Preparation method of timosaponin A III

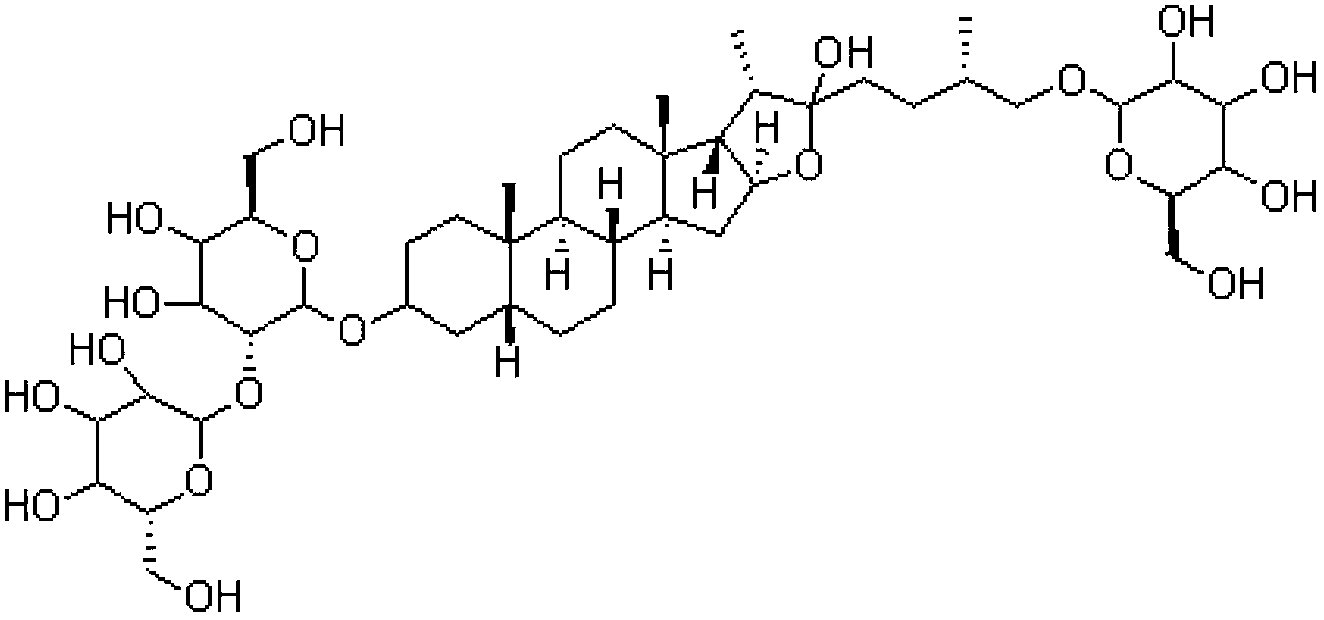

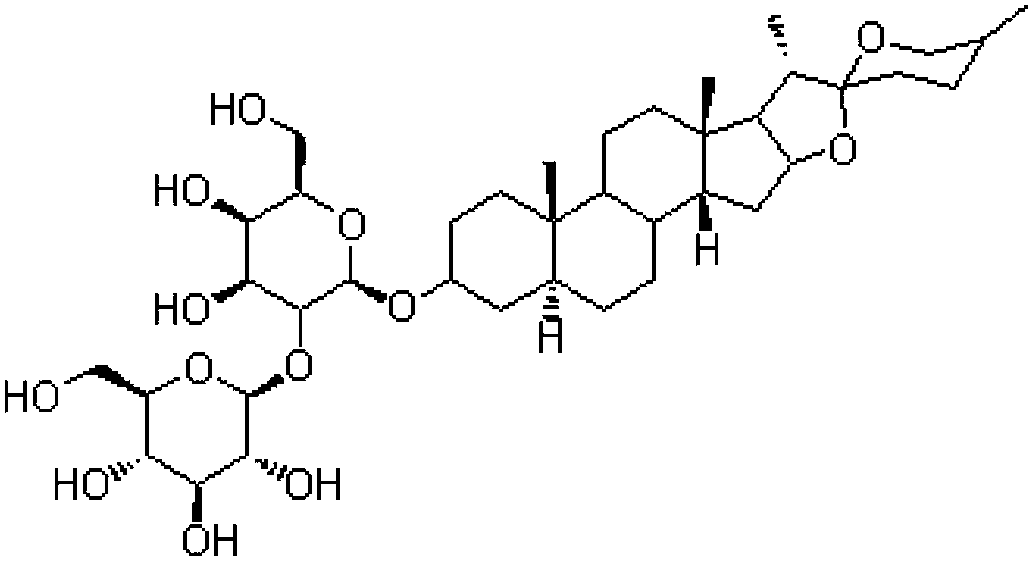

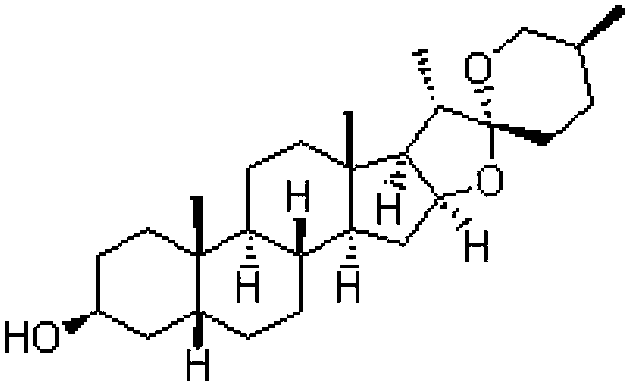

A technology of timosaponin and timosaponin, which is applied in the field of enzymatic hydrolysis to prepare timosaponin AⅢ, can solve the problems of low timosaponin AⅢ content and inability to prepare timosaponin AⅢ in large quantities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0102] Weigh 250g Anemarrhena medicinal material, heat and reflux extraction with 50% ethanol twice, each time for 2 hours, the extract is recovered under reduced pressure and the ethanol is concentrated under reduced pressure to 625mL, then added to the treated D101 macroporous resin, washed with water for 3 times the column volume Impurities were removed, followed by elution with 3 times column volume of 20% ethanol, 3 times column volume of 35% ethanol and 3 times column volume of 50% ethanol, collecting the 50% ethanol eluted part, concentrating and drying under reduced pressure to obtain The total timosaponins of timosaponin BⅡ with a purity of 58% were 11.7 grams. Add 2260 U of β-glucosidase to the total saponins of Anemarrhena, add it to 500 mL of acetic acid buffer solution with a pH of 4.50, react in a water bath at 50°C for 1.0 hour, and extract with n-butanol three times (the dosages are 500 mL, 500mL, 500mL), the combined n-butanol extract was washed three times wi...

Embodiment 2

[0104] Weigh 500g Anemarrhena medicinal material, heat and reflux extraction with 70% ethanol for 3 times, each time for 2 hours, extract the extract under reduced pressure, recover the ethanol and concentrate under reduced pressure to 1200mL, add to the processed HPD100 macroporous resin, wash with 3 times the column volume Remove impurities, then use 3 times column volume of 20% ethanol, 3 times column volume of 35% ethanol, 3 times column volume of 50% ethanol and 3 times column volume of 70% ethanol to elute, collect 50% ethanol and The fraction eluted with 70% ethanol was concentrated and dried under reduced pressure to obtain 19.8 g of total timosaponins with a purity of 51% of timosaponin BII. Add the total saponins of Anemarrhena to 6080U of β-glucosidase and mix, add 800mL of acetic acid buffer solution with pH 4.80, react in a water bath at 50°C for 2.0 hours, and extract with n-butanol 3 times (the dosages are 1L, 1L, 1L), the combined n-butanol extracts were washed...

Embodiment 3

[0106]Weigh 1 kg of Anemarrhena medicinal material, heat and reflux with 60% ethanol for 2 times, each time for 2 hours, extract the extract under reduced pressure to recover the ethanol and concentrate it to 3L under reduced pressure, add it to the processed AB8 macroporous resin, wash with water for 3 times the column volume Impurities were removed, followed by elution with 3 times column volume of 20% ethanol, 3 times column volume of 35% ethanol and 3 times column volume of 50% ethanol, collecting the 50% ethanol eluted part, concentrating and drying under reduced pressure to obtain The total timosaponins of timosaponin BⅡ with a purity of 60% are 61.2 grams. Add 22400 U of β-glucosidase to the total saponins of Anemarrhena, mix it with 1.5 L of acetic acid buffer solution with a pH of 4.80, react in a water bath at 50°C for 3 hours, and extract with n-butanol for 3 times (the dosage is 1.5 L, 1.5L, 1.5L), the combined n-butanol extracts were washed twice with 0.1mol / L NaO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com