Roll Surface Treatment Units for Crystallizers

A processing device and crystallizer technology, which is applied in the direction of machine tools, grinders, metal processing equipment, etc. designed for grinding the rotating surface of workpieces, to achieve the effect of improving the quality and uniformity of strip making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

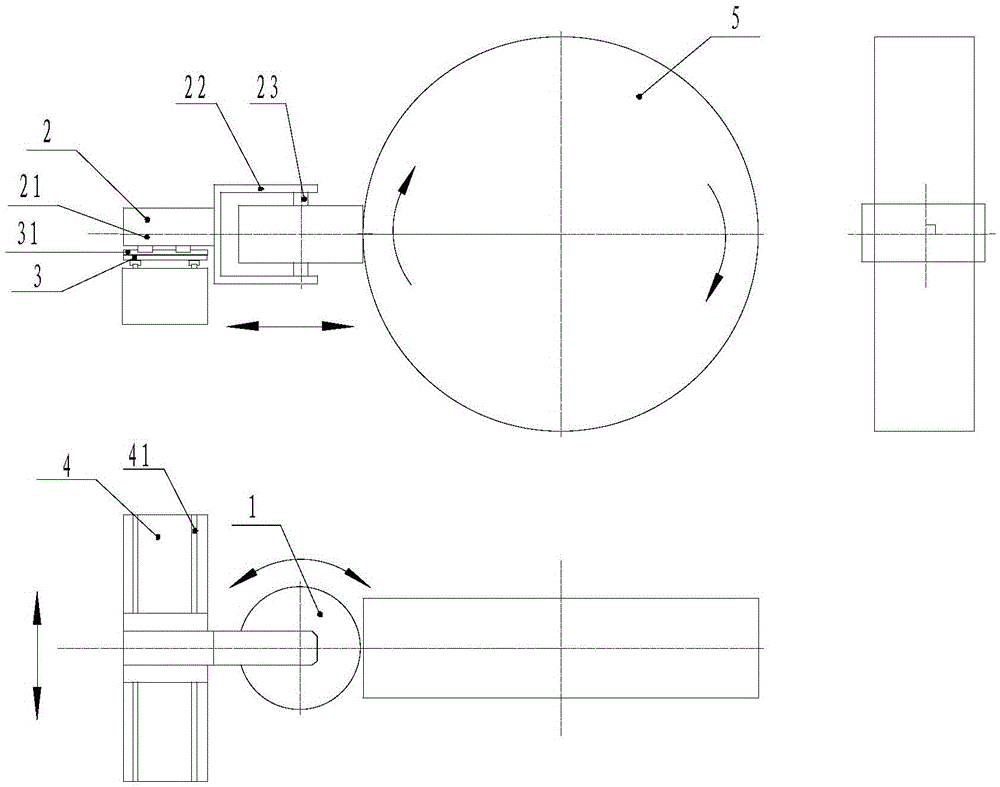

[0018] Below to figure 1 As an example, the roll surface treatment device for the crystallizer of the embodiment of the present invention will be described in detail.

[0019] figure 1 The schematic diagram of the roller surface treatment device for the crystallizer provided by the embodiment of the present invention, wherein the left figure is the main view, the right figure is the side view from the direction of the guide rail platform, and the bottom figure is the top view. Such as figure 1 As shown, the device includes: a grinding wheel 1 , a fixed frame 2 , a slide plate 3 and a rail platform 4 . This roller surface treatment device for a crystallizer treats the surface of the crystallizer 5 shown in the figure.

[0020] specific,

[0021] The slide plate 3 reciprocates along the rail platform 4;

[0022] The fixed frame 2 is connected with the guide rail of the slide plate 3, and moves forward and backward along the guide rail;

[0023] The fixed frame 2 includes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com