Automatic installing and detaching device of drill rod of horizontal directional drilling machine

A horizontal directional drilling rig, automatic loading and unloading technology, applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of economic loss, personal safety, large frictional resistance, and large energy loss, and achieve the effect of avoiding useless work and saving energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

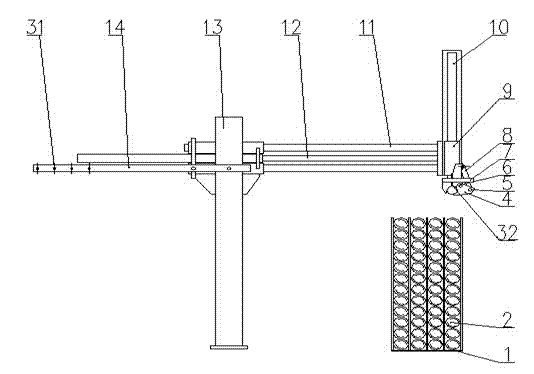

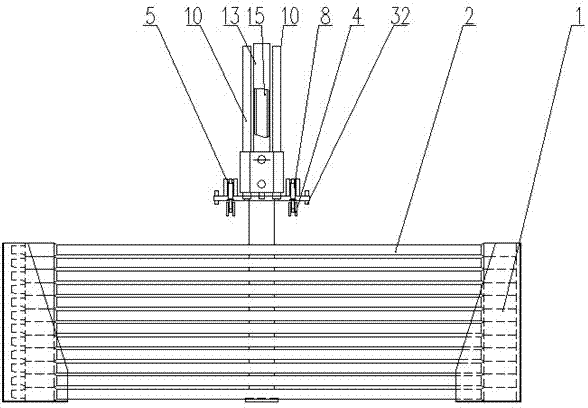

[0016] The present invention will be further described below in conjunction with accompanying drawing.

[0017] Such as figure 1 and figure 2 As shown, the automatic loading and unloading device for horizontal directional drilling rig drill pipes of the present invention includes a drill pipe box 1 and a drill pipe 2, and the drill pipe 2 is placed in the drill pipe box 1; it also includes an induction switch 3, a gripper 4, a cylinder pin 5, a pin 6. Vertical mounting base 7, grip cylinder 8, horizontal mounting base 9, vertical guide rod 10, horizontal guide rod 11, horizontal sliding cylinder 12, column 13, horizontal limit mounting plate 14 and vertical sliding cylinder 15;

[0018] The column 13 is a rectangular steel pipe, one end of which is welded with two guide sleeves parallel to each other and perpendicular to the center line of the rectangular steel pipe, and the other end is connected to the horizontal directional drilling machine through bolts;

[0019] The ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com