Drying plant for corrugated paper

A technology for drying equipment and corrugated paper, applied in papermaking, papermaking machines, dryers, etc., can solve problems such as energy waste and environmental pollution, and achieve the effects of reducing pollution, saving expenses and having a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

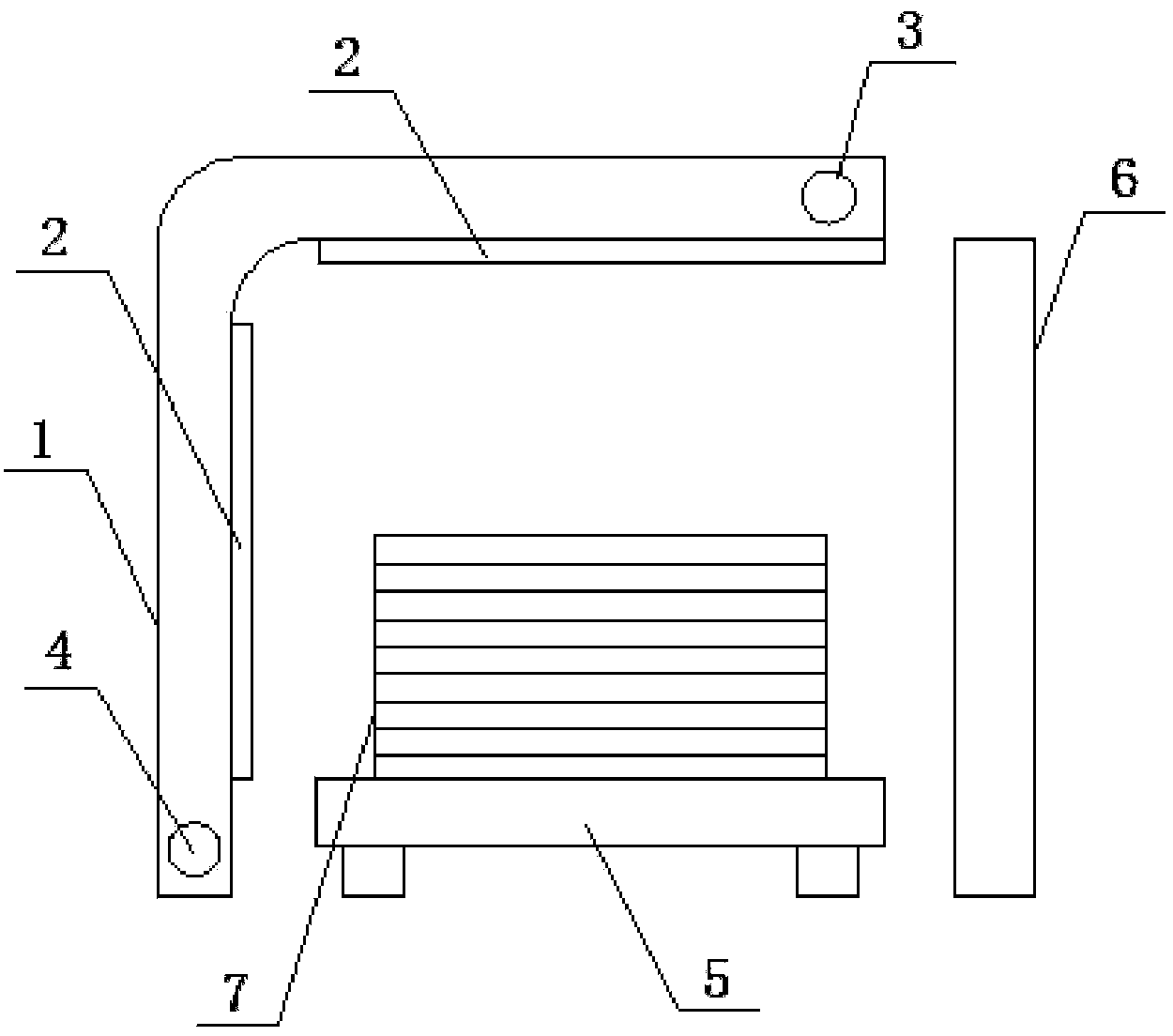

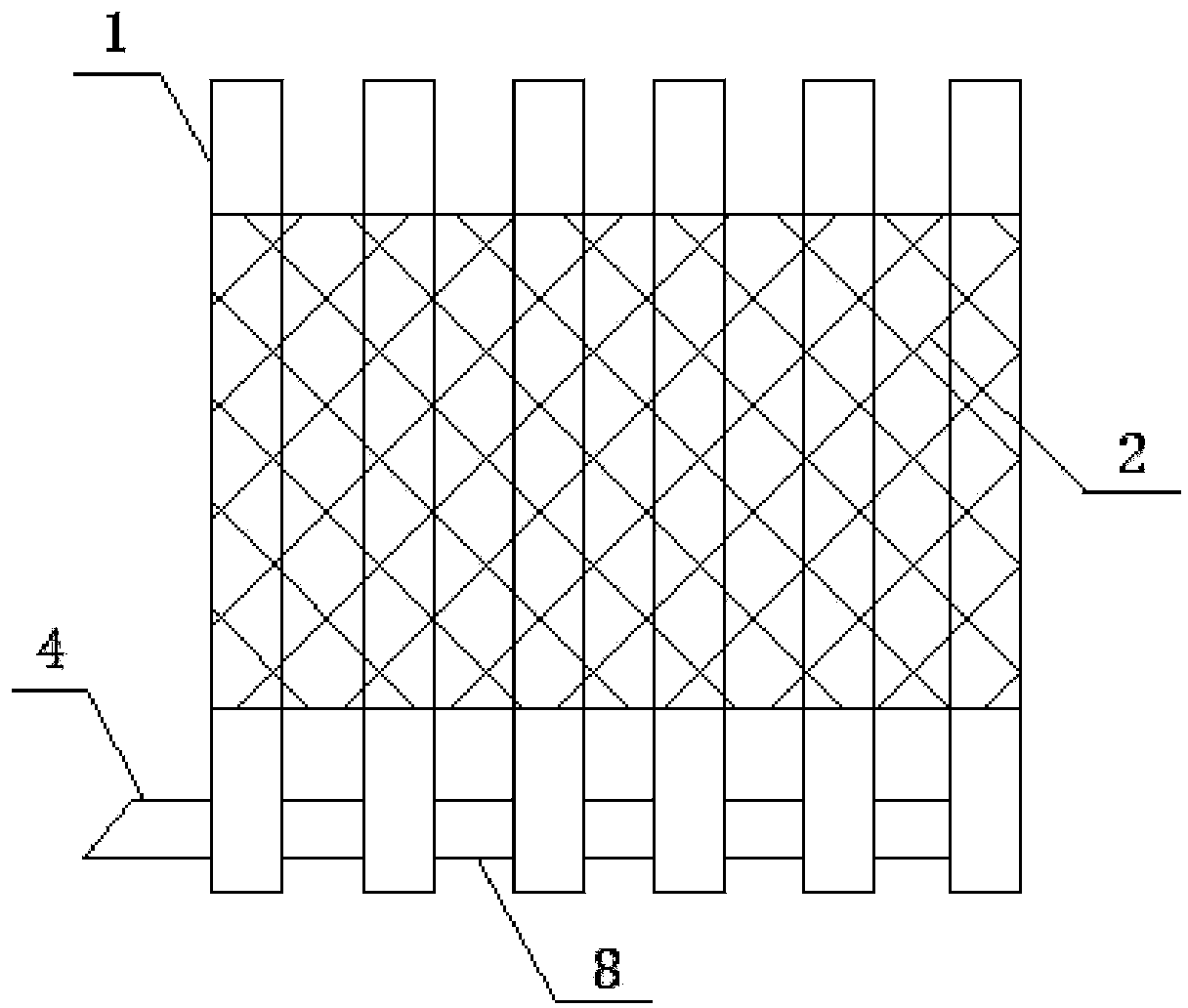

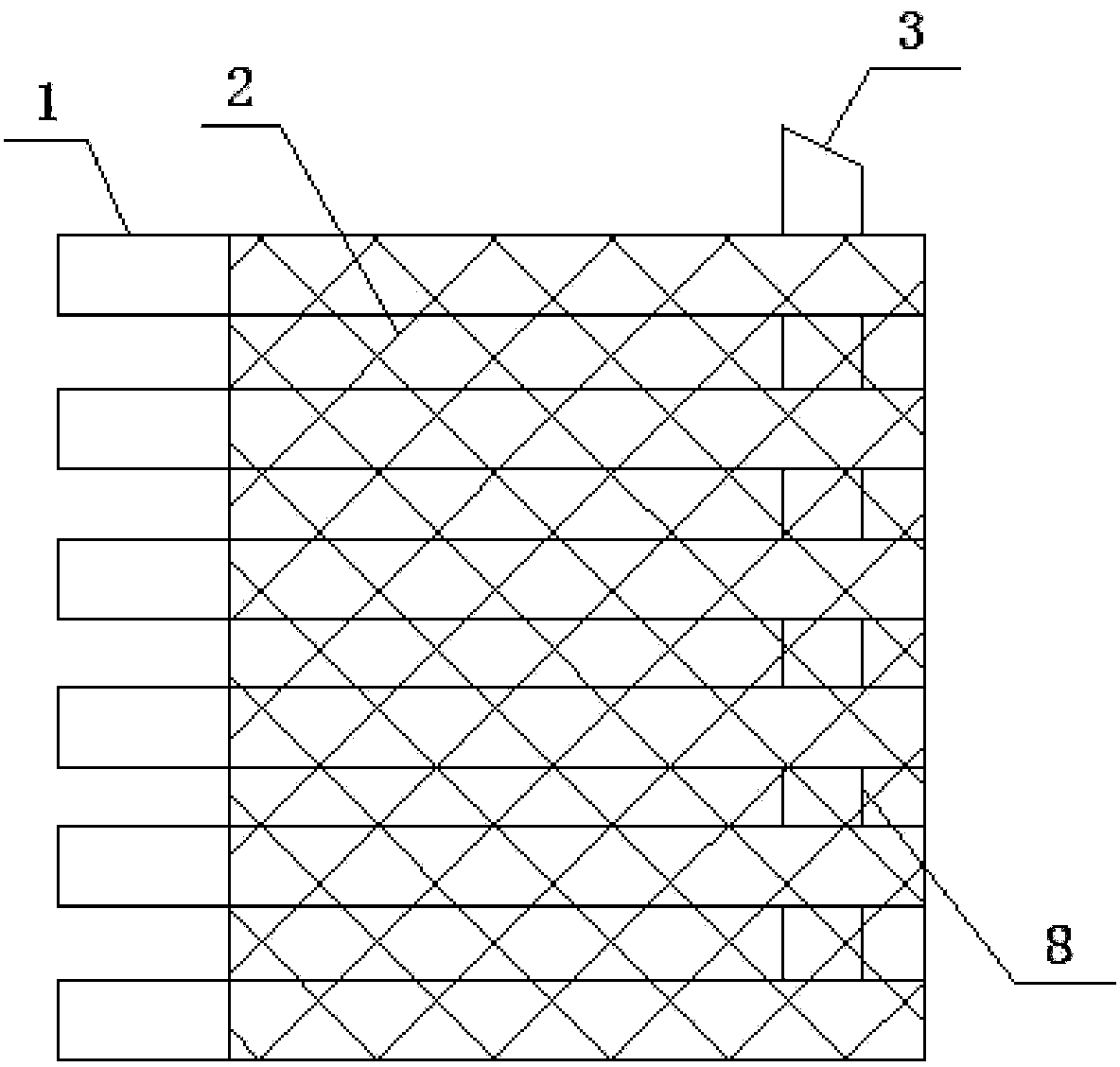

[0015] Such as figure 1 , 2 , 3, the present invention includes a drying table 5 for placing corrugated paper 7, one side of the drying table 5 is provided with a row of inverted L-shaped heat dissipation pipes 1 connected in series or in parallel, and the heat dissipation pipes 1 are connected by a connecting pipe 8 connection, the lower end of the heat dissipation pipe 1 is provided with a heat dissipation pipe outlet 4, the upper end of the heat dissipation pipe 1 is provided with a heat dissipation pipe inlet 3, and the other side of the drying table 5 is provided with an exhaust fan 6, and the heat dissipation pipe The upper end and the side end of 1 are provided with a metal protective net 2 near the side of the drying table 5, and the metal protective net 2 is used to protect the operator from being scalded by touching the radiator when placing the corrugated cardboard.

[0016] The working process of this example: the cooling pipe inlet 3 is connected to the residual ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com