Ultrasonic automatic detection system and detection method of workpiece with clearance gridding-shaped multi-slope curve surfaces

A surface workpiece, automatic detection technology, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, measuring devices, etc., to achieve accurate and reliable inspection results, high degree of automation, human-computer interaction interface friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

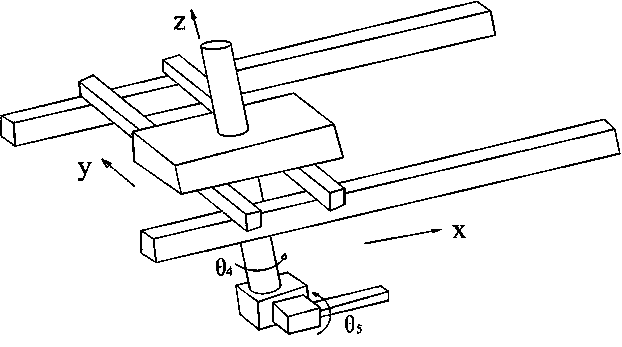

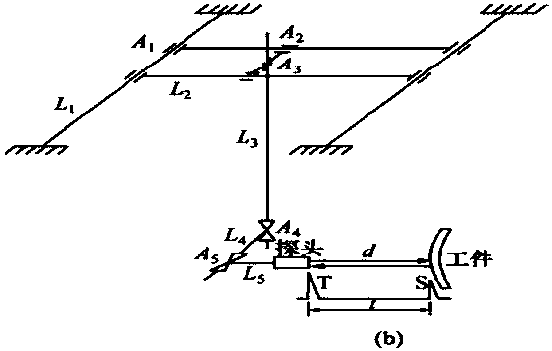

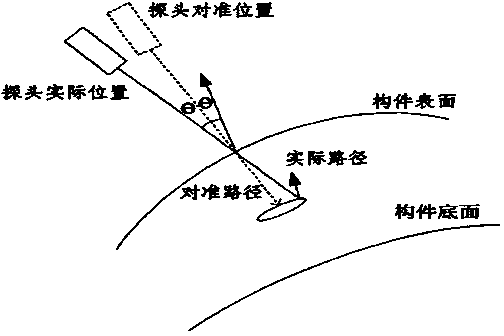

[0065] Such as figure 1 As shown, the ultrasonic automatic detection system of the present invention has a grid-shaped multi-slope curved surface workpiece with gaps, including an ultrasonic flaw detector, the probe of which is installed on a five-degree-of-freedom scanning bracket, and also includes a scanner and an industrial computer, wherein Degree of freedom scanning bracket: It has three linear degrees of freedom of X, Y, and Z, and two rotational degrees of freedom of A and B. Its three linear degrees of freedom of X, Y, and Z, and two rotational degrees of freedom of A and B pass through Driven by an independent motor, the five-degree-of-freedom motor is controlled by an industrial computer; scanner: used to scan the surface parameters of the workpiece to be measured, and transmit the surface parameters to the industrial computer; industrial computer: receive the measured workpiece transmitted by the scanner surface parameters, and convert the surface parameters into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com