Stay wire displacement encoder

A technology of displacement encoders and encoders, which is applied in the field of encoders, can solve the problems of inconvenient installation and debugging, large space occupation, and low production efficiency, and achieve the effects of compact structure, saving space, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

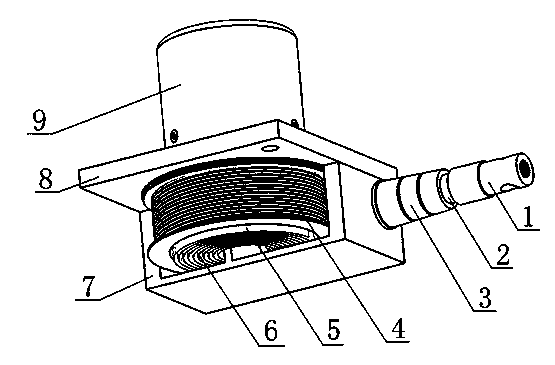

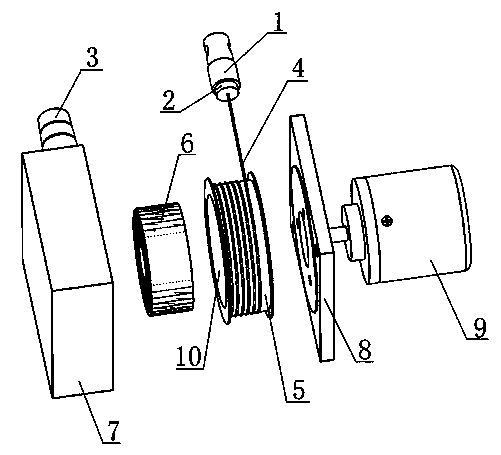

[0010] attached by figure 1 , 2 As shown: the sensor includes a pull ring 1, a shock absorbing ring 2, a pull wire lead column 3, a pull wire 4, a winding wheel 5, a coil spring 6, a wire coil spring box 7, an encoder support 8, and an encoder body 9; The encoder main body 9 is arranged on the top of the encoder support 8, and the coil spring box 7 below the encoder support 8 is sequentially provided with a winding wheel 5 and a coil spring 6, and the winding wheel 5 A backguy 4 is wound on it, and one end of the backguy 4 is provided with a pull ring 1 and a shock absorbing ring 2. The inside of the reel 5 has a coil spring chamber 10, and the coil spring 6 is arranged in the coil spring chamber 10. There is a backguy lead post 3 on the above-mentioned winding spring box 7 .

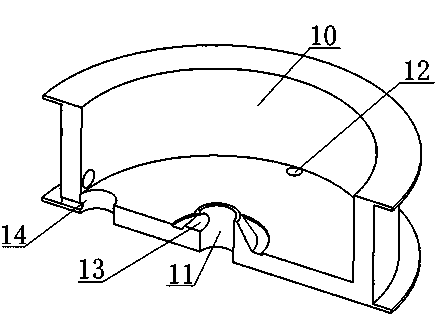

[0011] attached by image 3 As shown: the coil spring chamber 10 is a semi-closed structure, and the closed end is provided with a central hole 11 connecting the encoder body 9, a coil spring column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com