Low-VOC sponge as well as preparation method and application thereof

A sponge and nanoparticle technology, applied in chemical instruments and methods, layered products, transportation and packaging, etc., can solve the problems of limiting the use of polyurethane foam, achieve uneven hardness, good recyclable catalytic effect, and reduce VOC content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

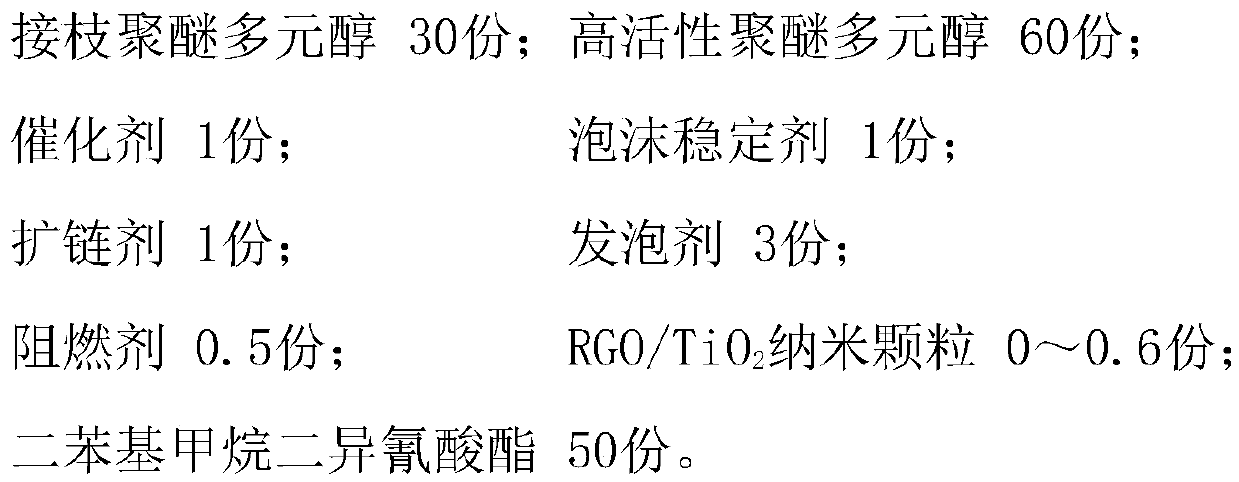

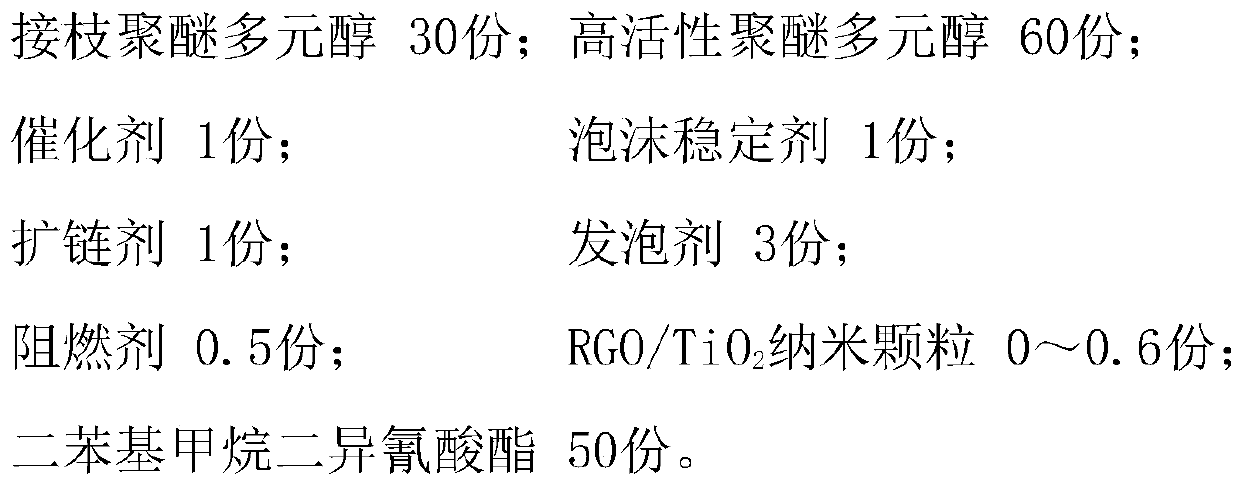

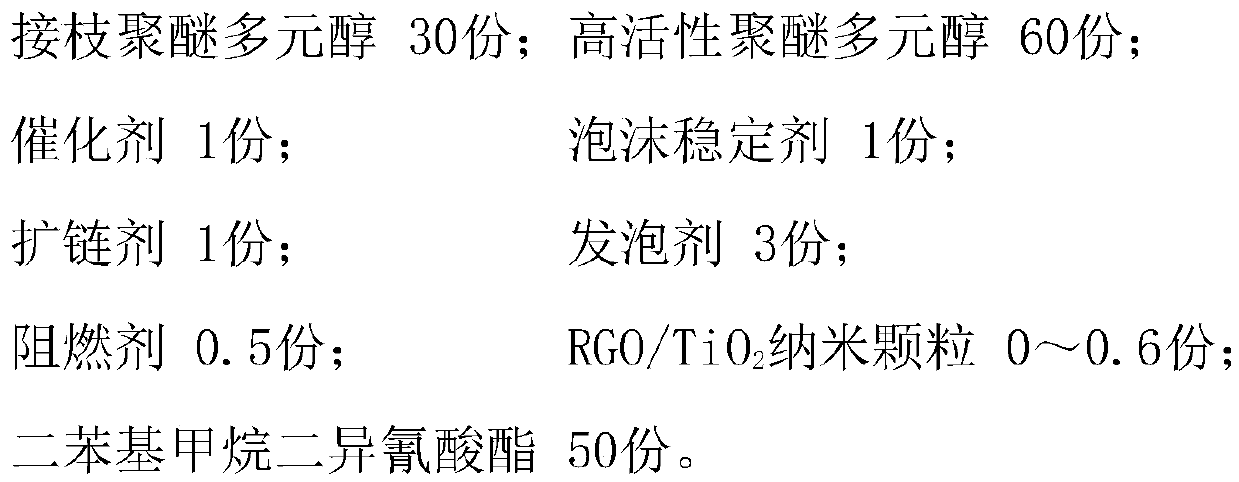

[0031] The preparation method of low VOC sponge, comprises the following steps:

[0032] Ⅰ. Preparation of RGO / TiO 2 Nanoparticles: Add 10 to 50 parts of graphene oxide to the mixed solution of ethanol and deionized water for 30 minutes of ultrasonic vibration, then transfer the mixed solution to a hydrothermal kettle, and divide 50 parts of TiO 2 Pour the powder into a hydrothermal kettle and stir at high speed for 10 minutes; raise the temperature to 120°C and stir for 3 hours; after the reaction, wash the final product with ethanol and deionized water until neutral, and finally dry it at 80°C to obtain RGO / TiO 2 nanoparticles;

[0033] Ⅱ. Mix 30 parts of grafted polyether polyol, 60 parts of high activity polyether polyol, 1 part of catalyst, 1 part of foam stabilizer, 1 part of chain extender, 3 parts of blowing agent, 0.5 part of flame retardant, 0 ~0.6 part RGO / TiO 2 Add nanoparticles and water into the reaction kettle, stir ultrasonically for 30 minutes, and config...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com