Anti-inner-leakage device for stainless steel stop valve

A valve device, stainless steel technology, applied in the direction of valve device, lift valve, engine components, etc., can solve the problems of cost increase, air leakage, liquid leakage, waste, etc., and achieve the effect of easy replacement, long service life and low cost

Inactive Publication Date: 2014-01-22

石立军

View PDF6 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Stainless steel globe valve is an indispensable product widely used in industrial production and people's life, but in the process of use, due to acid and alkali corrosion, high temperature and low temperature, high pressure and long-term wear and tear, it will cause air leakage and liquid leakage. , if the stop valve is replaced with a new one, it will inevitably cause waste, and the cost of production and living will increase. If it is not replaced, it will cause waste of air leakage and liquid leakage. If it is repaired, it will cause damage to the stop valve and reduce its service life.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

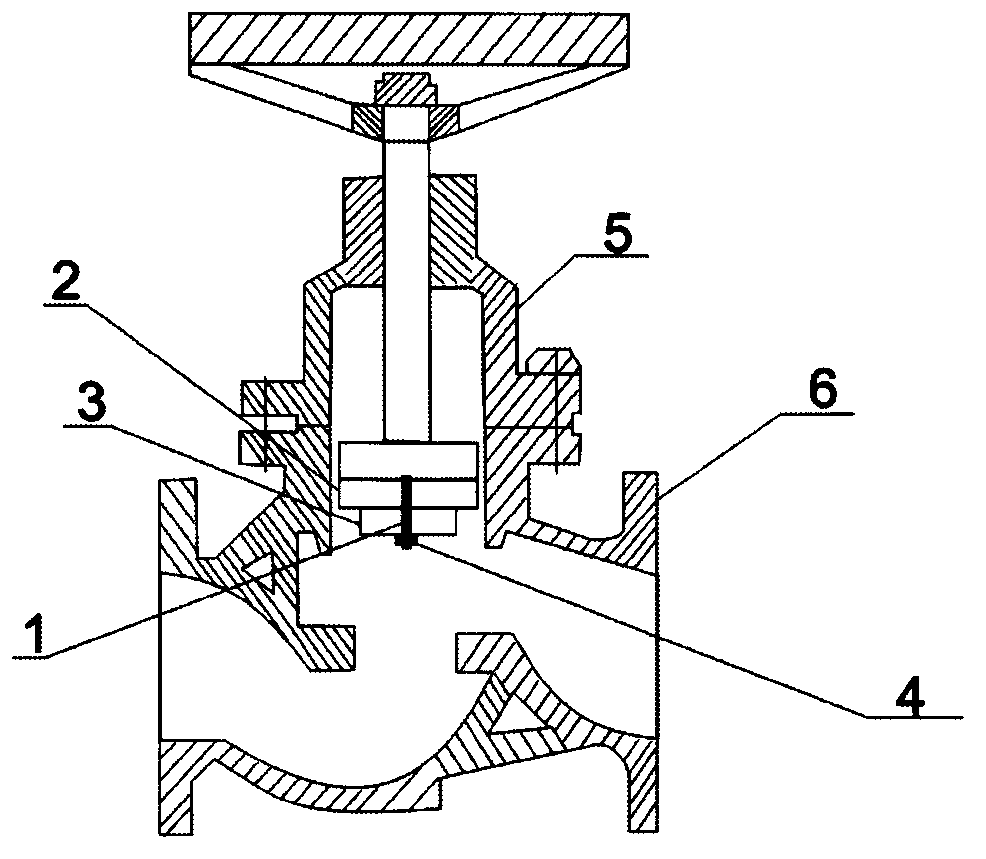

[0013] In this figure, the bolt 1 is fixed on the center of the sealing ring of the stop valve head 5, the polytetrafluoroethylene plate 2 is installed on the bolt 1, the stainless steel backing plate 3 is installed on the bolt 1 to press the polytetrafluoroethylene plate 2, and tightened with the nut 4, The installed shut-off valve head 5 is fixed on the shut-off valve body.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

An anti-inner-leakage device for a stainless steel stop valve is characterized by being formed by a stainless steel stop valve and a polytetrafluoroethylene plate. Due to the fact that a scrapped stainless steel stop valve with liquid leakage and gas leakage caused by an abraded face of the stop valve is adopted, and the technology that the polytetrafluoroethylene plate is added in the stop valve is adopted, the scrapped stainless steel stop valve recovers to be qualified. The scrapped stainless steel stop valve recovering to be qualified is good in use performance, free of gas leakage and liquid leakage and long in service life, improves valve utilization rate, and reduces the damage rate.

Description

(1) Technical field [0001] The invention belongs to a valve internal leakage prevention device, in particular to a stainless steel cut-off valve internal leakage prevention device (2) Background technology [0002] Stainless steel globe valve is an indispensable product widely used in industrial production and people's life, but in the process of use, due to acid and alkali corrosion, high temperature and low temperature, high pressure and long-term wear and tear, it will cause air leakage and liquid leakage. , If the stop valve is replaced with a new one, it will inevitably cause waste, and the cost of production and living will increase. If it is not replaced, it will cause waste of air leakage and liquid leakage. (3) Contents of the invention [0003] problem to be solved [0004] The purpose of the present invention is to overcome the deficiencies of the prior art, and to provide a stainless steel cut-off valve with long service life, corrosion resistance, high and lo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16K1/00F16K1/36

CPCF16K1/46F16K1/00F16K1/36

Inventor 石立军

Owner 石立军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com