Concrete pumping device and pumping oil cylinder

A technology for concrete pumps and oil cylinders, which is used in mechanical equipment, fluid pressure actuation devices, fluid pressure actuation system components, etc. The movement cannot be carried out alone, so as to avoid additional wear, improve the lubrication effect, and prevent eccentric wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

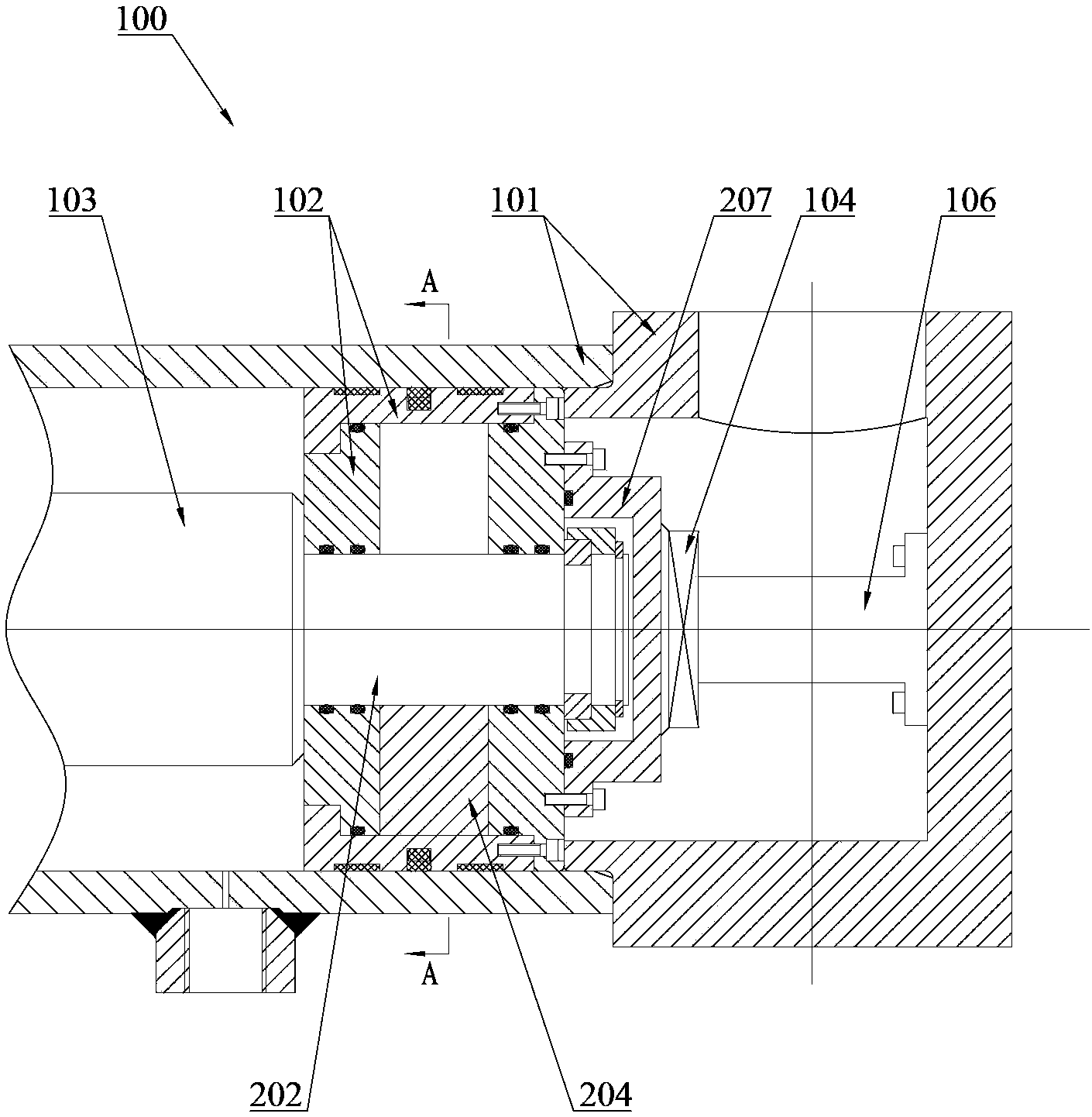

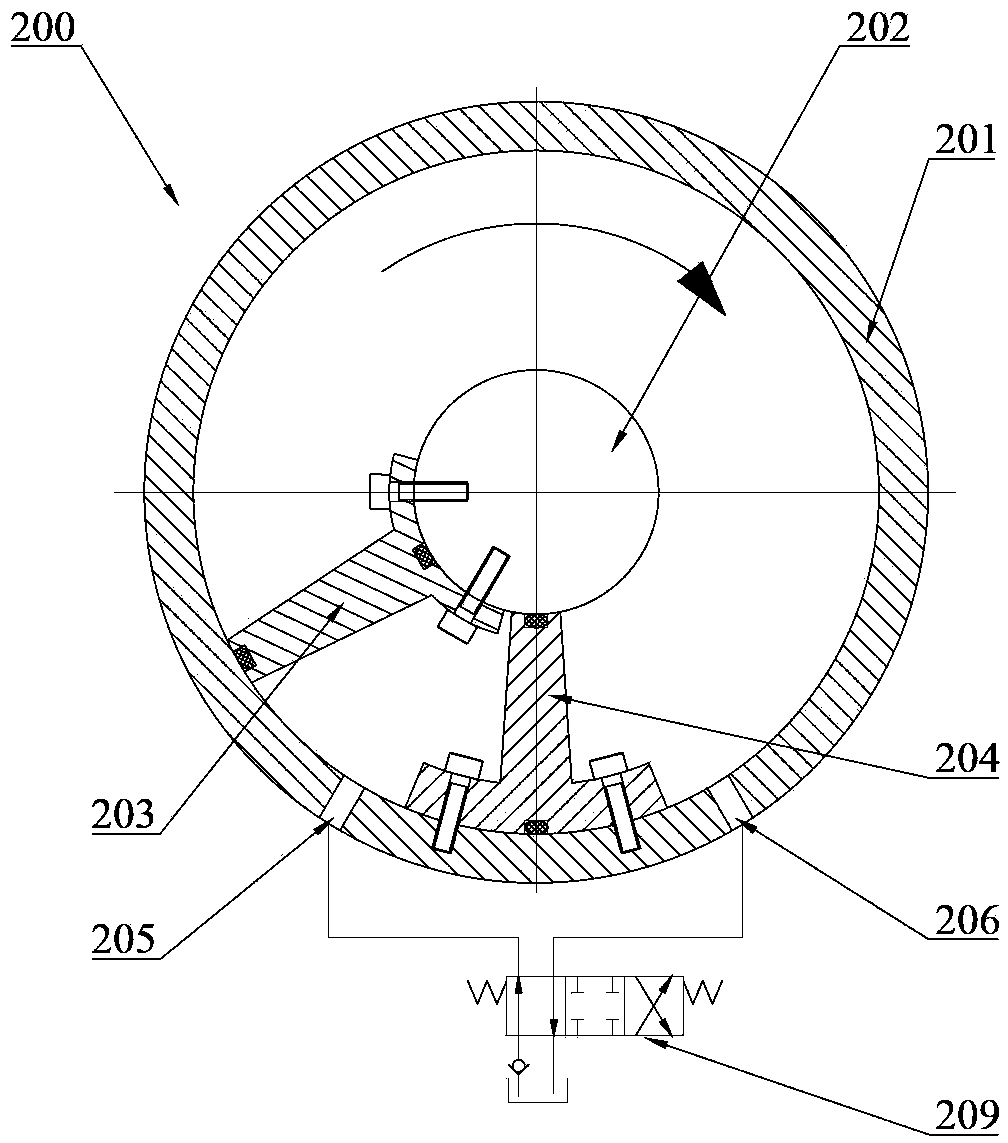

[0046] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0047] First of all, it needs to be explained that the orientation terms such as front and rear involved in the present invention refer to the direction of movement of the piston and piston rod of the pumping cylinder, specifically the direction in which the piston rod of the pumping cylinder pushes the concrete piston forward. , the reverse is the rear, and the related front, front, rear, and rear are all based on this.

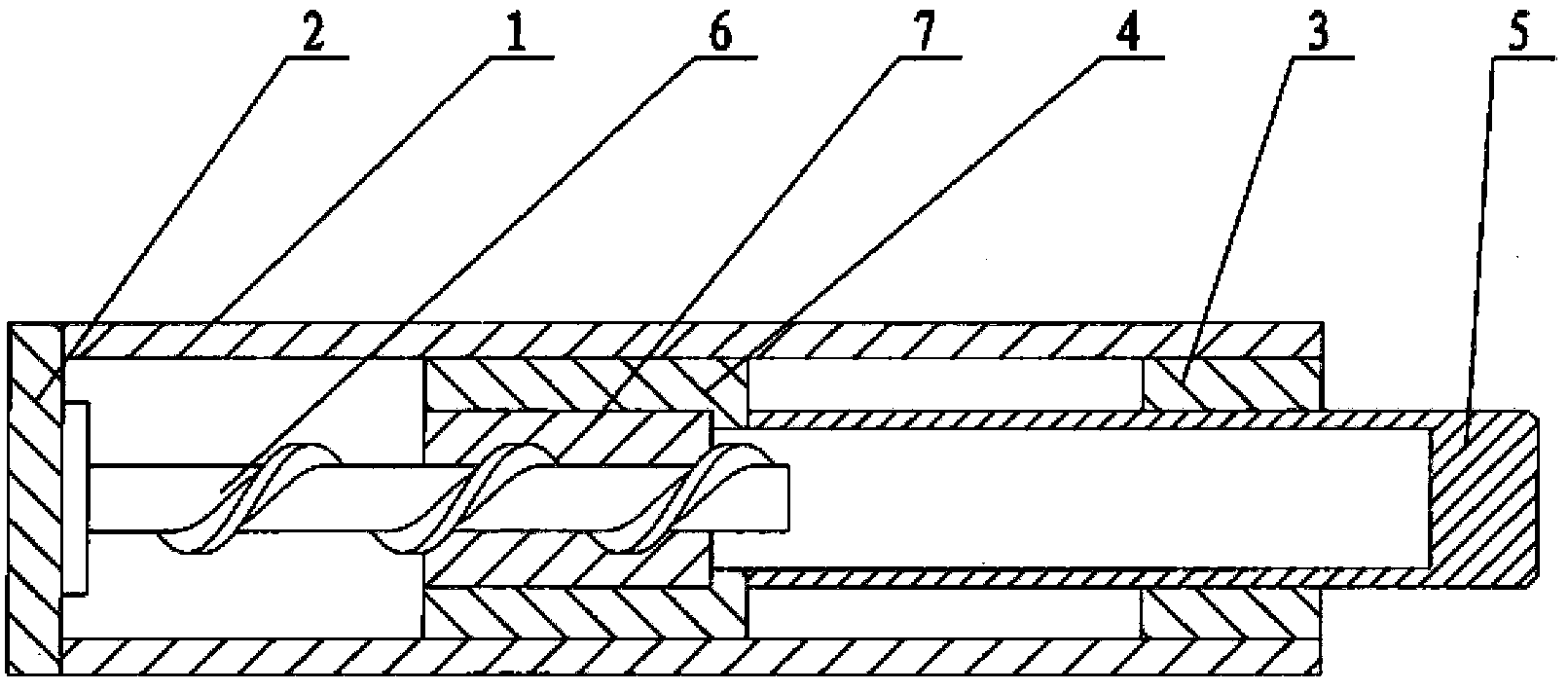

[0048]The basic design idea of the present invention is to provide a new type of pumping oil cylinder for the existing problem of the movement mode of the main oil cylinder piston rod in the existing pumping oil cylinder. The pumping oil cylinder has an independent driving de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com