Anti-collision device of welding robot

A collision device and welding machine technology, which is applied to the field of welding robot devices and welding robot anti-collision devices, can solve the problems of lack of versatility and automatic recovery, avoid recalibration or programming, and improve safety And stability, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

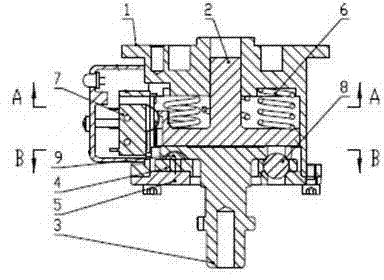

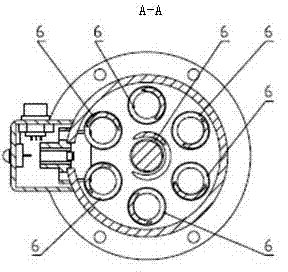

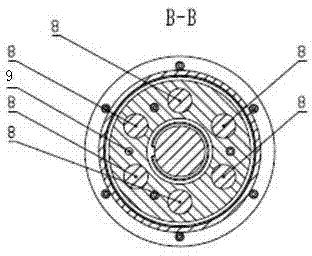

[0018] Such as Figures 1 to 3 As shown, the present invention includes a base 1 connected with the execution end of the robot, and a connecting shaft 3 connected with the top end of the welding torch. A through hole is provided in the center of the base 1 . Between the base 1 and the connecting shaft 3, a disc-shaped spring fixed disk 2 with a central protrusion is arranged, and its lower end surface fits with the upper end surface of the connecting shaft 3, and its protrusion extends into the through hole of the base 1 Inside, a plurality of springs 6 in a compressed state are installed on the protrusion and its surrounding disc surface. The springs around the protrusion are evenly distributed on the spring fixing plate 2 . One side of the spring fixed plate 2 is provided with a fulcrum, and the fulcrum is in contact with the sensor 7 installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com