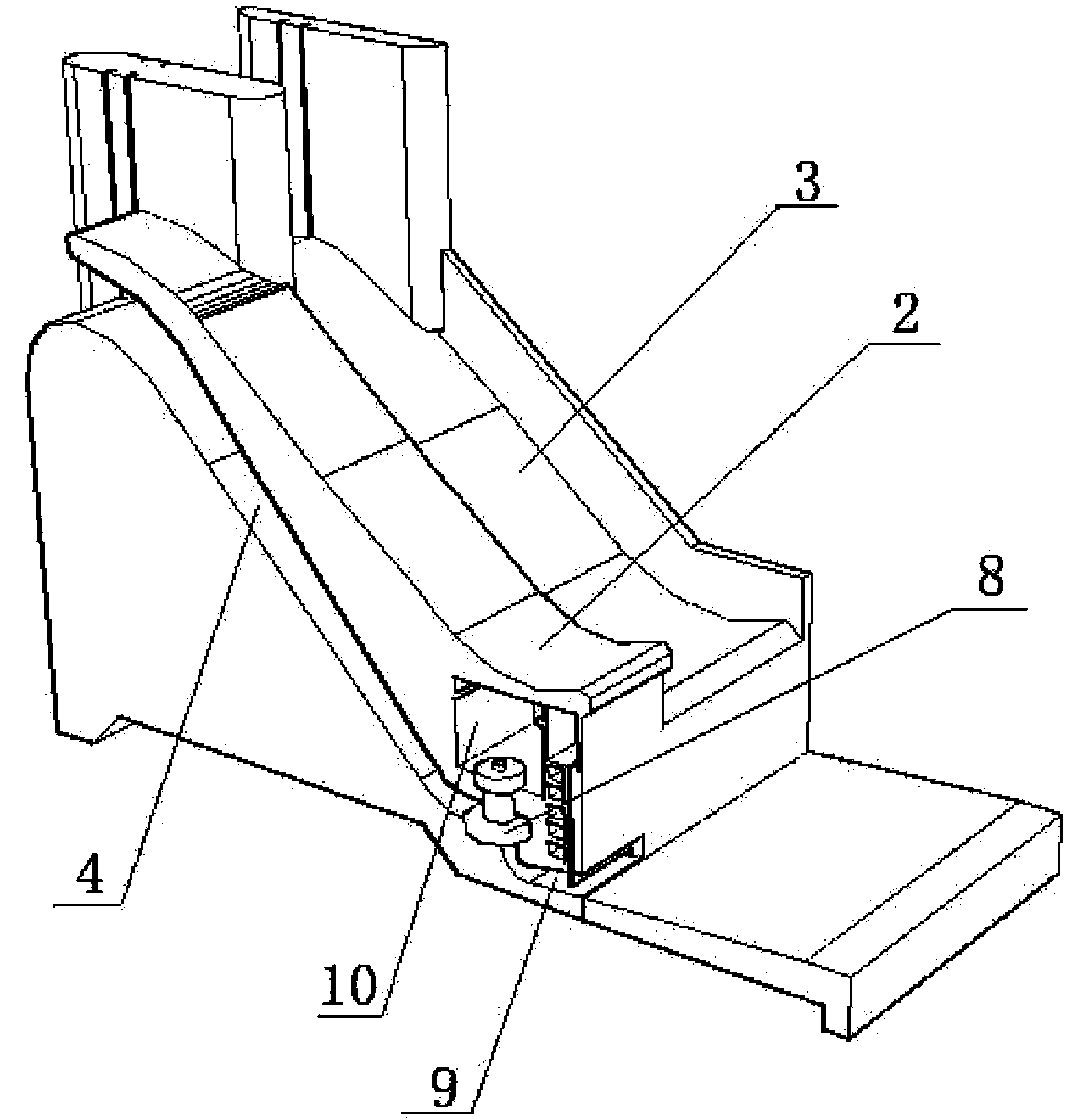

[0015] See attached Figure 1-3 As shown, a flood discharge power generation energy dissipation hydropower station, it includes flood discharge power generation energy dissipation system 1, diversion type conventional power generation system, conventional spillway 2 and extraordinary spillway 3, the flood discharge power generation energy dissipation system is set inside the overflow conventional spillway, the conventional flow dam section The middle part is the diversion channel 4 of the flood discharge power generation and energy dissipation system. The flood discharge power generation and energy dissipation system 1 is composed of water inlet 5, diversion channel 6, pressure pipe 7, water turbine 8 and draft pipe 9 from top to bottom. There is a factory building 10 outside the water turbine. , the regular spillway is set at the top of the diversion channel, the extraordinary spillway is set at both ends of the regular spillway 2, and the extraordinary spillway is lower than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com