Electromagnetic Wire Vibration Reduction Device for Laser Caliper

A technology of laser diameter measuring instrument and vibration damping device, which is applied in the manufacture of circuits, electrical components, cables/conductors, etc., and can solve the problems of inconvenient adjustment and poor adjustment accuracy of vibration damping devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

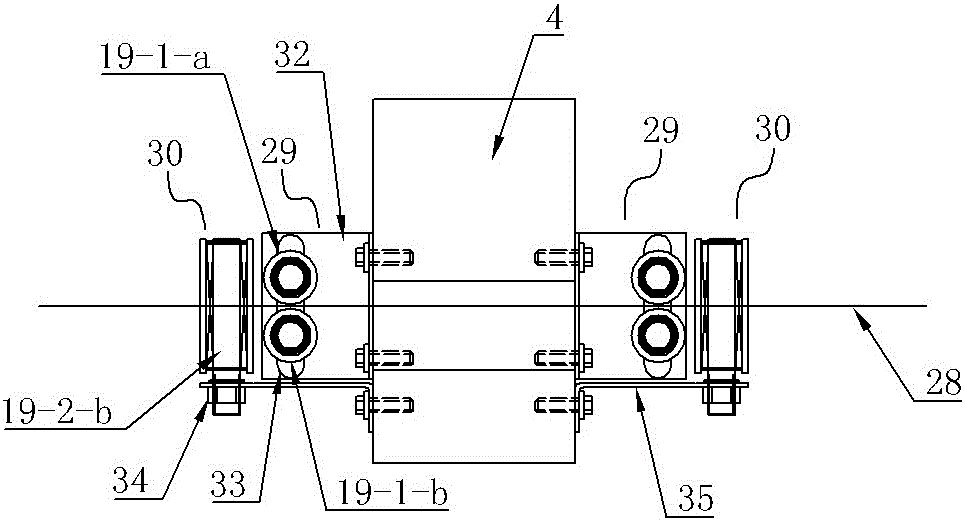

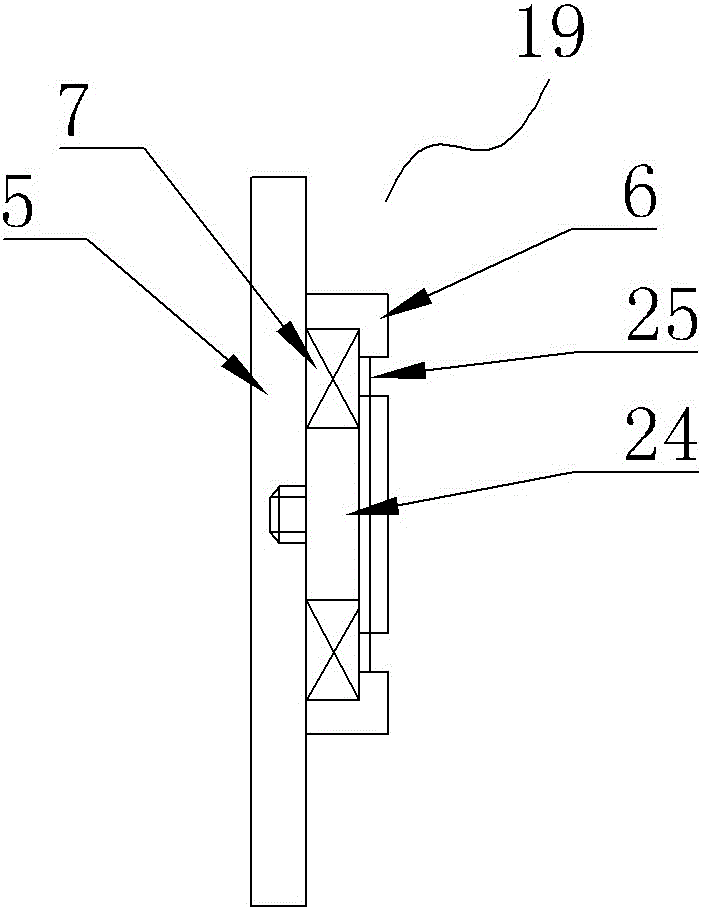

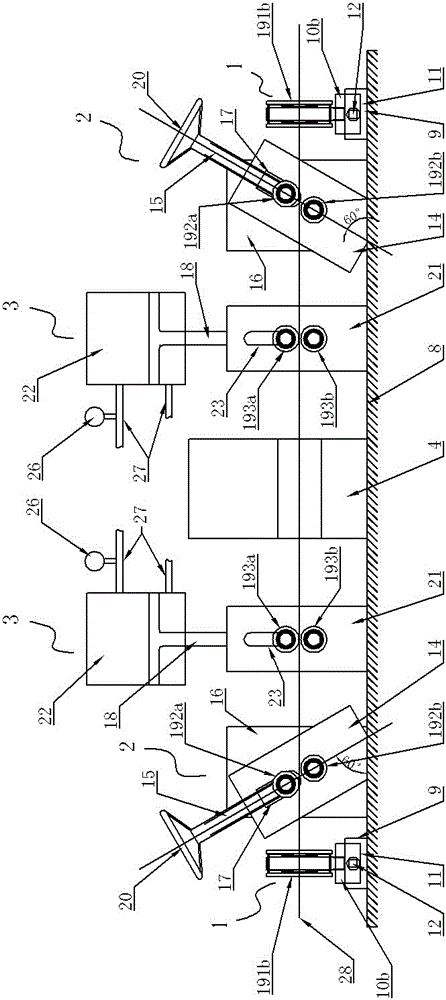

[0005] See figure 2 , image 3 , Figure 4 , Figure 5 , the device of the present invention includes an amplitude vibration damping device 1 and an axial vibration damping device 2, the amplitude vibration damping device 1 and the axial vibration damping device 2 both include two groups, and the incoming line end and the outgoing line end of the laser caliper 4 are respectively A group of axial vibration damping devices 2 are installed, and each group of axial vibration damping devices 2 is equipped with a group of amplitude vibration damping devices 1 on the side far away from the laser side diameter gauge 4. The amplitude vibration damping devices 1, axial vibration damping The vibration device 2 is respectively provided with two roller modules, the two roller modules 192a, 192b of the axial vibration damping device 2, and the two roller modules 191a, 191b of the amplitude vibration damping device 1 are respectively arranged along the axial ends of the electromagnetic wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com