Al-V-B intermediate alloy as well as preparation method and application thereof

A master alloy, al-v-b technology, applied in the field of metal materials, can solve problems such as failure to meet higher requirements for grain refiners, adhesion and settlement of salt melt mixtures, uneven composition of master alloys, etc., to achieve shortening The effect of melting time, uniform refining effect and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

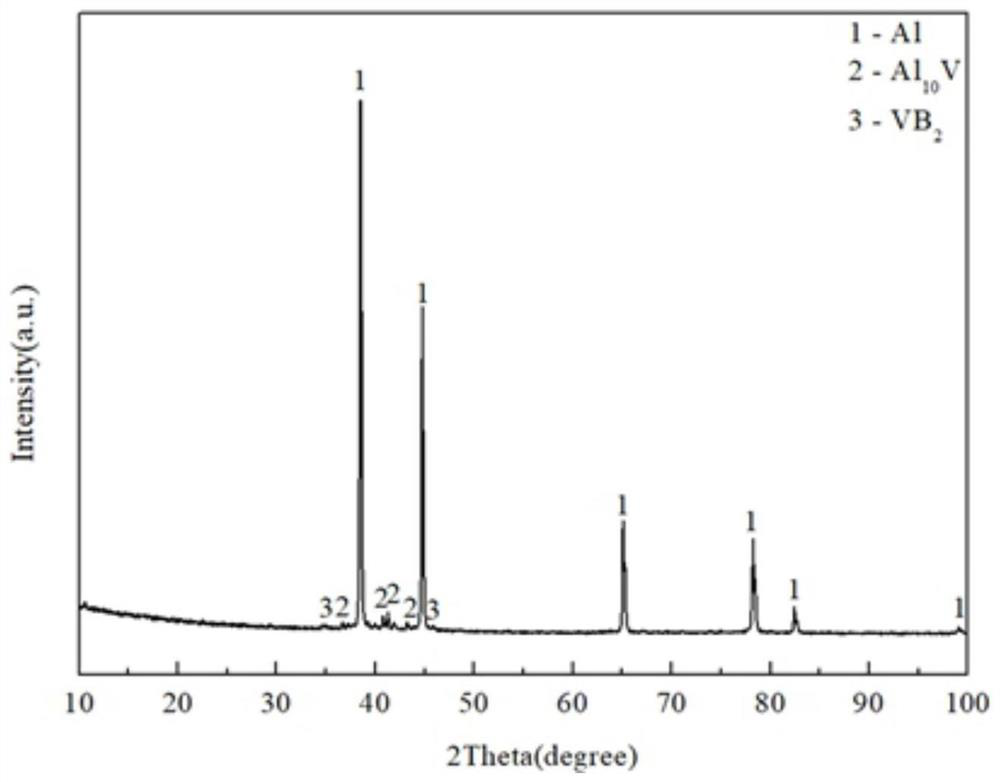

[0045] An Al-V-B master alloy, the composition of chemical elements is by mass percentage, V: 2%, B: 1%, and the balance is Al; the Al-V-B master alloy is an Al-2V-1B master alloy;

[0046] A kind of preparation method of Al-V-B master alloy, comprises the steps:

[0047]Step 1: Weigh AlV according to the mass ratio of Al-V-B master alloy 5 Block and KBF 4 powder, then AlV 5 Block and KBF 4 The powder is wrapped with aluminum foil and mixed, heated to 140°C and dried for 2 hours to remove moisture;

[0048] Step 2: Preheat the crucible to 320°C in a heating furnace, then place pure aluminum in the crucible, and heat until the pure aluminum is completely melted to form an aluminum melt; then wrap the AlV 5 Block and KBF 4 The powdered aluminum foil is immersed in the aluminum melt, and after it is completely melted, it is stirred until it is evenly mixed to form a mixed melt; at this time, the components in the mixed melt are V: 2%, B: 1%, and the balance is Al;

[0049] ...

Embodiment 2

[0063] An Al-V-B master alloy, the composition of chemical elements is by mass percentage, V: 2%, B: 2%, and the balance is Al; the Al-V-B master alloy is an Al-2V-2B master alloy;

[0064] A kind of preparation method of Al-V-B master alloy, comprises the steps:

[0065] Step 1: Weigh AlV according to the mass ratio of Al-V-B master alloy 5 Block and KBF 4 powder, then AlV 5 Block and KBF 4 The powder is wrapped with aluminum foil and mixed, heated to 145°C and dried for 2.5 hours to remove moisture;

[0066] Step 2: Preheat the crucible to 330°C in a heating furnace, then place pure aluminum in the crucible, and heat until the pure aluminum is completely melted to form an aluminum melt; then wrap the AlV 5 Block and KBF 4 The powdered aluminum foil is immersed in the aluminum melt, and after it is completely melted, it is stirred until it is evenly mixed to form a mixed melt; at this time, the components in the mixed melt are V: 2%, B: 2% by mass, and the balance is Al;...

Embodiment 3

[0080] An Al-V-B master alloy, the composition of chemical elements is by mass percentage, V: 3%, B: 1%, and the balance is Al; the Al-V-B master alloy is an Al-3V-1B master alloy;

[0081] A kind of preparation method of Al-V-B master alloy, comprises the steps:

[0082] Step 1: Weigh AlV according to the mass ratio of Al-V-B master alloy 5 Block and KBF 4 powder, then AlV 5 Block and KBF 4 The powder is wrapped with aluminum foil and mixed, heated to 135°C and dried for 3 hours to remove moisture;

[0083] Step 2: Preheat the crucible to 310°C in a heating furnace, then place pure aluminum in the crucible, and heat until the pure aluminum is completely melted to form an aluminum melt; then wrap the AlV 5 Block and KBF 4 The powdered aluminum foil is immersed in the aluminum melt, and after it is completely melted, it is stirred until it is evenly mixed to form a mixed melt; at this time, the components in the mixed melt are V: 3%, B: 1%, and the balance is Al;

[0084]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com