Novel embossing roller

An embossing roller, a new type of technology, applied in the direction of mechanical processing/deformation, etc., can solve the problems of local ambiguity, poor uniformity, uneven pattern depth, etc., to achieve strong and uniform force, ideal embossing effect, and beautiful patterns Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

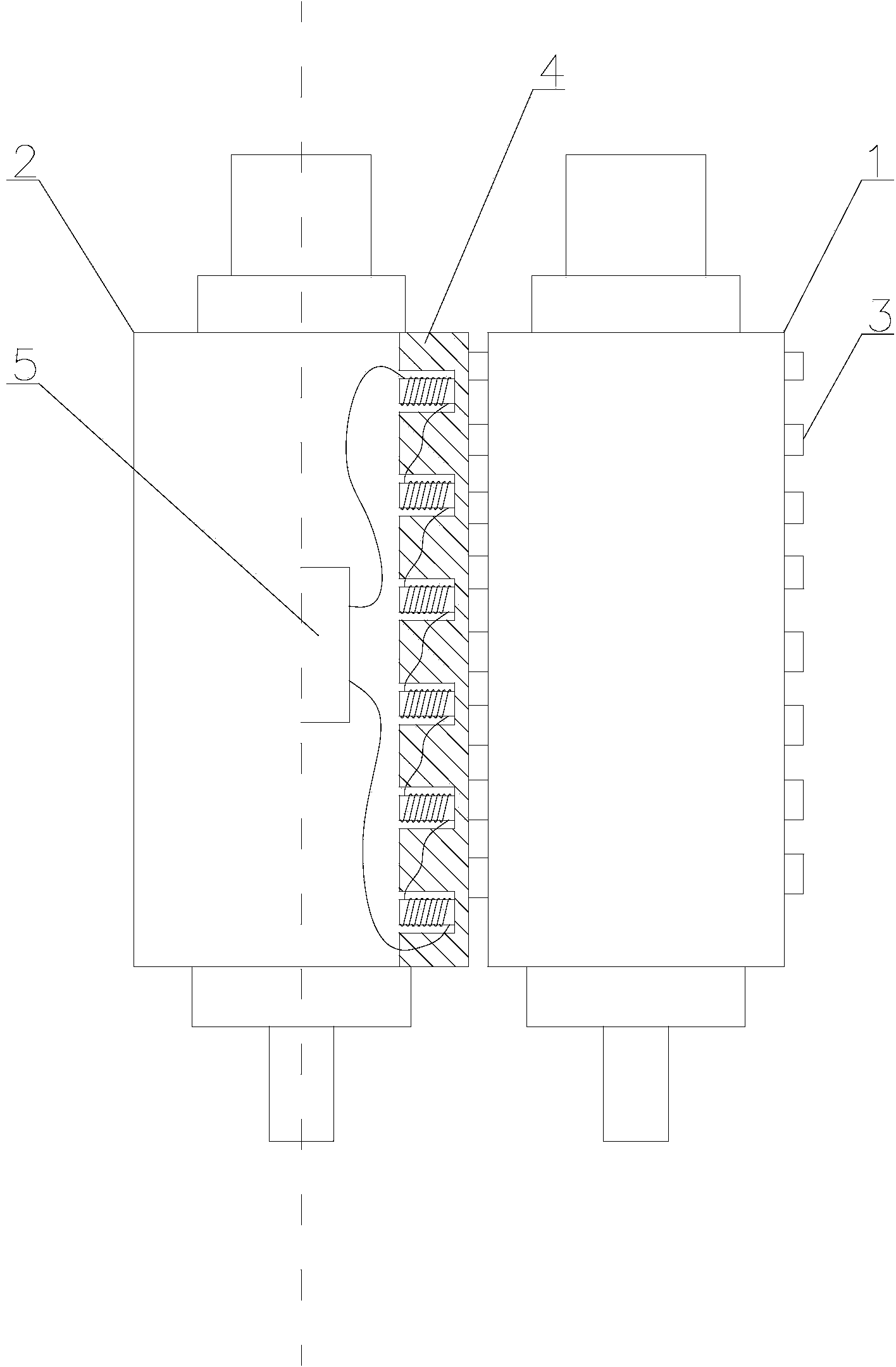

[0010] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0011] like figure 1 As shown, the present invention provides a novel embossing roll, comprising an upper roll 1 and a lower roll 2, the upper roll 1 is engraved with embossed lines 3, the lower roll 2 is a composite smooth roll, and the lower roll 2 includes a cylinder 4, the cylinder The material of the body 4 is alloy steel, and a plurality of annular grooves are opened from the inner wall to the outer wall of the cylinder body 4. The depth of the annular grooves is smaller than the wall thickness of the cylinder body 4, and multiple coils are wound on the inner wall of each annular groove. The coils are all connected with the external circuit 5 .

[0012...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap