Force measurement tensioning device for steel structural stay rope

A steel structure and force measurement technology, which is applied in the direction of tension measurement, etc., can solve the problems of inaccurate tension, inability to accurately reflect the internal tension of steel structure cables, and inability to accurately reflect the axial internal force of cables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

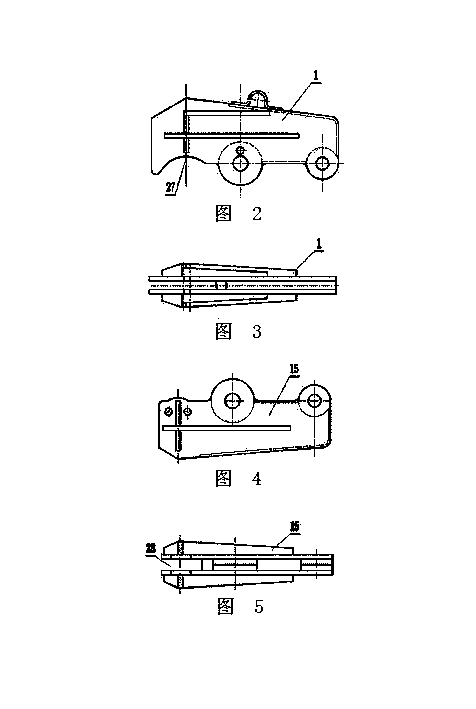

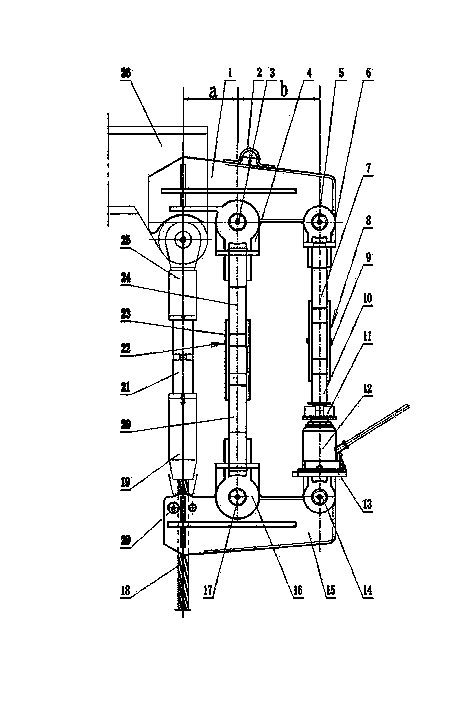

[0023] exist figure 1 In the shown steel structure cable force measuring tensioner, the upper end of the connecting rod 22 is hinged to the middle position of the upper force applying lever 1 through the connecting rod upper pin seat 5 and the connecting rod upper pin 3, and the lower end of the connecting rod 22 passes through The lower pin seat 16 of the connecting rod and the lower pin 17 of the connecting rod are hinged at the middle position of the lower applying lever 15 . The connecting rod 22 comprises an upper connecting rod screw 24, a connecting rod adjusting coil 23 and a lower connecting rod screw 20. The upper connecting rod screw 24 is fixedly connected to the upper pin seat 4 of the connecting rod, and the lower connecting rod screw 20 is fixedly connected to the lower connecting rod. On the pin seat 16, the outer ends of the upper connecting rod screw 24 and the lower connecting rod screw 20 are respectively screwed to the two ends of the connecting rod adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com