Method for extracting ursodesoxycholic acid

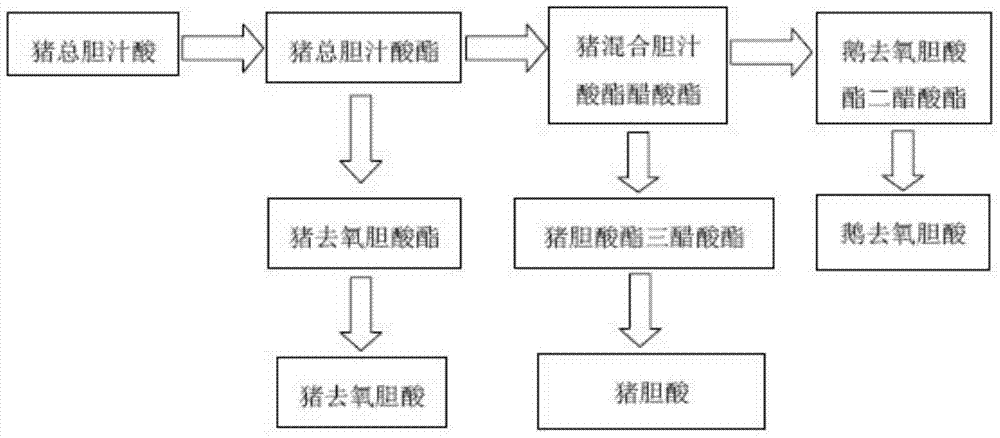

A technology of ursodeoxycholic acid and an extraction method, which is applied in the field of extraction of ursodeoxycholic acid, can solve the problems of many reaction steps, complicated processes, difficulty in large-scale production and the like, and achieves the effect of reducing the preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Take a 250ml round bottom flask, add 10g of crude porcine total bile acid, 50ml of anhydrous methanol, 0.7ml of 98% concentrated sulfuric acid, stir and react at room temperature for 24h, the reaction is completed after TLC detection, and stop the reaction after no raw materials remain. Add anhydrous NaHCO to the system 3 Adjust the pH of the solid to neutral, filter off the inorganic salts, wash the filter cake with methanol, combine the filtrate and lotion, and recover the methanol under reduced pressure to obtain a tan viscous substance, add 50ml of water to dissolve the remaining inorganic salts, and then divide it with ether. Extract the organic matter (50ml, 30ml, 20ml) for the second time, combine the organic phases, and wash with saturated NaHCO 3 solution and saturated brine for 1 wash, anhydrous Na 2 SO 4 Dry for 2 hours, filter, distill off ether under reduced pressure to obtain 11.4 g of brown viscous substance, add 30 ml of benzene into the flask, dis...

Embodiment 2

[0038] Compared with Example 1, the steps (1), (2), (3) and (4) are the same, and the steps (5) and (6) are as follows:

[0039] (5) Combine the mother liquor obtained from the extraction of methyl hyocholic acid triacetate and the recrystallized mother liquor, and remove the solvent under reduced pressure to obtain 6.3 g of a tan viscous substance, at this time, the main component of which is methyl chenodeoxycholic acid For diacetate, add 50ml of methanol into the flask, raise the temperature to 65°C and stop heating after the viscous matter is completely dissolved. After the system naturally cools down to room temperature, let it stand in the refrigerator for 96h, and a pale yellow solid precipitates. Filter and filter the cake with ice-cold methanol After washing and drying, 2.4 g of a light yellow powder was obtained, which was recrystallized from methanol, and the solid was dried under an infrared lamp to constant weight to obtain 2.1 g of a white powder, mp 111-113°C, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com