System for manufacturing ultra-thin glass

A technology for manufacturing systems and ultra-thin glass, which is applied in semiconductor/solid-state device manufacturing, optics, instruments, etc. It can solve problems such as breakage, deformation of glass 20, and failure to apply to glass 20, so as to achieve the effect of saving usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

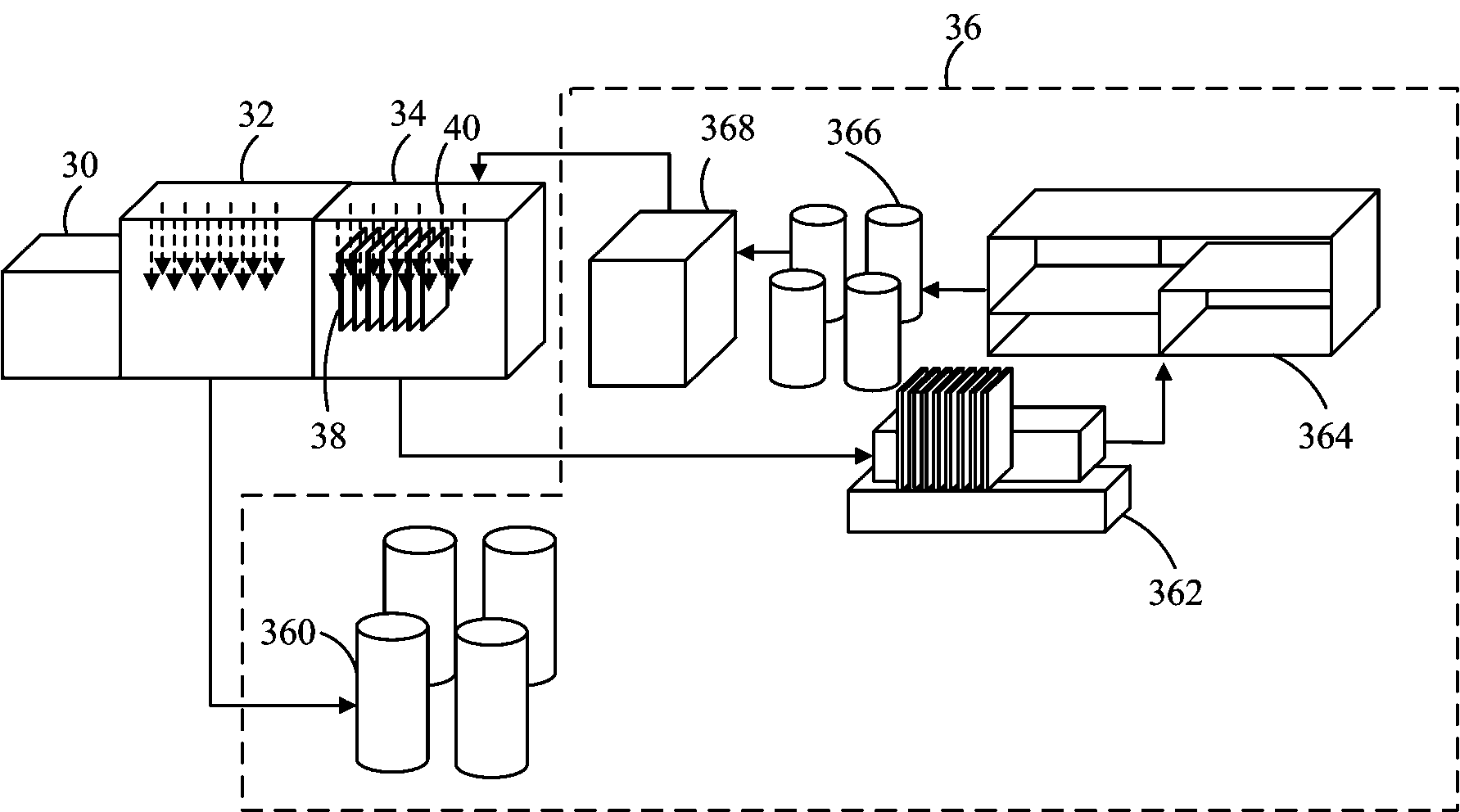

[0034] The specific implementation of the ultra-thin glass manufacturing system provided by the present invention will be described in detail below with reference to the accompanying drawings.

[0035] Please refer to the attached image 3 , a schematic diagram of an ultra-thin glass manufacturing system according to an embodiment of the present invention.

[0036] The ultra-thin glass manufacturing system includes a loading unit 30 , a cleaning unit 32 , an etching unit 34 and a recycling unit 36 .

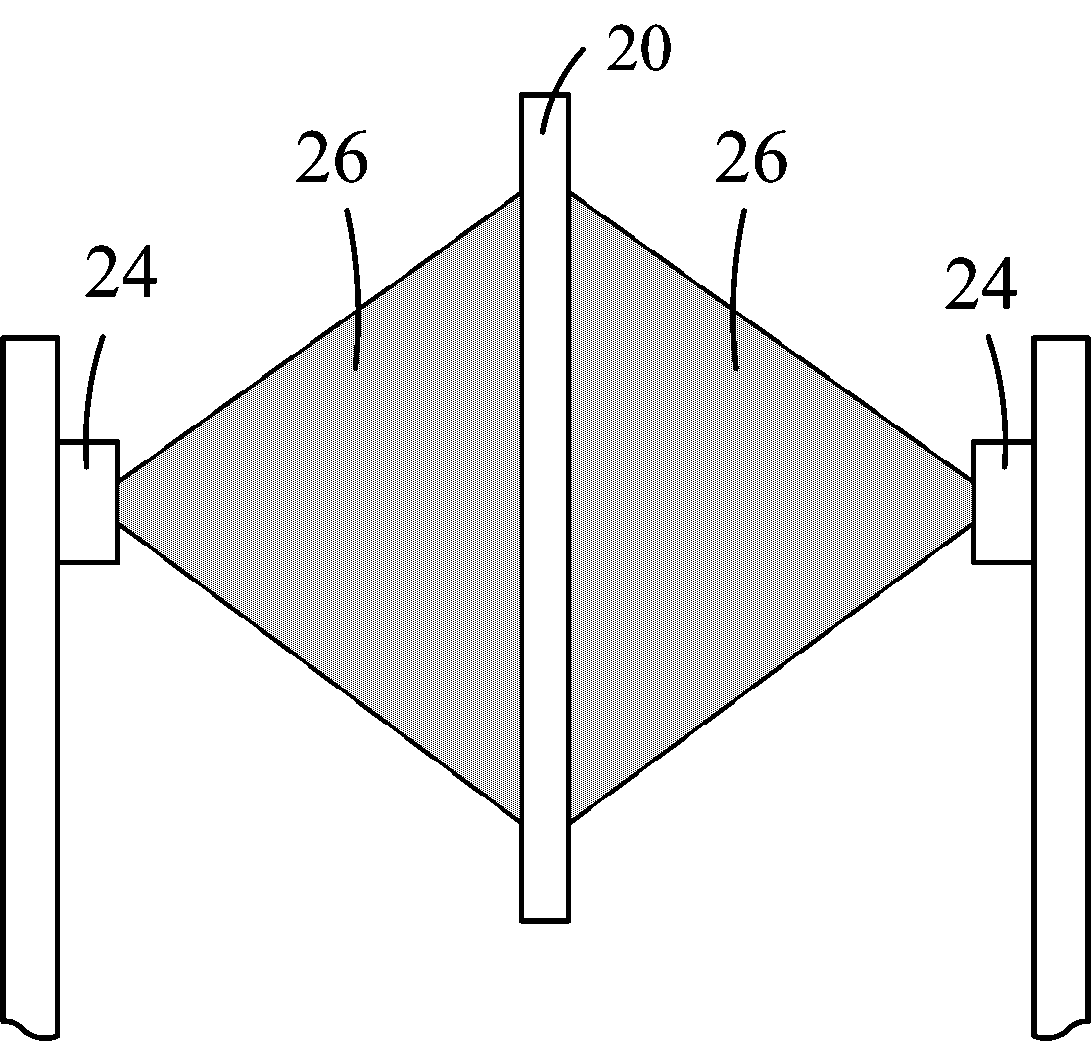

[0037] The loading unit 30 can be regarded as a preparation stage, at least one glass 38 (as shown inside the etching unit 34) is first fixed to a vertical standing state and placed in the loading unit 30, generally speaking, the thickness of the glass 38 is about greater than 1.5 mm (millimeter; mm).

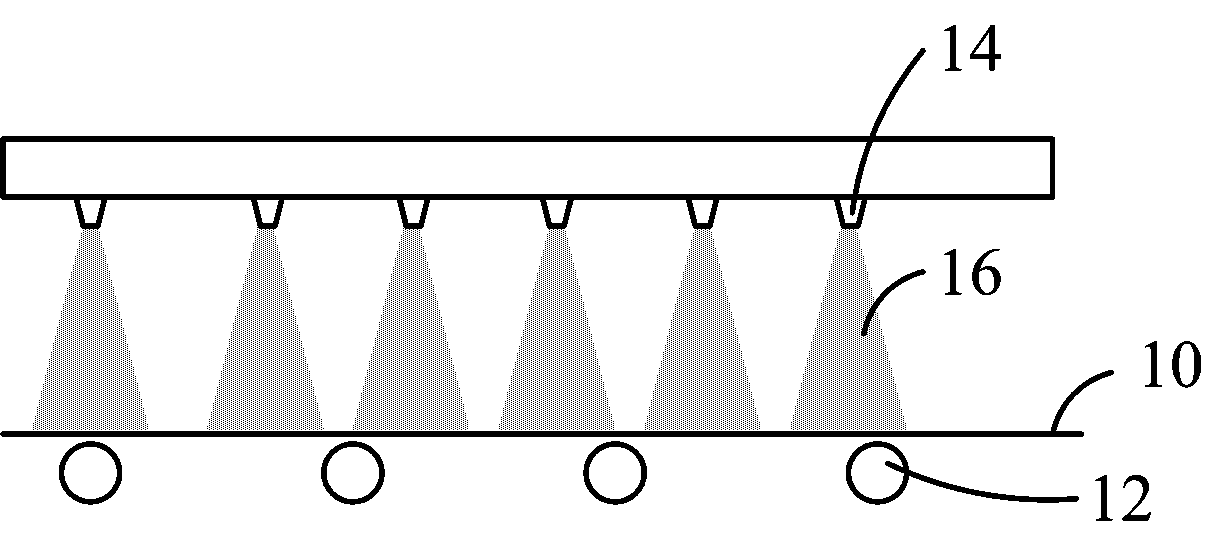

[0038] When the glass 38 is transported to the cleaning unit 32 , the cleaning unit 32 sprays neutral liquid and / or clean pure water on the glass 38 to perform neutralization ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com