Method for locating inter-strand short circuit fault point of transposed conductor and special locating device

A technology for transposing conductors and short-circuit faults, applied in directions such as fault locations, can solve the problems of inability to locate short-circuit points, inconvenient repairs, and large positioning errors, and achieve the effect of improving detection efficiency, avoiding inaccurate positioning, and high positioning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

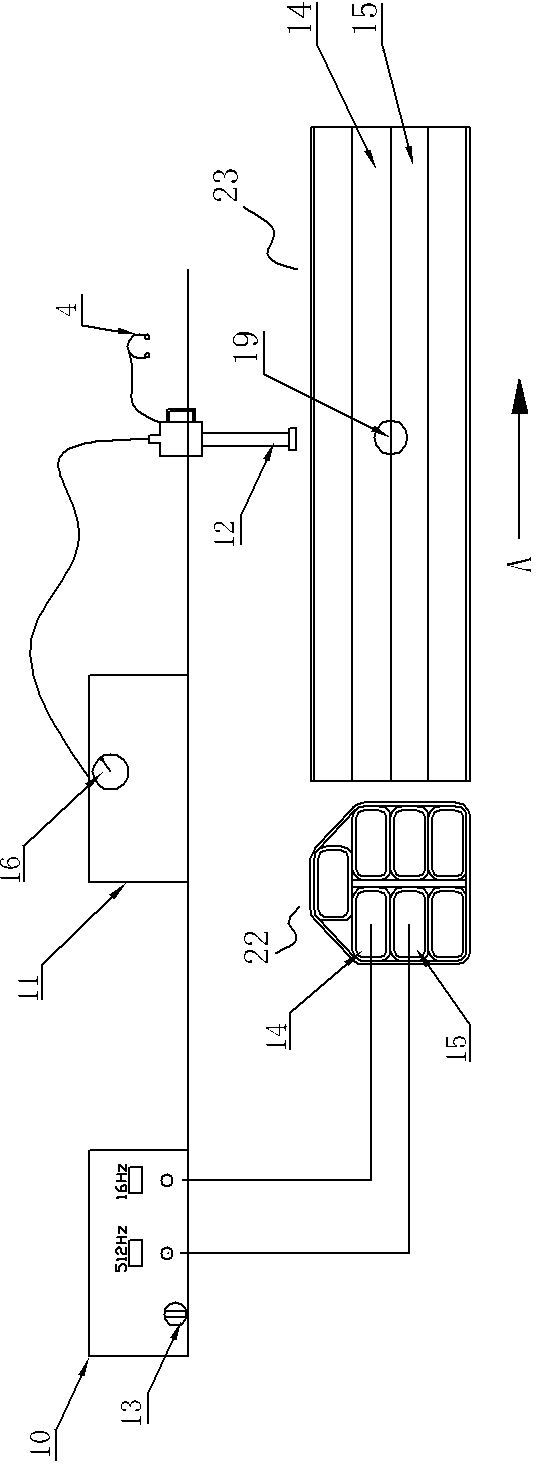

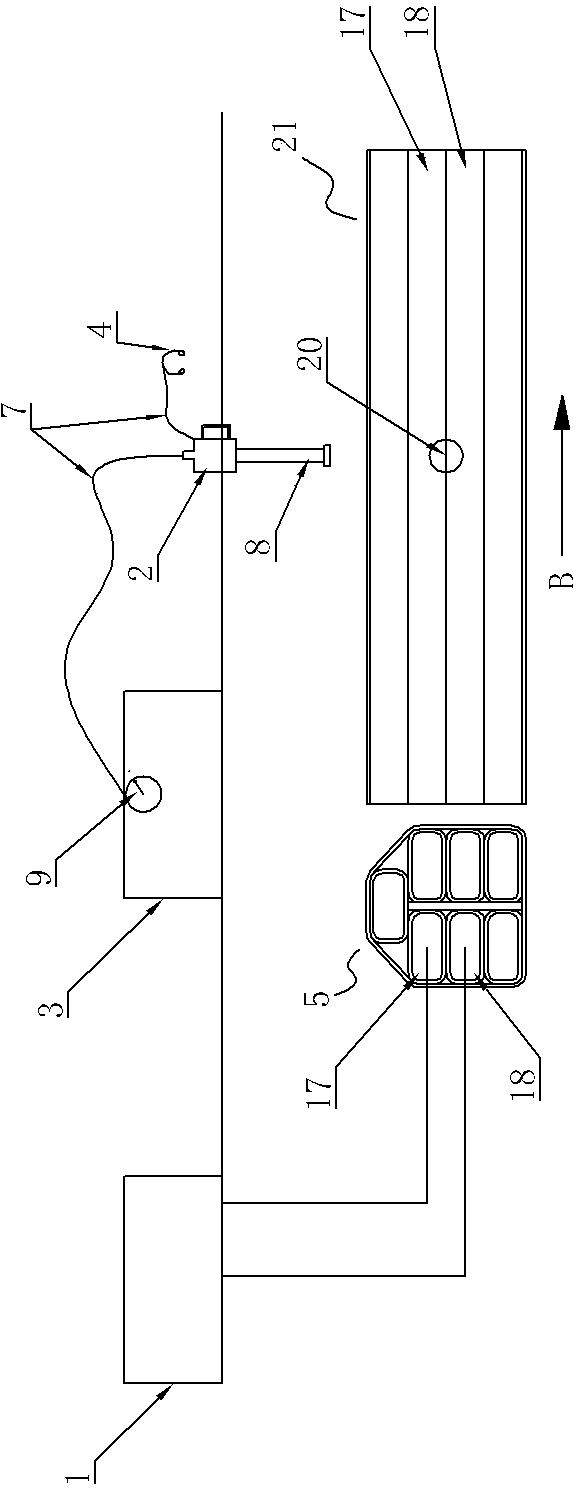

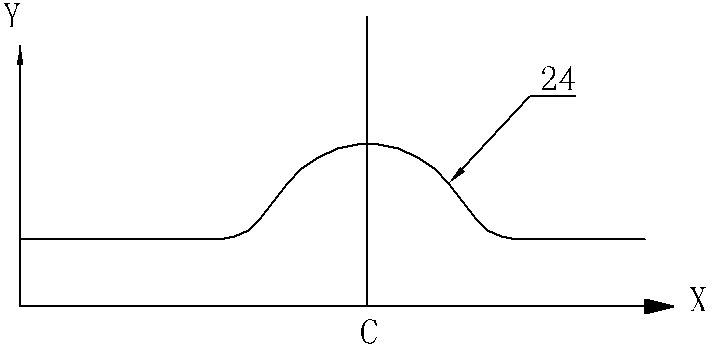

[0020] See figure 2 , a method for fixing the short-circuit fault point between strands of a transposed wire. Firstly, the acoustic wave signal receiver 3 and the earphone 4 are respectively connected to the acoustic wave detector 2 with a wire 7. Apply AC500V impact high voltage between the faulty enameled wires 17 and 18 between the 5 strands of the transposition wire to make the fault click through and generate a flashover discharge. The inspector can hear the rhythmic and continuous discharge of "crack...crack...crack..." through the earphone 4 Sound, put the sound wave pickup probe 8 of the sound wave detector 2 on the top of the transposition wire 5 to be tested and move slowly and uniformly along the direction of the transposition wire to be tested, observe the swing of the display pointer 9 of the sound wave signal receiver 3 and listen to the inside of the earphone 4 Observe the swinging range of the pointer while moving, and find the part with the largest swinging r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com